Simplifying Custom Header and Exhaust Construction with Icengineworks Precision Exhaust Modeling Systems from Trick-Tools

There are plenty of complicated and involved processes when building a hot rod or custom car or truck. Fabricating a custom exhaust system often ranks among the most time-consuming and tedious aspects of a build, especially when you’re dealing with tight engine compartments and limited clearance on lowered vehicles. You measure, bend, cut, trial fit, and frequently invest a lot of effort and materials to get things right.

The team at Icengineworks knows all about the time vacuum of custom exhaust building and has developed an efficient modeling system that many fabricators consider cheating. This modeling system works in conjunction with pre-bent stainless steel U- and J-bends that can be cut and spliced to build complicated header and full exhaust configurations.

The modeling blocks are available in a variety of different kits with a quantity of blocks based on the prospective project (basic header, full header, etc), as well as different diameters (1-5/8-, 1-3/4-, 1-7/8-, 2-inch). The blocks come in different angles, so you can model straight lengths and bends with different radii.

The Exhaust Modeling Block system allows fabricators to build a plastic model of their exhaust before having to cut or weld the metal tubing. Block kits include straight and radiused blocks with varying centerline radii that simply snap together and can be rotated to any angle to avoid obstacles, allowing you to assemble a custom exhaust model tailored to your vehicle. Each block features index marks that signify when blocks are aligned in the same plane-of-bend and assist in tracking part rotation during the fabrication process. Specific kits are available for building headers, turbo manifolds, and full exhaust for designing a complete exhaust system.

Index marks on each block aid in maintaining proper orientation, allowing you to see when blocks are aligned in the same plane of bend, and helping to determine rotation angle. Reference points can be transferred to the metal tubing when it’s cut, which helps when assembling and welding the final pieces.

Assembling the blocks allows you to mock up primary header pipes or other exhaust pieces, tailoring them to fit your vehicle, avoid obstacles, and maintain equal primary tube length. They can also be helpful for designing and routing exhaust pipes in tight-fitting chassis.

After making a block model, it’s much easier to cut and weld the exhaust pieces together to match your template. Precise cuts are key for proper fitment, and Icengineworks also offers tube cutting jigs to simplify this process. The jigs allow you to cut pre-bent tubing perfectly square to the bend tangent using a standard vertical bandsaw. This allows for a precise fit and easier welding of segments. The cutting jigs have an aluminum cutting board that’s designed to run along the fence of a vertical band saw, as well as alignment blocks that fit specific centerline radius mandrel bends.

Then you transfer the different segments of your template to metal tubing. Icengineworks can make this process easier, too, with tube cutting jigs that work with your vertical bandsaw.

Once your block segments have been transitioned into metal, Icengineworks also has tack weld clamps you can use to test fit, adjust, and clock the pieces before they’re tack-welded together. These clamps are a great way to eliminate cut-and-weld adjustments and are big time savers during the final welding process on any exhaust project. Collector clamps are also available to hold header primary tubes or modeling blocks.

These clever tack weld clamps are another Icengineworks offering that help you test fit, adjust, and clock your tubing sections together before tack welding them.

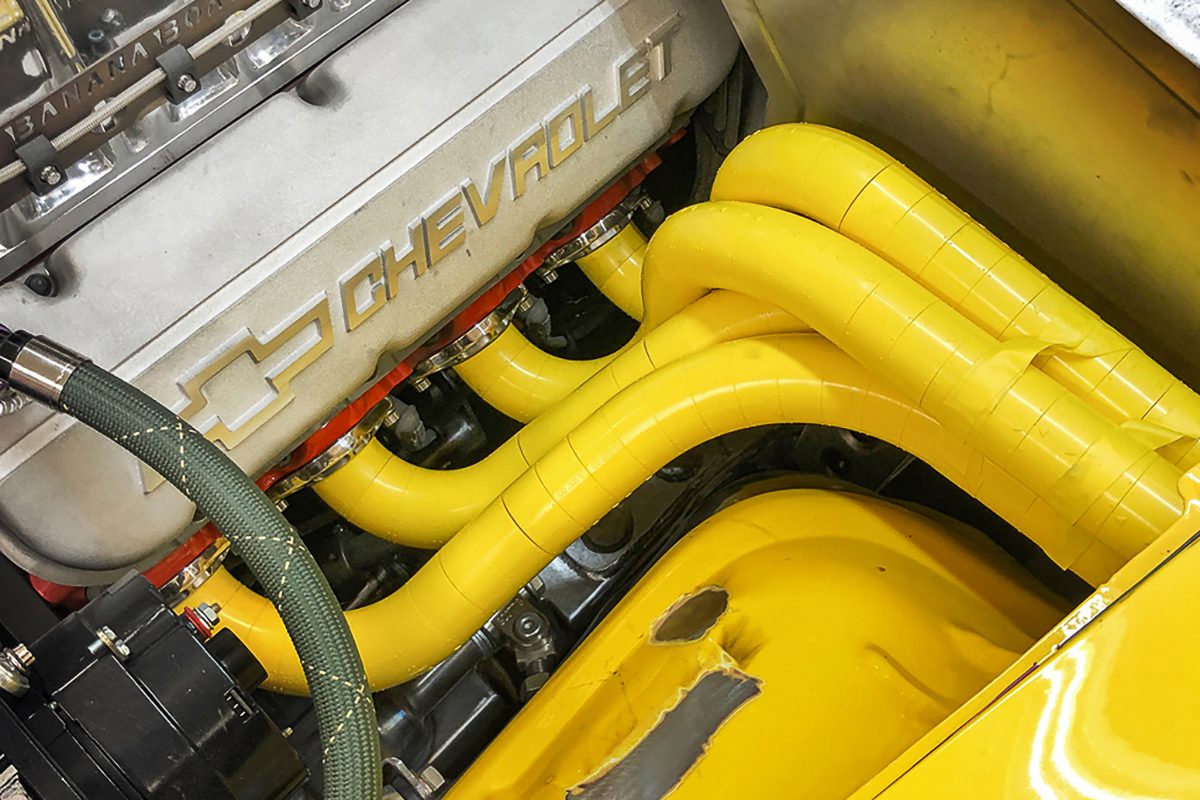

This header is an example of a finished piece built using Icengineworks modeling blocks. The blocks helped reduce the amount of time, effort, and trial-and-error work necessary to craft a complex design like this.

For more details on these and many other metal fabrication tools, head on over to the Trick-Tools website.

Photos courtesy Trick-Tools