Modern Manners – Giving Classics Updated Handling and Power at Schwartz Performance

Everyone knows about the generation-defining weekend and music that overflowed out of the Woodstock festival in the late-’60s. For the past 15 years, there’s been a steady flow of serious horsepower and performance machines rolling out of a different Woodstock – the small Illinois town where Schwartz Performance is based.

The main building hosts the company’s chassis fabrication facility, offices, as well as a final assembly area. The back building comprises the paint booth, teardown, and final road test prep and pickup for customers.

Schwartz Performance was founded by lifelong road racer Jeff Schwartz with his son Dale. Both share a passion for road racing performance, yet also understand the importance of a safe, controllable and comfortable ride. Back in the early-2000s Jeff proved that combination by building a 1982 Cadillac Fleetwood Brougham which he and Dale drove on a number of Hot Rod Power Tours, and then really proved its merit by winning the Car Craft Magazine Real Street Eliminator in 2002.

There are two Schwartz guys behind Schwartz Performance, Jeff on the right and his son Dale. The duo is celebrating 15 years of building serious hot rods that handle yet are comfy for a cross-country road trip.

Jeff continued to push his race-car performance for the street in a white, twin-turbo, LS-powered Ultima GTR. This mid-engine beast weighed in at over a single ton with 1,000 horsepower, yet the father-and-son team cruised it again on Power Tours, followed by Jeff taking the win in the 2006 0-200-0 Silver State Classic. And, how does 211mph in the standing mile sound?

- The price of modern technology is a lot of wiring. From advanced EFI systems to digital instrumentations and modern amenities, the team at Schwartz have pretty much wired it all.

- In order to have improved quality and schedule control over their projects, Schwartz invested in a paint booth. This gives the team complete control of a build project without the worry of being held up by a paint shop.

All of these miles on road tours and shows proved to Jeff that a properly designed chassis, with the right driveline in a well-built car, could easily handle the open road yet still perform well on a track. Remember, this was the infancy of pro-touring, and most suspension kits and chassis were geared toward street rods.

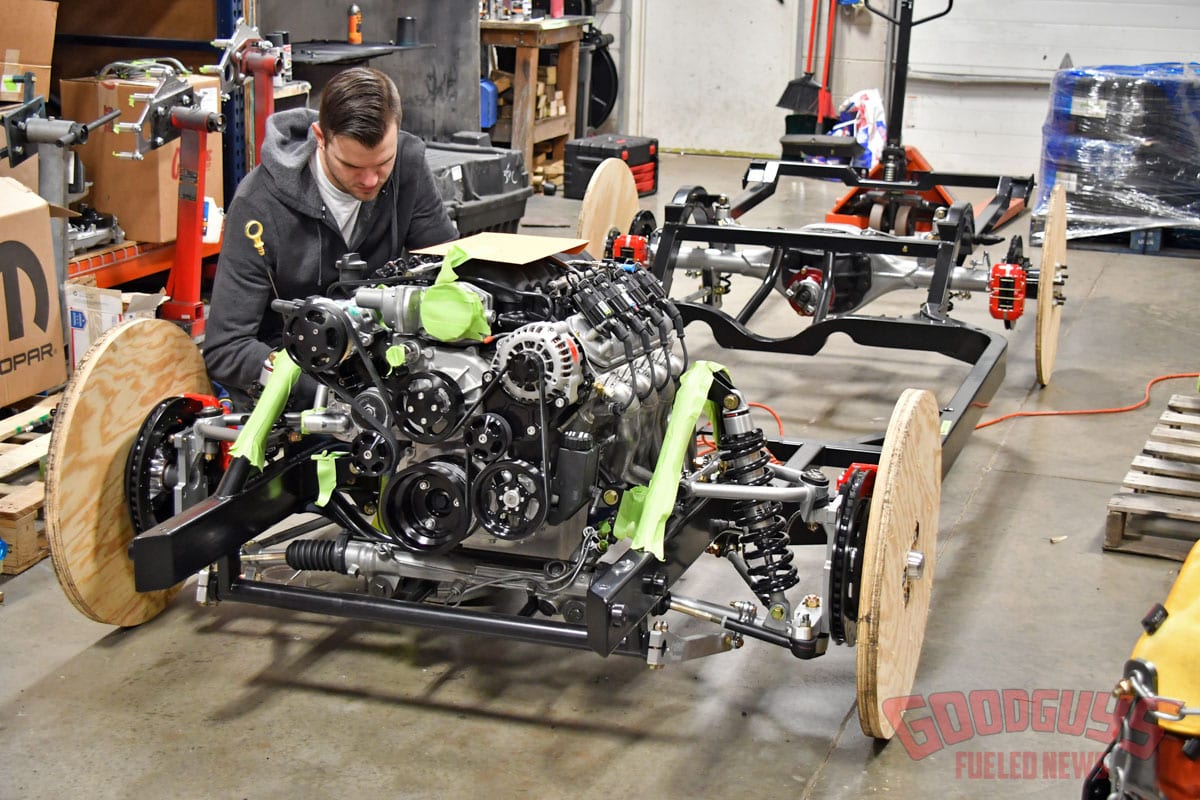

A rolling G-Machine chassis with a fresh LS3 goes through a series of quality control checks before being loaded for a customer’s home where it will be finished. Some customers go for a whole build, others want to finish the project themselves.

- The engine room is kept in a quiet corner of the shop where engines receive new cam grinds, head swaps, superchargers, and other upgrades.

In 2005, Jeff made the command decision to make his hobby and passion his career by launching Schwartz Performance. The emphasis would be to create cars that could capably handle the track while just as easily cruise the family to the local DQ. Their first customer build was Jimi Day’s 1970 Poison Dart, followed by the launch of their G-Machine Chassis for GM A-bodies the next year.

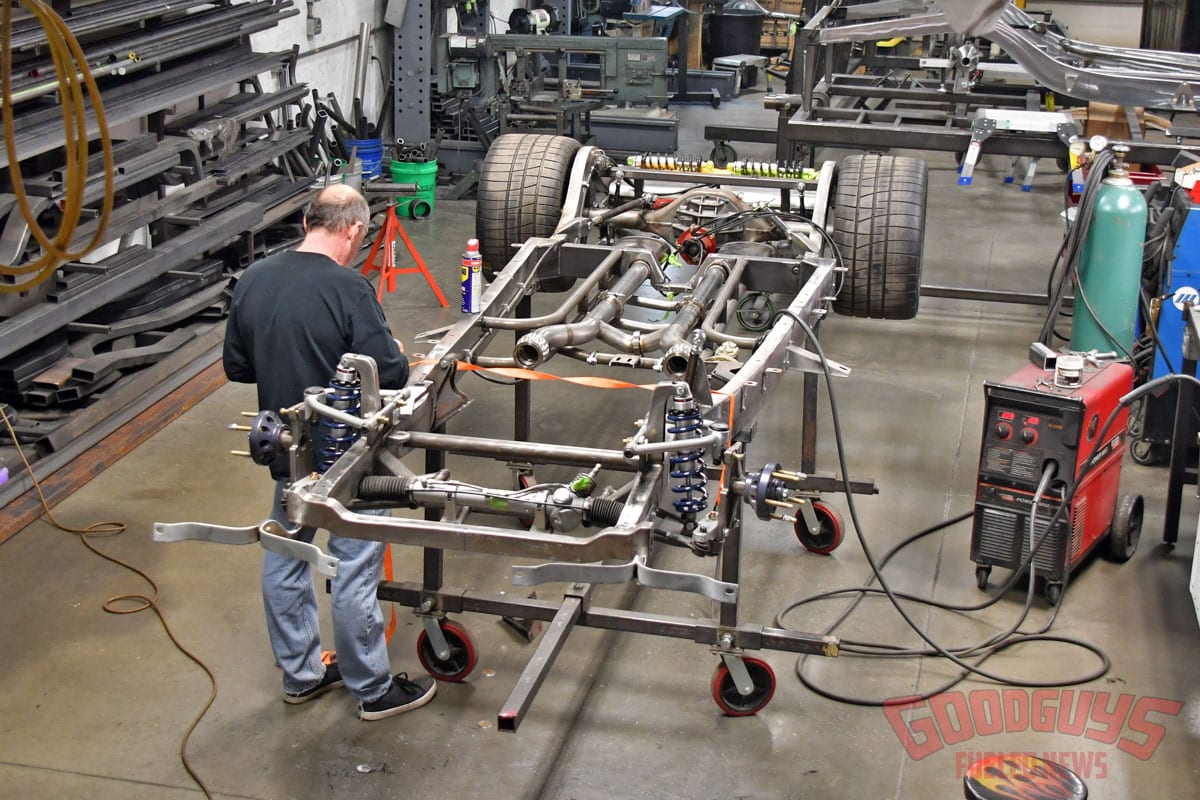

A pair of new chassis awaiting their bodies.

- Another in-house test car is this third-gen Camaro with Jeff behind the wheel at the Summet Racing Lone Star Nationals. Schwartz was on the track testing some one-off products for this body style.

- Before going into business, Jeff was a hardcore road course racer and still gets behind the wheel to attack the autocross. This is their in-house test car, a ’65 Tempest on a G-Machine chassis. It has seen plenty of laps at Goodguys AutoCross events.

By 2007 they doubled the size of their shop and launched a full “bolt-in” chassis for unibody cars with the Chevy II/Nova and first-gen F-Body. As their chassis sales and development took off, they found many customers asking if the business could source a drivetrain, recommend a painter, or even just build their car. The answer, of course, was, “Sure, we can build your whole car!”

- Schwartz Performance was founded on the premise that a hot rod should be able to drive comfortably across the country while at the same time be able to perform and handle on a road course. This is one of the company’s G-Machine chassis for a pickup getting finalized before being rolled under a cab and bed.

- The majority of the projects Schwartz builds are equipped with modern drivelines, or at minimum EFI. This Mustang will be on one of their chassis with a Coyote and a 10-speed automatic, which required a fair amount of tunnel work.

The ’63 Chevy II SS in the background is not getting a Hemi swap…only because it already has a 650hpLT4 between the fenders.

Fifteen years later, Schwartz Performance spans more than 25,000 sq. ft. shared between chassis manufacturing and project cars of all makes and models. When we walked through the shop earlier this year there were at least 15 different vehicles in various stages of build. Nearly all of the builds are based on the company’s G-Machine chassis with a modern driveline, big brakes and wheels, A/C, butt-gripping seats and clean interiors, but there was nothing in common with the makes and models.

- It may look stock, but this GTO is the definition of a modern-day muscle machine with amazing handling, an LS7 powerplant, huge brakes, and 18-inch wheels. The interior is also updated with comfortable yet gripping seats, modern gauges and amenities.

- This ’71 ‘Cuda sits on a bolt-in G-Machine chassis to handle the power from a supercharged 6.4L Hemi.

A few projects either waiting for delivery or a final sign-off on by Jeff after a several-hundred-mile test drive. There’s more than a couple we’d like to drive!

- This is Jeff’s personal project, a ’72 AMC Javelin AMX. These cars won the Trans Am Series in 1971 and 1972 with Roger Penske.

- This ’70 Buick Skylark was recently completed and features a G-Machine chassis and LS7 power with a set of 19-inch Forgelines and Baer brakes. You have to like the nod to the GSX muscle option of the day.

There was everything from a Ford woodie wagon to a ’79 Hurst/Olds, even a Hudson and two Studebakers. Hellcat engines, supercharged LTs, and a number of Coyote engines were in chassis and under hoods getting plumbed and wired. The shop has done its share of B- and E-body Mopars, classic trucks, Tri-Fives, Mustangs, and Trans Ams, even a ’29 Ford Depot Hack. No matter what the project, they are all built to be driven and enjoyed and are equally at home on the street or on a track.

Schwartz Performance

www.schwartzperformance.com

815-206-2230