Stu Hilborn – Incredible Injector Man

Fuel injection isn’t new. Inventors of the internal combustion engine began toying with the concept in the late 1890s, and by the 1920s fuel injection had become common in diesel truck engines. During WW1 and WWII, aircraft engines employed mechanical fuel injection, as it was less sensitive to g-forces and changes in altitude.

That said, early hot rodders – the pre-WWII lakes runners, circle-track racers, and Indy 500 machines – relied exclusively on carburetor-fed power plants. It’s not that fuel injection was unknown, but there wasn’t a proven injection system that could usurp the traditional float-bowl, venturi-jet devices.

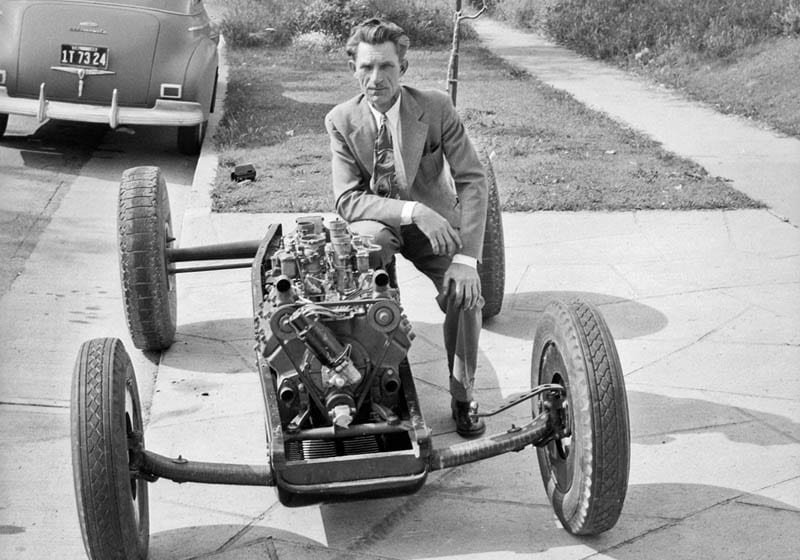

Enter Mr. Stuart Hilborn, a speed-obsessed native Canadian, who in the formative post-WWII era single handedly revolutionized racing engines – and performance – with his breakthrough mechanical fuel-injection systems.

Hilborn was born in October 1917 in Calgary, Alberta. His father was a migrant worker, who migrated the family to Southern California in the 1920s when Stu was a young child. Relocation was familiar to the Hilborn clan; Stu once counted 43 different moves.

In 1938, at age 21, Hilborn and a few friends ventured out to Muroc dry lake to catch the roadsters stirring up dust and speed. It was his introduction to hot rodding – and he was impressed. “One visit was enough,” he said. “I was hooked!”

Duly inspired, Hilborn located an engineless Model A and dropped in a breathed-on Flathead V8. This being Stu’s first foray in car building, his knowledge base was thin. As luck would have it, his neighbor was former Indianapolis 500 driver and tuner Eddie Miller. Miller shared with Hilborn his vast skill set. At the same time, Hilborn enrolled in college and studied subjects that guided the science behind the internal combustion engine – math, chemistry, and physics.

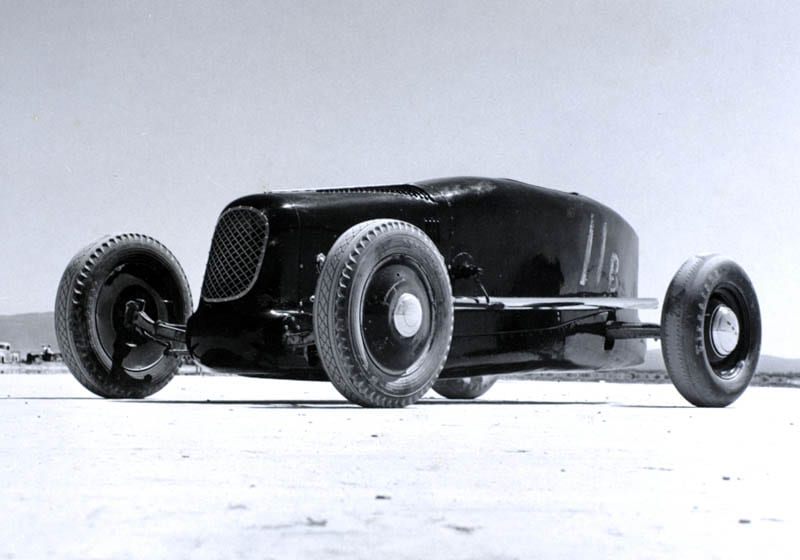

The Miller-Hilborn collaboration resulted in a rather quick lakes runner, topping 120mph. But the need for speed gnawed on him. He picked up a simple “streamliner,” less engine, for the princely sum of $75. One small problem: He finalized the transaction on December 7, 1941, a day that sent the nation spiraling into war and Stu’s streamliner sliding into storage.

Like many hot rod heroes of the time, a side effect of military service was education. Hilborn was no different. While serving out the war as an aircraft gunnery instructor, he also took note of the mechanical fuel injection systems used on aircraft engines. Would such a setup work on a racing engine? Hilborn was determined to find out.

After his discharge, Hilborn became fixated on adapting fuel injection to racing engines, the main motivation being to boost power and deliver methanol efficiently, a fuel that created more horsepower. By 1947, Stuart was back in California and ready to test his ideas in the field.

“Running carburetors with methanol was a constant problem,” he once explained to author Jim Donnelly. “The methanol reacted with the pot metal in the carburetor and turned into a white powder that clogged the jets; so, there was no venturi effect, and you lost power.”

Drawing on his science savvy, he calculated the necessary pump size to get precise amounts of fuel to each cylinder. Adapting a surplus aircraft fuel pump and his own system of nozzles, he mounted his first fuel-injection setup on his Flathead streamliner. The results were stunning. The car hit 150mph at the dry lakes (with Howie Wilson driving), becoming the first hot rod to break that elusive mark.

Sadly, Hilborn lost control of the streamliner on a test run and broke two of his vertebrae, ending his career behind the wheel. But his innovation had captured the attention of engine builders across every type motorsports. Lakes racers, dragsters, and midget racers were quick to adopt Hilborn injection.

Sadly, Hilborn lost control of the streamliner on a test run and broke two of his vertebrae, ending his career behind the wheel. But his innovation had captured the attention of engine builders across every type motorsports. Lakes racers, dragsters, and midget racers were quick to adopt Hilborn injection.

In 1948, Hilborn designed a system for the dominant 105c.i. Offy used by midget racers. A dyno test by Meyer & Drake (Offy makers) demonstrated that injection boosted power by 10 percent. They signed on as dealers instantly. While success on the midget track was a given, Hilborn injectors made their mark most prominently at Indianapolis Motor Speedway.

Hilborn injection arrived at the Brickyard in 1949 on a 270 Offy-powered roadster driven by Jimmy Jackson. Using injection only for qualifying, Jackson set the 7th fastest time, 128 mph. The next few years a handful more teams adopted injection, including the Ferrari entry. Victory came in 1953 when Billy Vukovich dominated in his Kurtis roadster. That opened the floodgates of success. Since Vuky’s maiden win, Hilborn injectors have powered 34 Indy 500 champions!

For the following decades Hilborn perfected his injection systems, adding applications in nearly all forms of motorsports, from motorcycles to boats. Using injection became de rigueur, the first choice for fuel delivery. (Well, not everyone. NASCAR held fast to carburetors until 2012.) During this period, Hilborn Fuel Injection the company thrived as well, developing and offering both mechanical and electronic systems. To this day, a stack of Hilborn injector inlet tubes is a badge of honor for any hot rod or muscle car.

It’s difficult to imagine another individual who changed the face of motorsport as much as Stuart Hilborn did. Hilborn, who passed away in late 2013 at age 96, was inducted into the Specialty Equipment Market Association (SEMA) Hall of Fame, as well as the Hot Rod Magazine Speed Parts Hall of Fame.

Let’s have another legend of hot rodding, and a contemporary of Hilborn, have the final word. Alex Xydias, founder of So-Cal Speed Shop in 1946, recently had this to say:

“Hilborn was a very nice and very bright guy. Our cars never ran his injection, but I used to visit him in his shop at night and watch him work, learning as much as I could. He was first to break 150 at the lakes. He was a hero to me.”

And to all of us, as well.