Family Style At Korek Designs, Custom Cars and Trucks Forge a Strong Bond Between Customers and Crew

When Ryan Korek says Korek Designs is a family business, he’s talking about more than the decades that he’s worked with his father. He is also referring to his customers.

Korek’s best clients become long-time friends, even spending nights in his family’s spare bedroom when they come to check on the status of a build at the in New Berlin, Pennsylvania-based shop. Or when Ryan and a customer take a completed car to a big show, they usually stay at the same hotel and share evening meals.

“I’m blessed that 99.9 percent of the customers are part of the family when I’m done with the car,” Ryan says. “When clients come in to interview us, we’re interviewing them. If I won’t have dinner with you, I’m not building you a car because if I build you a car, we’re married.”

More Than a Number

More than half of Korek Designs’ clients are repeat customers, which is exactly the way Ryan likes it. “I don’t ever want to have a customer be just a number,” he says. “I want to stay a mom-and-pop shop.”

Ryan’s dad Steve started a collision repair business in New Jersey in 1977. Steve developed a strong reputation for quality bodywork and paint, both on collision repairs and on the custom race cars and hot rods he painted. Ryan picked up the torch – or, more accurately, the paint gun – and followed his father’s lead, learning to perform custom body and paint work at an exceptionally high level. In 2007, the father-and-son team moved the business to Pennsylvania and dropped collision work to focus solely on hot rods and race cars.

This ’37 Ford panel truck has been in the Korek family for more than 45 years and is Steve’s regular driver. It’s got a TCI chassis, small block Chevy power, and of course, beautiful paint.

How does the father-son partnership work? “We work great together,” Ryan says. “He’s my best friend. He’s 73 and works seven days a week. He’s always here.”

Plenty of Work

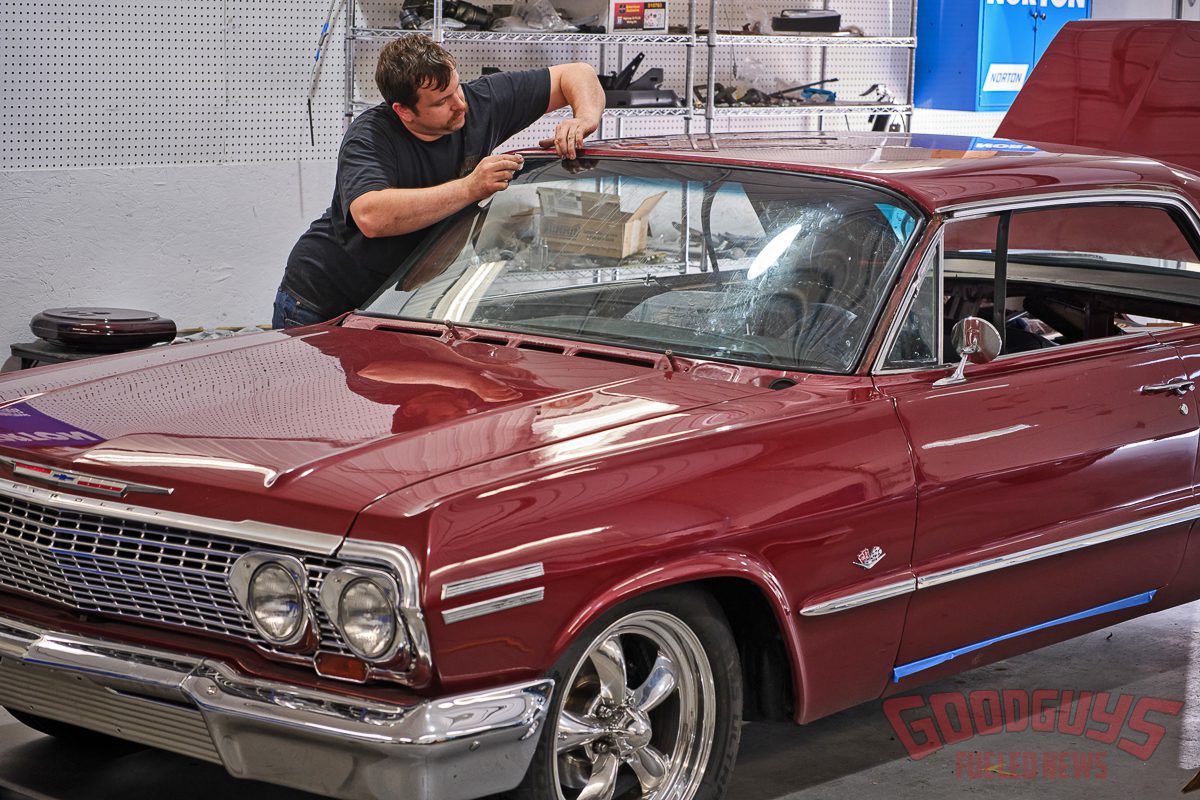

With 18 cars under construction and a full-build waiting list of close to three years, the Korek Designs staff stays busy. That means balancing the flashy paint needs for race car customers and the goal of producing timeless hot rods and customs. Ryan says cars on a race track need to be flashy and stand out from their competitors, while hot rods should have a more subdued classic style.

When we visited Korek Designs, the front showroom was home to two very different Mercurys – an old-school chopped custom, and a restored Cyclone. Both cars had their bodywork and paint done at the shop.

“I love doing the artwork (on race cars), Ryan says. “It’s a piece of canvas. They tell me one or two colors that they like. We paint a lot of cars for the PDRA Pro Stock and Pro Mod circuit.”

Korek Designs offers a full range of build services, with the exception of interior work. Ryan says they work with two upholstery shops. In addition to managing the shop’s operation, Ryan is the go-to paint person.

The in-house paint booth stays busy. That’s Ryan’s favorite part of the process, so you’ll often find him mixing paint and suiting up to spray a new finish.

“I get the cars from prime on,” he says. “I love to paint and buff.”

Plan the Build, Follow the Plan

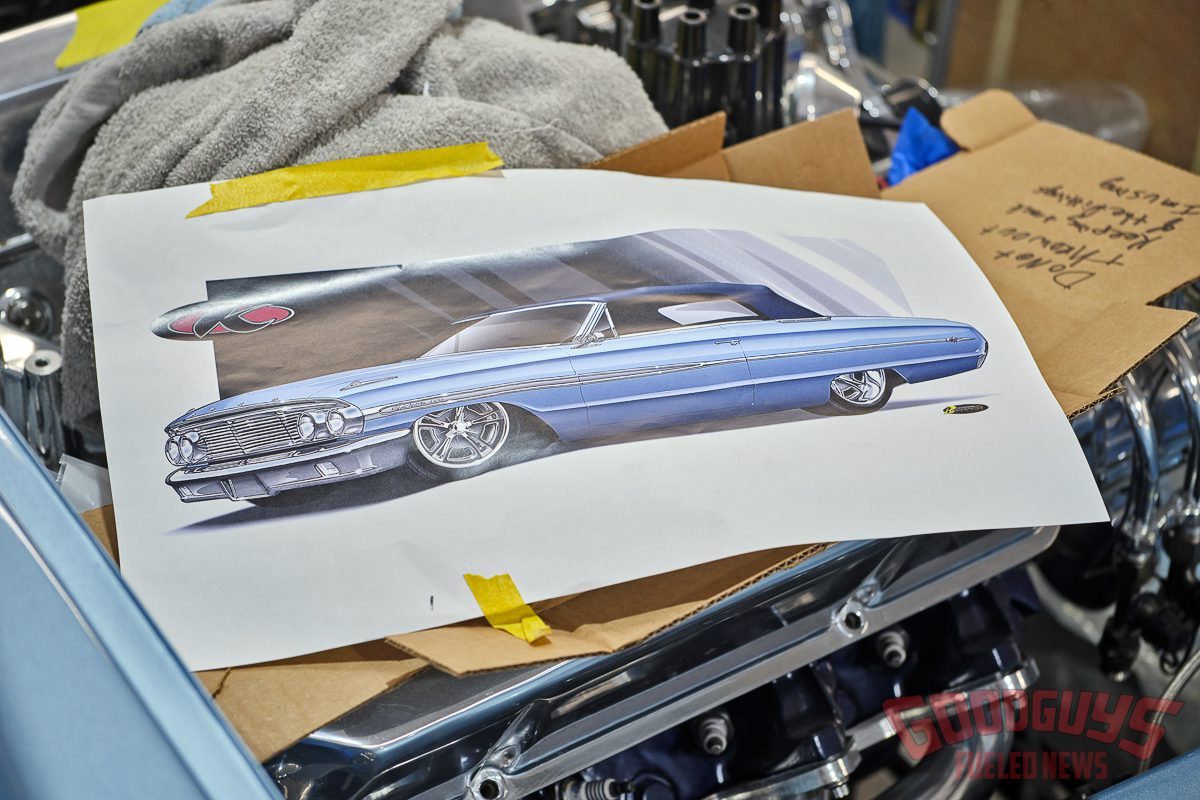

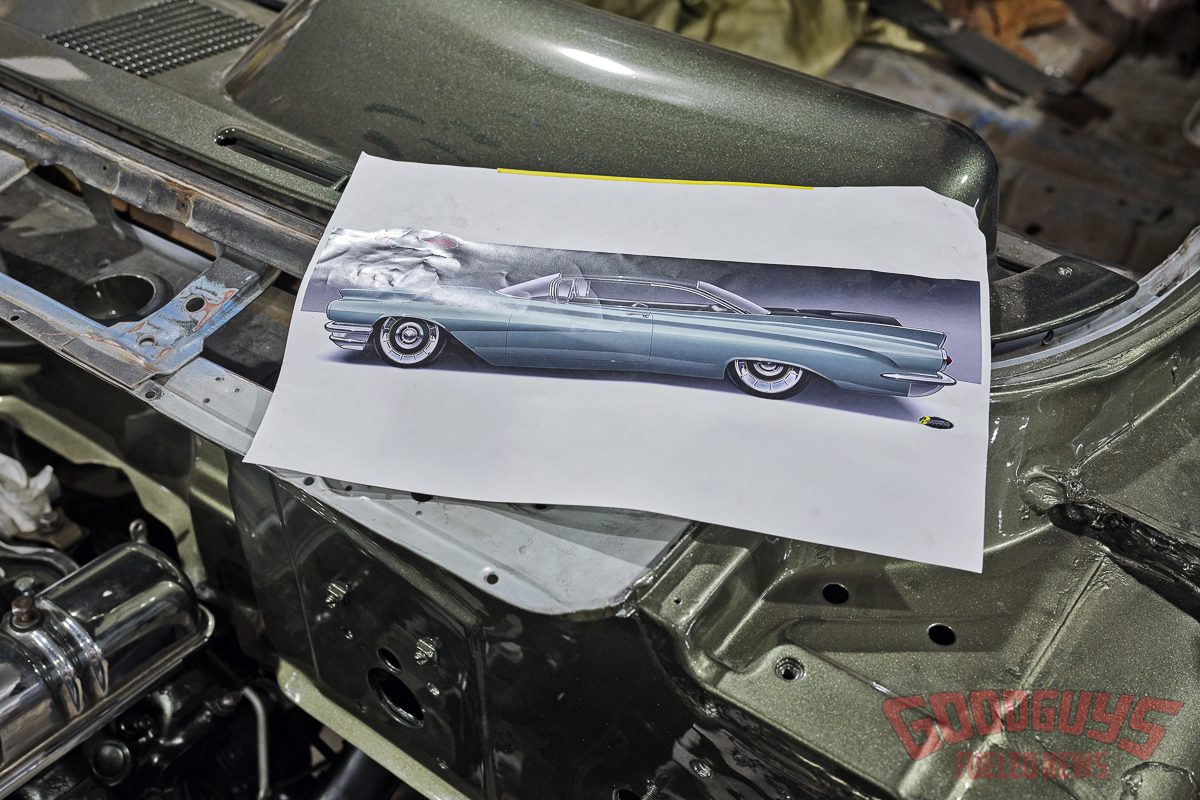

Before a car gets to the fabrication room or the paint booth, though, Ryan typically works with illustrator Eric Brockmeyer to create a rendering of what the finished vehicle will look like. It becomes a blueprint for the build. “I don’t start a project without a drawing,” Ryan says.

This Mustang fastback is getting the full treatment, from Detroit Speed suspension upgrades, to a late-model Shelby engine and a host of body mods to match the Eric Brockmeyer rendering. Ryan says it will debut in 2024.

Because nearly half of Korek’s customers are repeat customers, they often give Ryan and his team free rein on the build. Ryan does want a bit of guidance on color choice, though, because he says he has a long-term goal for each build.

“I want to build cars that don’t look dated in 10 years,” he says.

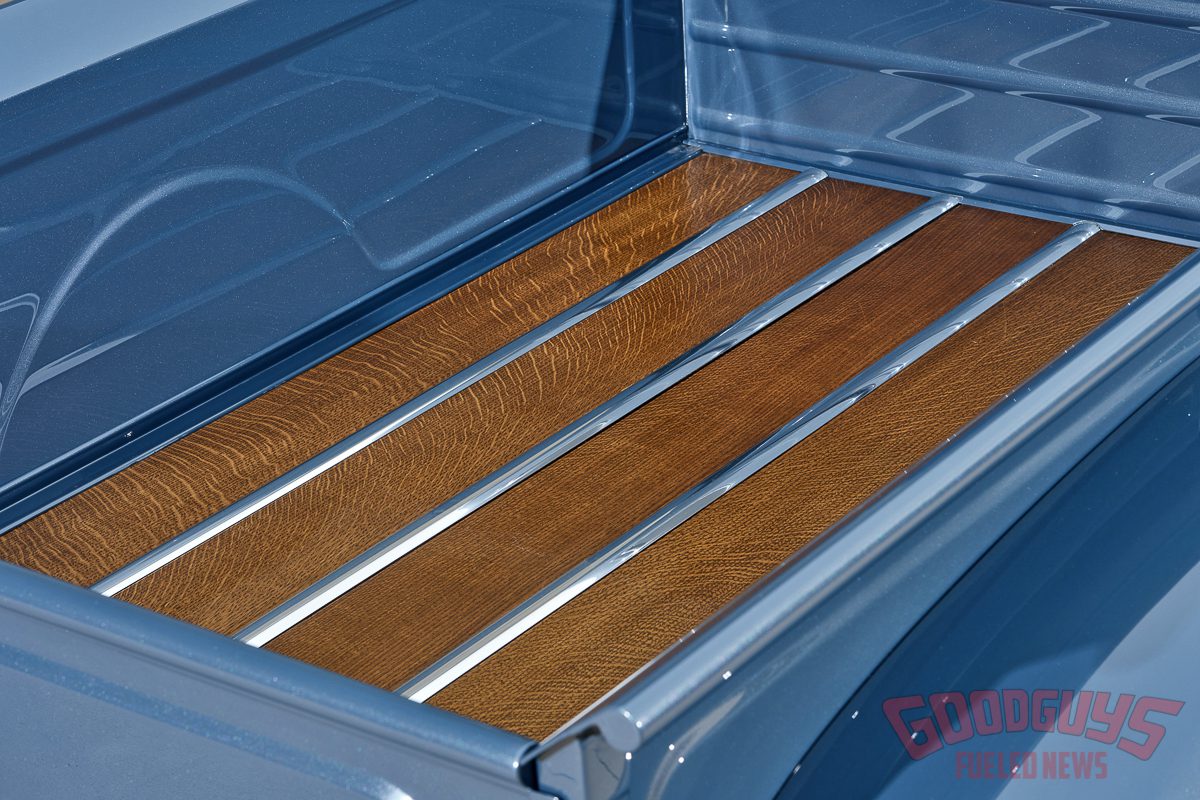

This ’58 F100 built for customer Danny Bouchard wears a lot of subtle metal mods under its bright blue PPG finish, with power from a supercharged 5.0-liter Coyote engine nestled in an Art Morrison chassis. It was crowned the Goodguys Truck of the Year Early back in 2019.

Customers are changing, Ryan says. Since Covid, many people are getting off the sidelines and getting projects started. “A lot of clients are coming in who just want what they’ve always wanted,” Ryan says. “It’s pretty cool.”

Keeping Up With Trends

While much of the work in Korek’s shop today involves cars from the ’50s and ’60s, trucks continue to be a growing trend. And the shop has developed a great track record with custom truck builds thanks in part to a ’52 International Korek finished back in 2016, and Danny Bouchard’s ’58 F100 (above), which was the Goodguys 2019 Scott’s Hotrods Truck of the Year Early. Dennis and Saun Strobel’s ’50 Ford F1 (below) was in the running for the Truck of the Year Early title this year.

“Trucks are a huge thing,” Ryan says, “but people don’t realize how much work is involved. Much more work than in a car.”

Korek doesn’t rebuild engines; the shop relies on outside sources or local rebuilders. But Ryan says they are seeing a move away from modern V8 swaps. Customers are going back to old-school power.

This ’66 Charger was finished in 2014 and really helped put Korek Designs on the map for restomod and custom builds. Highlights of the build include a modern Hemi and Reilly Motorsports suspension upgrades.

“We’re building a Nova and the guy wants me to do whatever we want, so we’re putting a 396c.i. stroker motor in it with fuel injection on top,” Ryan says.

Staying on Schedule

Despite what popular shows on television or online might depict, creating a high-end car or truck takes much more time than many people realize, often two-and-a-half to three years. Why? From sourcing parts to scheduling the work, it’s a time-consuming process.

The shop has different areas for fabrication, bodywork, paint, mechanical work, and assembly. This not only keeps things better organized, but prevents the “dirty” work from spoiling the “clean” work.

“I have to take the car completely apart. I have to take the car to the dipper, the dipper is three months out,” Ryan says. “Then I have to stalk the parts. Then we have to order a chassis; that’s about a nine month wait.”

That means managing the scheduling for the 18 cars in the shop at any one time. And while a full build can often stick to a timeline, the smaller jobs (an engine-and-transmission swap, for example) often don’t. “Small jobs often expand into larger jobs, which pushes back the scheduled builds,” Ryan says.

Like almost every shop, Ryan has to manage his staff to keep the workload progressing smoothly. That means developing the current team’s skills as well as finding future employees, either to add someone or to help develop the next generation. He has help because a technical high school is nearby. “The teachers give me the good kids, so I’ve had three or four who’ve been here for five or six years,” Ryan says.

The annual visit from the school’s students gives Ryan hope for the future. “This is the first year they were here for almost an hour,” Ryan says. “Usually, they’re here for 15 minutes. Only one would ask a question. These kids would not stop asking questions, a lot of great questions. I think the future looks good with these kids.”

Korek Design is known for first-rate bodywork and paint, so the body shop area is consistently busy with projects in various stages.

Stay in Your Lane

After decades in the business, what’s ahead for Korek Designs? Ryan says he wants to focus on the personal relationships with customers and that means avoiding the urge to grow too big. Back in 2014, when Korek moved away from a heavy emphasis on race cars to building hot rods, painter Charlie Hutton gave Ryan advice that he follows to this day.

Ryan built this ’60 Buick LeSabre for his wife, Danielle, lowering it over custom Curtis Speed wheels that get rolling with power form a 364c.i. Nailhead. The beautiful green PPG finish makes it a standout.

“He told me one thing: ‘Stay in your lane’,” Ryan says. “Don’t worry about what anyone else is doing. Just focus on what you do.”

That’s good advice, regardless of your work.

Korek Designs

1030 New Berlin Mountain Road

New Berlin, PA 17856

570.966.3100

www.korekdesigns.com

Facebook | Instagram

Photos by John Jackson