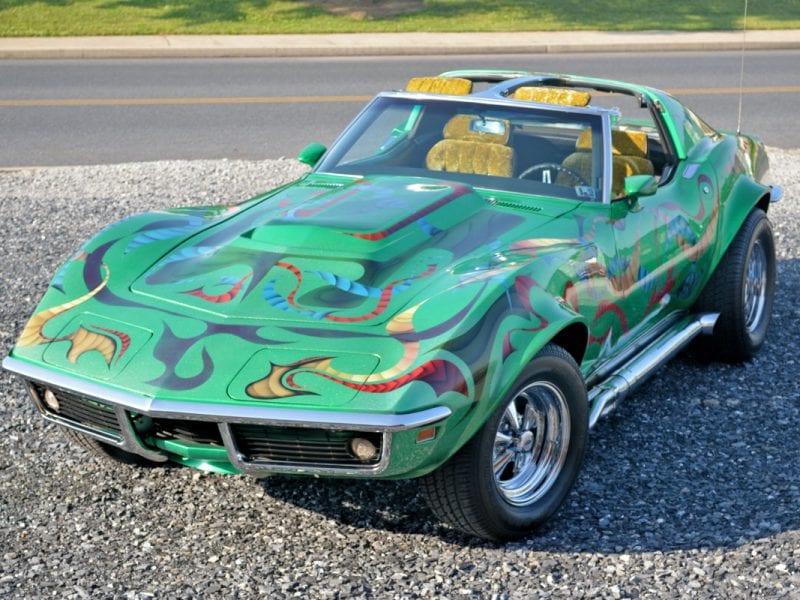

Slippery Stingray – Sliding From Stock to Slick in Jim Kerr’s ’69 Corvette

We all know that hot rodding can be a slippery slope. Plans for simple engine mods often turn into a major rebuild or an upgrade to a completely different power plant. And a basic repaint can quickly escalate into a complete frame-up rebuild.

Jim Kerr has become all too familiar with the hot rod snowball effect over the past couple of years. The Hastings, Nebraska resident can still remember the days not so long ago when he would stop by local shop Snyder Street Rods and shake his head at the amount of money and energy guys put into their cars. Then he jumped into the fray himself.

Jim’s initial plans were much more modest when he first found this ’69 Corvette Stingray. The ’Vette was a clean big block survivor and Jim’s intention was to have the car repainted, clean up the interior, and quickly flip the car. When the Snyder Street Rods team of Mike Snyder and Dean Gerberding began stripping the car down and realizing how clean it was, Jim started to reconsider. The decisive shift happened while Jim was attending the Goodguys Heartland Nationals in Des Moines with Mike and Dean.

“I was watching autocross and got intrigued,” Jim says. “While walking down vendor row we stopped at RideTech’s booth and it was over from there out.”

Before long, Jim’s Stingray was being fitted with RideTech front and rear coil-over suspension systems, Wilwood six-piston front and four-piston rear disc brakes with drilled and slotted rotors, and a Borgeson power steering box. Naturally, the frame itself was fully welded and smoothed, as well, while the front crossmember was sectioned to lower the engine, with oval tubing welded in for the A/C and heater hoses to run through.

The crossmember modifications were necessary to keep the Nelson Racing-built big block under cover without slicing up the original big block hood. The 502c.i. mill was also slid back 2-inches and a custom Stef’s oil pan was used for ground clearance. The big block was topped with a Nelson Racing Alien intake which, when combined with the Holley EFI controls and crank-trigger ignition, McJacks headers, and other goodies, cranks out 608 horsepower.

Engine support pieces included a Vintage Air front runner system (spaced 1-inch forward from the block to allow the top radiator hose to pass between the block and alternator to the custom thermostat housing), and a custom copper/brass radiator mounted in a sectioned radiator support to fit further forward. A Quick Time bellhousing and McLeod dual-disc clutch were used to connect the big block to the Tremec TKO 600 five-speed transmission.

The body had no signs of previous damage but was still treated to plenty of massaging to ensure the panels were exceptionally straight and well aligned. Subtle modifications included a recessed and smoothed firewall, enlarged transmission tunnel, filled rear exhaust opening, smoothed hood bottom, and a Detroit Speed electric headlight door conversion. Paint was handled in-house at Snyder’s Street Rods using one of the distinctive PPG colors developed by Randy Borcherding at Painthouse – a brilliant hue dubbed Super Duper Blue.

That bold blue finish was contrasted with bright red Alcantara leather upholstery stitched by Eddie Potestio at Eddie’s Rods and Customs in Pueblo West, Colorado. Eddie not only wrapped the recontoured seats in the bright Hydes material, but also covered the dash, console, and door panels. Dakota Digital VHX gauges filled the original dash panel and a Vintage Air Sure Fit system was added for extra comfort. Finishing touches included a Billet Specialties wheel and Lokar pedals.

The bright red upholstery was complemented with redline tires from Diamondback, sized at 245/45/17 and 275/40/17 to wrap around 17×8- and 19×9.5-inch Schott wheels. The combination brings to mind classic Hot Wheels cars from decades ago.

The end result is a sleek restomod Stingray that’s distinguished by its bold color and attention to detail. “Almost all the custom work and engineering to this car may go unnoticed due to it all being done to chassis and underneath the vehicle,” Jim says. “This whole build was 1/8-inch here, there, and over there.” In addition to the Snyder Street Rods team, Jim and his wife Barbara offer credit and praise to TJ at Atomic Machine, Eddie Potestio, Tom at Nelson Racing Engines, Randy at Painthouse, and Chad at The Shop, Inc.

Yes, hot rodding can be a slippery slope. That’s not necessarily a bad thing when it results in a sleek and slick custom Corvette like this one. As he blasts down the highway in this big block brute, we’re pretty sure Jim Kerr has few regrets about going all-in on this slippery Stingray.

Photos by Damon Lee