Custom Covers – A Close-Up Look at Building Custom Inner Fenders

Some custom modifications on our vintage cars and trucks are born out of necessity, some stem from desire, and many are a little of both.

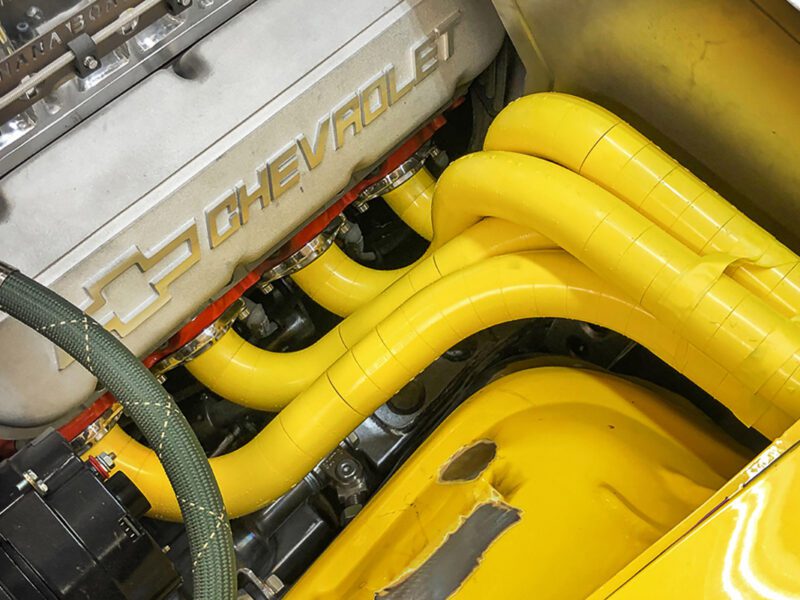

Take the custom inner fenders on the Goodguys Grand Prize Giveaway Squarebody ’85 Chevy pickup, for example. The low stance of the Roadster Shop Slammed SPEC chassis required a custom inner fender solution so we could run 20×10-inch B-Forged wheels and 265/35/20 tires without rubbing or interference. Deleting the inner fenders was not the solution we wanted. And while there are off-the-shelf inner fenders are available, the Goolsby team decided this was one area where they could put their custom fabrication skills on display.

The custom inner fenders crafted at Goolsby Customs not only solve a problem, they look great doing so. Like any good custom modification, these pieces appear to belong – they fit the space well and almost have an OEM feel thanks to the clean shape and well-placed beads and raised panels lending some design and distinction. The result is a better-than-OEM appearance – something that actually looks much cleaner than most mass-produced factory parts.

The custom inner fenders crafted at Goolsby Customs not only solve a problem, they look great doing so. Like any good custom modification, these pieces appear to belong – they fit the space well and almost have an OEM feel thanks to the clean shape and well-placed beads and raised panels lending some design and distinction. The result is a better-than-OEM appearance – something that actually looks much cleaner than most mass-produced factory parts.

The Goolsby team did a great job of chronicling how these inner fenders were built, so we thought it would be cool to show you the behind-the-scenes process as part of our metalworking section. Not only will this help you appreciate the fabrication skill that goes into custom parts like these, it might also give you some ideas on how you might approach making similar parts for your own ride. And if that seems overwhelming, you can look for bolt-on solutions like this Slosh Tubz install. For now, though, let’s look at how seasoned metal craftsmen approach building custom panels like these.

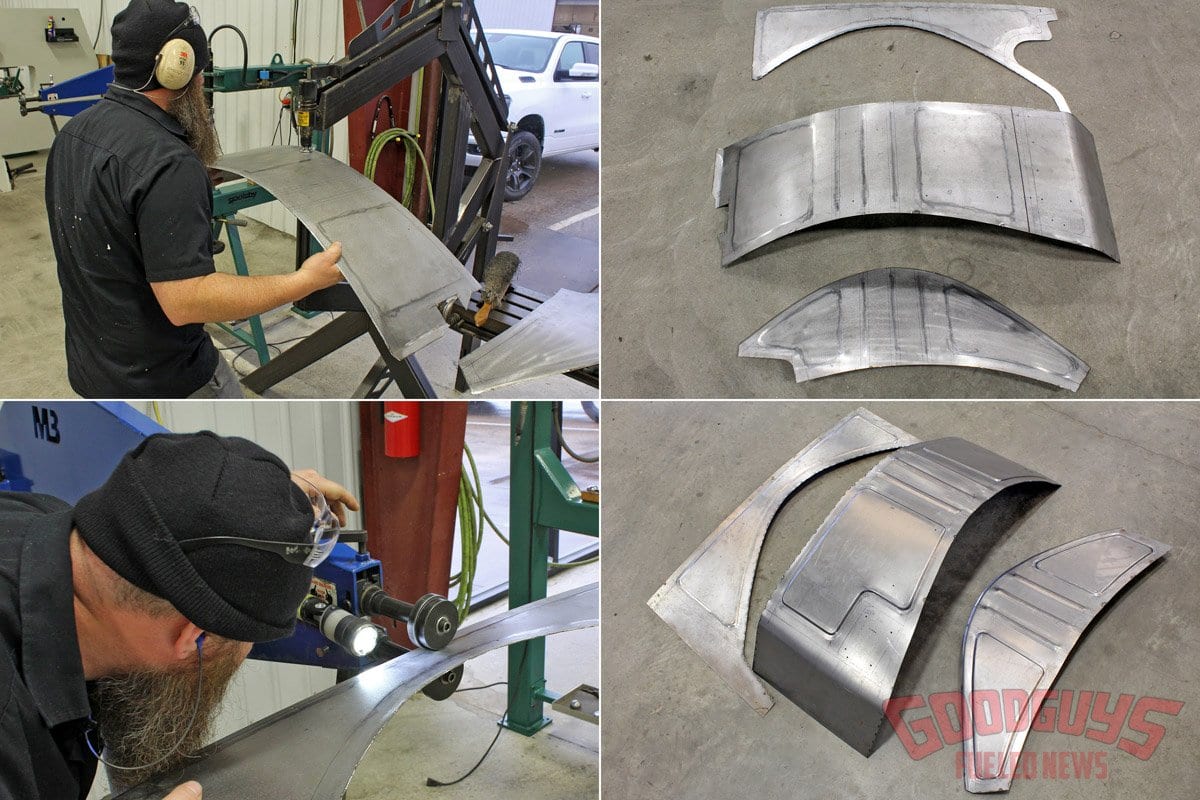

To start, the Goolsby team determined how much additional clearance was needed on the back side of the fenders. The inner structure of the fender was then trimmed accordingly, and filler panels built and welded in to finish off the back side of the fender.

From there, main arch and vertical filler panel of the new inner fender assembly were initially mocked into place. The team started with cardboard templates, then those shapes were transferred to metal, with the main arch matching the height and shape of filler panels built in the first step. The vertical filler panel and main arch were then tack welded together and held onto the fender using metal clamps. Note also the temporary flange tack welded to the main arch, which will help as the next panel is built and attached.

- The next panel was the large, angled piece that leads from the main arch down toward the frame. Look closely and you’ll see a slight lip on its top edge, which will allow it to eventually be butt-welded to the main arch panel.

- Here’s a look at the initial three-piece assembly off the truck and on the bench. Note the line at the bottom marking where the angled panel needs to be trimmed.

A short vertical piece was needed to finish the assembly and connect the angled section to the frame, Again, a cardboard template helped determine the initial shape before it was cut out in metal. Then it was temporarily clamped to the frame. A temporary flange on the upper portion of the panel will aid in mating it up to the main assembly.

This photo of the inner fender assembly shows how the three main pieces came together. At this point, the pieces were still tack welded together, as they needed to come apart again so that beads and stepped sections could be rolled into them. The outlines of those bead lines have been marked on these panels.

With the pieces cut apart again, a planishing hammer was used to stretch the metal along the lines where the beads and raised panels would be rolled. This prevents distortion when using the bead roller to create the beads and raised panel sections. These beads and raised panels not only look good and create a more finished appearance, but also strengthen the metal and prevent it from easy denting and annoying oil-can flexing.

After tack welding the inner fender pieces back together, the assembly was test fit in the truck again so any final trimming and adjustments could be made.

After final welding and dressing the welds, the result was a pair of great-looking inner fenders that will provide additional clearance, plenty of strength, and a custom finishing touch. We’re almost disappointed that all of this cool custom metalwork will be covered up with paint!

Photos by Goolsby Customs