Inland Attitude – No Coast Custom and Rod Shop Crafts Clean Machines from the American Heartland

If you’re lucky enough at a young age to know what you want to do in life, and you tackle the educational work to prepare for that journey, you are well on the road to reaching your goal. But, as most people know, your first job is just that – your first job. It’s simply another mile marker on your life’s trip.

For Ben VanEperen, the owner of No Coast Custom and Rod Shop in Lincoln, Nebraska, his journey had a couple of stops along the way. But today his 13-year-old business is exactly where he envisioned it would be when he enrolled in the automotive collision and repair program at his local community college years ago.

“I went to school for collision repair,” Ben says, “It’s not exactly what I wanted to do, I wanted to build cars.”

Ben worked in collision repair for a few years and did side work on other cars at night. When his employer at the time went out of business, he faced a decision. “My wife asked me what I was going to do,” he said. “She said why don’t you give it a go on your own?”

Getting Started

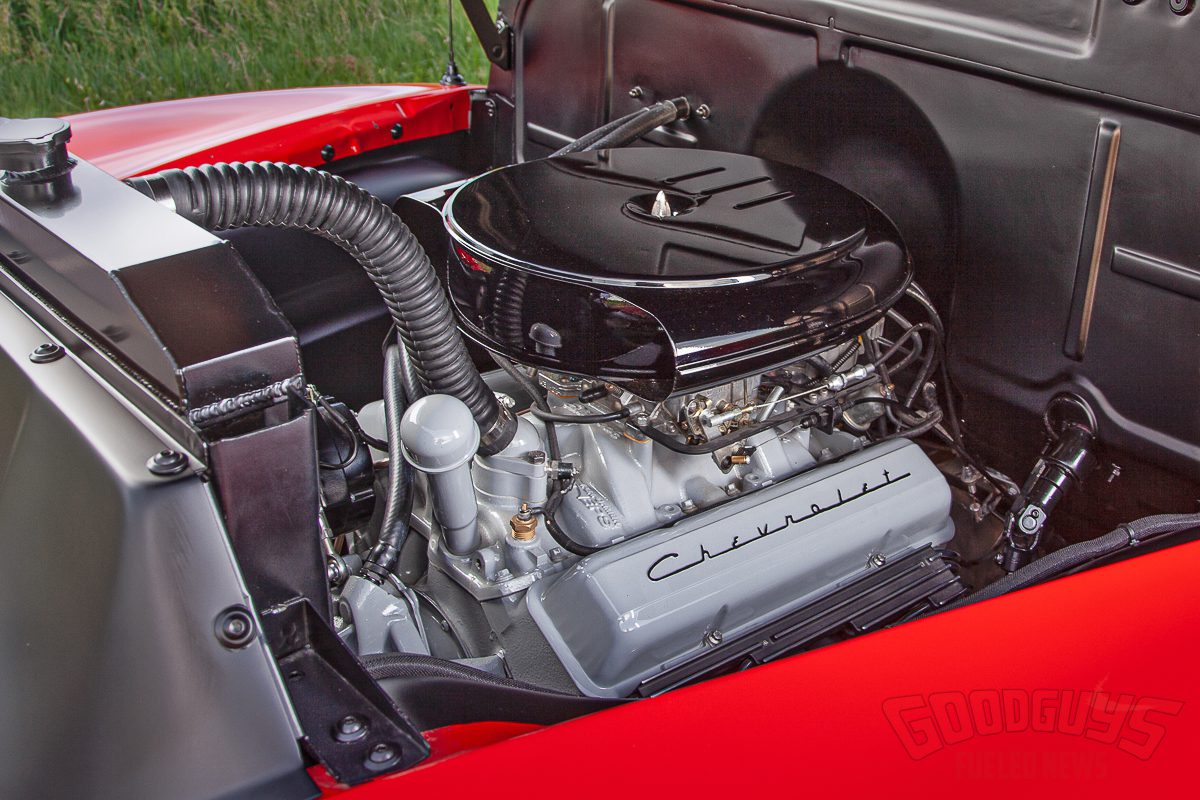

Ben opened up No Coast Custom and Rod Shop in a small commercial space. His first full build – a ’55 Chevy for a local customer – launched a steady stream of projects that now has Ben and his team of coworkers busy, with a two-year waiting list of customers. The crew handles every aspect of a build, with the exception of engine work and interiors.

A dedicated assembly area is in a separate room to help keep newly painted and polished pieces clean during the reassembly process.

Ben likes to focus on resto-mod builds with enough alterations to show off the team’s metalworking skills. For example, consider the variety of vehicles in the shop now: a ’57 Chevy, a vintage Jeepster, a ’68 fastback Mustang, a 1966 C10 pickup, a ’72 Blazer and a ’69 Camaro. Even a Porsche 356 coupe. All of them are receiving substantial metalwork.

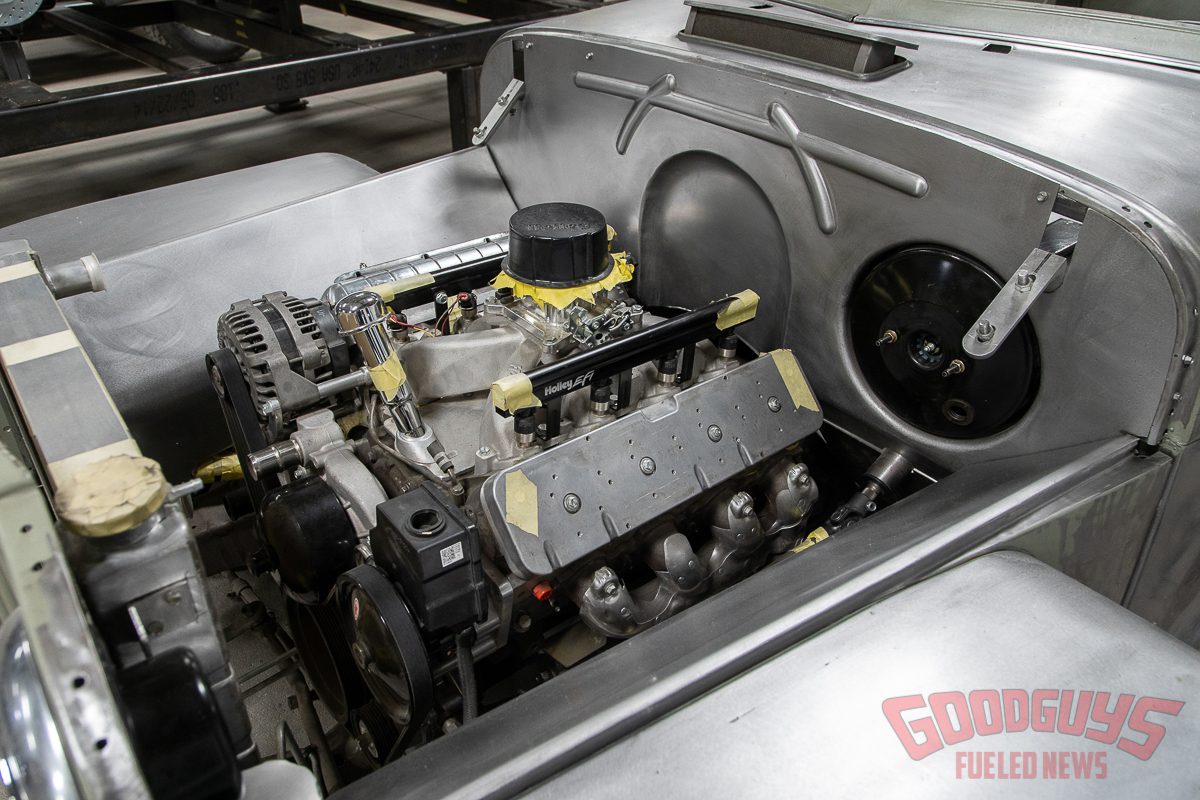

Variety keeps things interesting, as evidenced by this trio of projects in the fabrication area – a ’72 Blazer, ’68 Mustang, and an LS-powered Jeepster. Custom floors are just some of the fabricated pieces on the Jeepster.

Whatever the vehicle, Ben sees a trend that’s different from several years ago: today’s owners generally don’t want trailer queens. “The hobby has shifted where everybody wants to drive them,” Ben says. That means plenty of LS engine swaps, modern transmissions, aftermarket chassis, and other updates. He has even had customers bring older builds back for engine and chassis upgrades.

New Tech, New Options

New technologies are not limited to just the cars in the shop. Ben and his crew make use of contemporary technologies like a 3D printer, 3D scanner, and a local machining vendor (Atomic Machine and Design) to create one-off parts for many projects. For example, designing and building a custom air cleaner for a ’57 Chevy project happened faster and with less hassle by using new-tech tools. They designed the air cleaner on a computer and then used the 3D printer to create a mockup to make sure it was the right size for the engine. Once that was done, Atomic Machine created the final piece.

“The technology is a good thing and we’re using more of it,” Ben says, “but we don’t want to use it as a crutch.”

Adapting to Dual Challenges

The shop does face the same dual challenges that almost every hot rod shop wrestles with today – supply chain delays and a lack of qualified employees. Ben says he could use two or three more people, but finding highly skilled candidates who can mesh with the current team is hard. “Right now, I have the best crew I’ve ever had,” he says, “They are very talented at what they do. We mesh well. It’s an easy-going work atmosphere.”

The team at No Coast Custom and Rod Shop remains relatively small, but owner Ben VanEperen says it’s at a pretty comfortable size right now. Pictured from left to right are Ben Alberts, Chris Walker, Ben VanEperen, Melanie VanEperen, Brendan Nielsen, and Matt Gooder (standing).

Keeping the work going, though, is also impacted by suppliers facing similar issues – lack of certain components and a shortage of workers. “Everybody’s busy, (they) don’t have enough people, so everything takes a bit longer,” Ben says. “We’re adjusting to the challenge by keeping the customer in the loop.”

In addition to its first-rate metalwork, No Coast has also earned accolades for its bodywork and paint, which is all done in-house, from prep to polish.

In the pre-Covid days, most shops could operate on an almost-just-in-time system ordering parts – ordering major components a few weeks before they are needed. Not now. Suppliers are struggling to keep up. Ben says one chassis builder is almost a year behind because of these issues.

No Coast uses plenty of modern technology in its builds, but also employs old-school techniques like hand-shaping metal and using lead filler for some aspects of bodywork.

That affects the customer. Ben says most of the time when a customer commits to a build (it could often take up to two years) it’s necessary to order components like engines and chassis early, even if they won’t be installed for months.

Metal fabrication is one of the primary specialties at No Coast and the shop is equipped with specialized equipment like this Pullmax, allowing the team to build and shape just about anything.

“We order the gauge cluster, the air conditioning, the wiring,” he says. “You don’t want to be waiting on it.”

Outside Resources

Ben has some outside designers and other resources he works with on complete builds. Major projects will often get a design rendering from a professional artist. “I like to get that signed off on, and then we move forward,” Ben says. “That way we all know what we’re building, and the customer is in the loop.”

For interior work, Ben often reaches out to Tracy Weaver at Recovery Room Hot Rod Interiors in nearby Plattsmouth, Nebraska. Tracy’s team has a national reputation for producing high-end, show-winning work. “He makes an interior that fits the car,” Ben says. “We work closely with them. I kind of have an idea of where we’re going, and he incorporates that into the interior.”

Regardless of the task, Ben and his team work to a simple guiding principle: If you’re not going to do it right, then why do it? “That’s our mindset,” Ben says. “We try to go the extra step. I want these cars to last.”

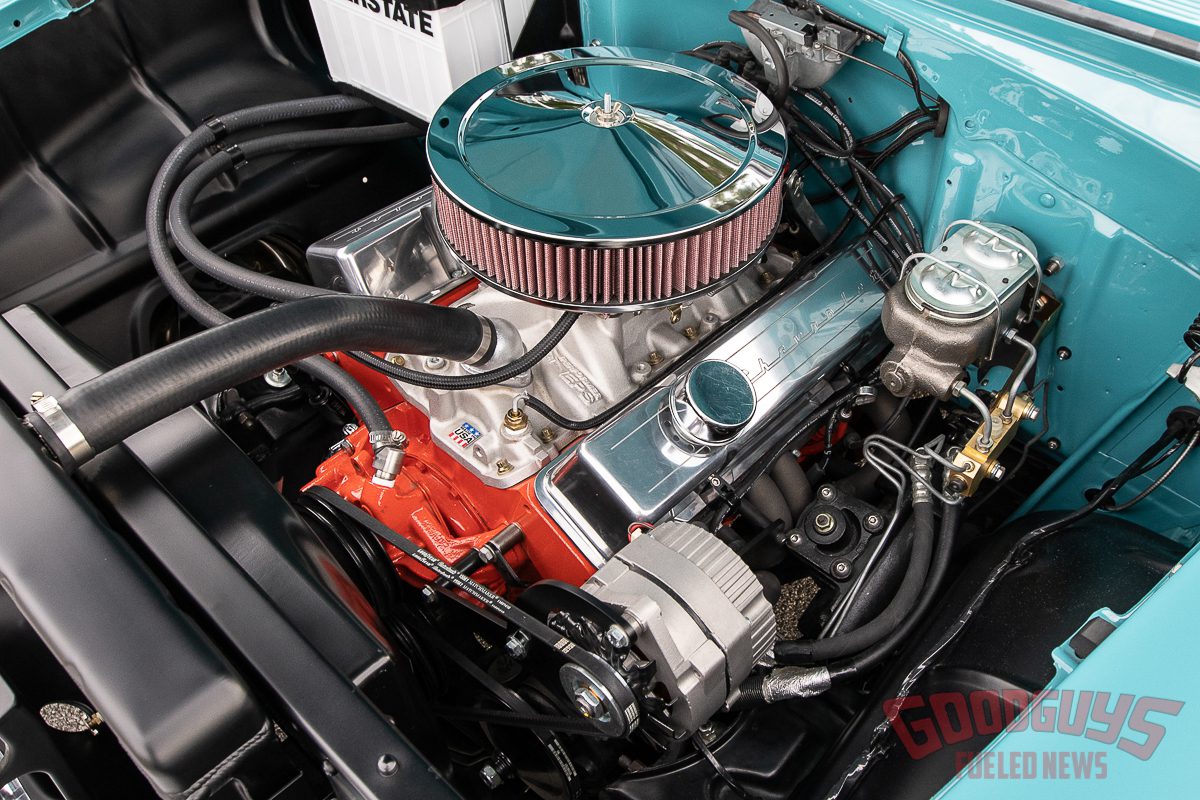

Most No Coast builds get updated in one way or another, whether it’s with custom metalwork or a modern drivetrain. This Camaro project came to the shop already painted, so the No Coast team updated it with a LS engine dressed like a vintage big block, a 4L80E transmission, Dakota Digital gauges, and Restomod A/C.

With that in mind, Ben sees a future for the shop that doesn’t include rapidly expanding. “I want to keep it smaller,” he says. “I’m not looking to grow this to 20 employees because you lose some of the personality. I see us hopefully turning out one to two cars a year, keeping with the bigger builds.”

3730 North 56th Street

3730 North 56th Street

Lincoln, NE 68504

402.325.8686

www.nocoastcustomandrodshop.com

Facebook | Instagram

Photos by Jason Lubken