Smooth Style and a Minty Green Finish Have Our Mouths Watering Over Bryan Battaglini’s ’69 K5 Blazer

You could argue that GM’s second-generation C/K trucks and Blazers are the ’32 Fords or ’55 Chevys for a different generation. GM made a zillion of ’em, they’re bulletproof, easily modified, and maybe the best-looking pickup truck ever made. Produced from 1967 to 1972, these “Action Line” trucks seem to gain more popularity as the years roll by.

Just like ’32 Fords, most every trick in the book has been exploited when modifying one of these trucks. What separates good C10/Blazer builds from great ones are attention to detail, tight assembly tolerances, and not straying too far from the original design.

Consider Bryan Battaglini’s ’69 Chevrolet K5 Blazer as Exhibit A of that aforementioned formula. He found a derelict Blazer, saved it from the boneyard in the sky, and then tenderly resuscitated it to the strapping beauty you see before you. Many of the latest trick components are present and accounted for, but it’s the combination of elements, plus Bryan’s keen eye for detail, that creates a sum greater than the parts. Let’s zoom in and get a closer look at the backstory on this old K5.

Bryan hails from Danville, California, is a husband, a father with three kids, and owns an electrical contracting company. He built the Blazer over a three-year period with the support of his family, friends, and some very talented craftsman in the NorCal area after finding the truck in forlorn and well-worn condition.

“It was a four-wheel drive K5 Blazer someone had torn down and left sitting in a field,” Bryan says. “I’ve been tinkering with cars since I was 16, but this sad old Blazer needed everything and was the first full-tilt build that I had undertaken.” Even though he has a restomod Camaro build and a C10 truck project under his belt, the K5 Blazer was a crash course in the realities of building a truck from the ground up, although you’d never know it by looking at the finished rig.

Bryan went with a Choppin’ Block Extreme Air Ride truck chassis as the foundation for the build, minus eight inches from the wheelbase to accommodate the K5. Ditching the ancient 4X4 frame was no-brainer and now the Blazer rolls on a state-of-the-art chassis that rides well and can easily lay frame. The suspension was equipped with air springs at all four corners direct from Choppin’ Block, and Bryan married them with to an AccuAir system to control the altitude. The unsprung components consist of Wilwood disc brakes (six-piston up front, four-piston in the rear) and 20×8.5- and 20×10-inch Bonspeed wheels wrapped in Nitto rubber sized 245/45/20 and 305/35/20, respectively.

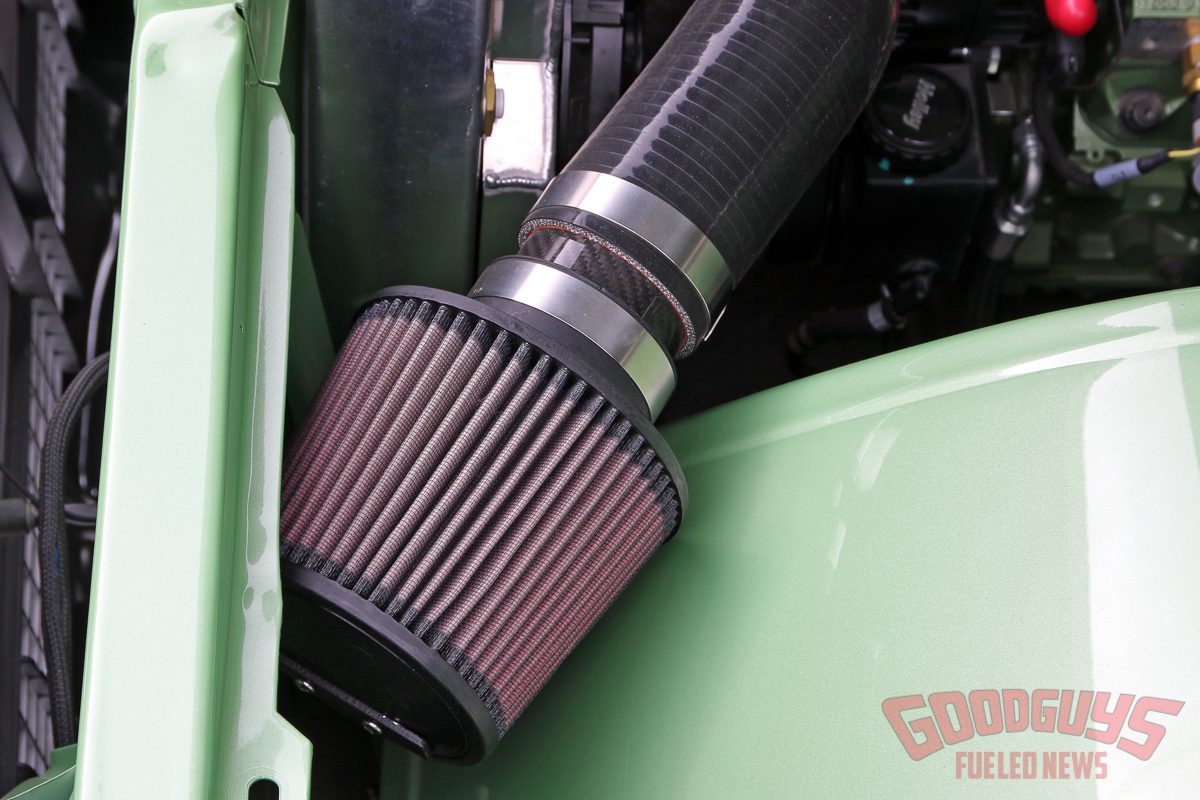

Under the hood, the Blazer is now LS1-powered and backed up by a 4L60E transmission. Producing a healthy 400 horsepower, the mill is running Hedman Headers, a Holley accessory drive, and a Mega Squirt EFI controller. The engine has been treated to an ebony finish and looks quite sinister under the key lime green hood. A Griffin radiator keeps things cool and collected, while the mighty LS expels exhaust through custom pipes with Lobak mufflers.

The bodywork and paint were handled by Marcos Auto Body in Sacramento, California, and the guys performed some tender-yet-effective exterior mods. They smoothed and massaged the top, the inner front fenders, firewall, and deleted all the emblems. Although the lime green color could easily be a stock GM hue from back when Richard Nixon was president, it’s actually a tweaked version of PPG’s Frost Green, with some pearly effervescence mixed in for good measure. Danny at A&H Customs handled the mixology.

Inside, Bryan commissioned AJ at Modesto Customs to stich up the seats and door cards with tartan plaid fabric inserts ‘a la Volkswagen GTI. The cabin sports a leather-wrapped dash, Dakota Digital gauges, Coach Control wiring, and a Vintage Air system. With the green dash and the tobacco brown seats, the interior kind of reminds us of those five-cent Crème de Menthe candies that you buy at the restaurant check out. Delicious!

After the rig was complete and making the rounds at car shows, Bryan reflects on the k5 Blazer build and the lessons learned. “A project like this is a huge expenditure of time, money, and patience,” he says. “When I go to car shows now, I appreciate the builds so much more. I had a lot of help putting this car together, so I’d like to say thanks to Danny at A&H Customs, Kim and Matt at Matt’s Classics, Hill’s Rod and Custom, Steve Walesky, Neil Ruegsegger, Marcos Auto Body, and Modesto Customs. Most of all, I’d like to thank my family for putting up with me and my car-building obsession.”

Well said, Bryan. Well said.

Photos by Steven Bunker