A Refresher on Brake System Fundamentals

With the pursuit of designing and building hot rods that have the capability to perform and handle like modern sports cars, there have been huge strides from the performance aftermarket in product development. Many of these innovative components are drivetrain based to adapt late-model engines and overdrive transmissions into our classic cars, while there’s no denying the uptick in advanced suspension and handling parts, too.

One important aspect of handling and driving enjoyment comes through the braking capabilities of a vehicle. Consistent, smooth braking is imperative to any vehicle whether it’s used to cruise the family out for an ice cream or if you’re speeding down a straight into a hairpin. And like modern day drivetrains, adjustable coil-overs, and direct port injection, there have been great strides over the past years in brake systems and components designed for vintage cars and trucks.

Years ago, braking performance was almost considered an afterthought in the hot rodding world, but today brakes are very much front and center, especially in the world of pro-touring and AutoCross-focused builds. Cross-drilled rotors and billet calipers fill the space behind 19-inch wheels, adding not only cool looks, but incredible stopping prowess.

Today, the importance of a solid pedal feel and consistent braking cannot be understated, whether you’re building a 700-horsepower g-machine or a vintage sedan for cruising. Whether you’re running a disc/drum combination or six-piston calipers, there are still a number of things to consider when it comes to planning and putting together a secure, safe brake system. We figured the winter months were a perfect time to go over a few braking fundamentals and the behind-the-scenes components.

Hydraulics and Brake Fluid

The brake system is basically a mini hydraulic network with plumbing from each wheel running up to a common point, the master cylinder. The brake pedal uses mechanical leverage to exert force onto a pushrod and piston inside the master cylinder to pressurize the fluid in the lines. This pressure pushes against the pistons of the calipers or wheel cylinders, which in turn force the pads to squeeze the rotor, or in the case of drums, push the shoes out into the drum surface to slow the car.

Red Line Oil offers their RL-600 brake fluid which is rated at DOT 4 standards. It is recommended for high-performance use in street or racing applications and works to prevent brake fade under extreme use. As a side note, always start with a fresh can of brake fluid. An open canister that has been on the shelf a while will absorb moisture.

The small piston within the master cylinder is capable of moving a larger piston (like in the caliper) with more force albeit a shorter distance (think of a floor jack and how big of a stroke you take on the handle to move the lifting mechanism). It’s all physics but the takeaway is that you need to carefully select the master cylinder to match your application as the bore (along with the pedal ratio) will affect the pedal feel and braking performance. We’ll get into that a little more soon, but first let’s look at brake fluid.

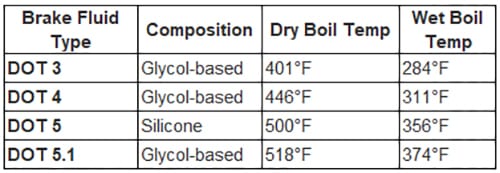

The fluid used in a brake system undergoes tremendous pressure and heat cycles. Like engine oils, there are several different grades of brake fluid to choose from to match your goals and driving conditions. The most common fluids are specified by the Department of Transportation as DOT 3, DOT 4 and DOT 5.

The fluid used in a brake system undergoes tremendous pressure and heat cycles. Like engine oils, there are several different grades of brake fluid to choose from to match your goals and driving conditions. The most common fluids are specified by the Department of Transportation as DOT 3, DOT 4 and DOT 5.

DOT 3 is the base fluid and is not as capable of performing in higher performance applications compared to the DOT 4 blend. DOT 5 is a silicone-based fluid which while not designed for high performance driving is a favorite to hot rodders as it will not remove paint if it gets spilled or splashed compared to DOT 3 and 4, which are highly corrosive to paints and coatings.

Brake fluid must hold its operating parameters through quite a few different requirements. It must have a low freezing point as well as an extreme boiling point. During these varied operating parameters, the fluid must have a constant viscosity and maintain its compressibility. Add to the list its ability to lubricate the moving components and prevent corrosion, it makes for a pretty tall order.

It is important to note that mixing DOT 3 and DOT 4 fluids is acceptable, however never mix a DOT 5 synthetic fluid with DOT 3 or 4 fluids. Component deterioration as well as the transfer of pressure will not function as well when combined. To confuse things a little more, there is also a DOT 5.1, which can be mixed with DOT 3 and 4, but NOT DOT 5! Ask your brake manufacturer for their recommendation and it’s likely they have their own brand already on hand.

Brake Pedal and Assembly

Wilwood offers a variety of pedal assemblies and this one is built with a clutch pedal and allows the master cylinders (hydraulic clutch, too) to be mounted inside the firewall.

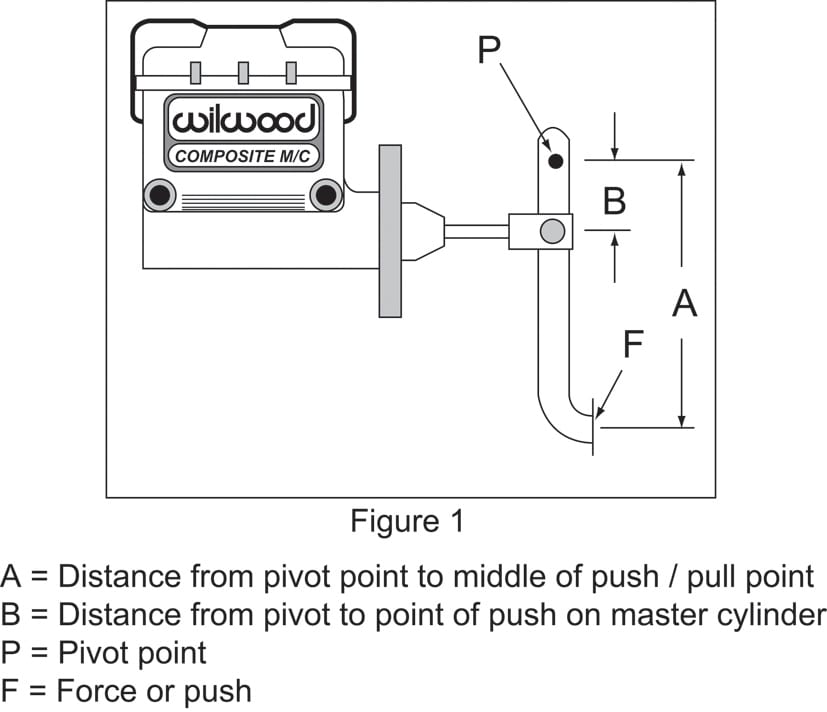

Since the braking process begins with your foot pressing on the brake pedal, it’s a fitting topic to review. The pedal assembly acts as a simple lever to force the pushrod into the master cylinder to pressurize the brake system. The position and length of the pedal lever and its pivot point have an effect on how much force is supplied to the master cylinder, and how much force is required.

You may use the factory pedal setup, but for serious braking performance there are many aftermarket assemblies available that mount to the floor or the firewall and have adjustments to position each  pedal exactly to fit your needs. Aftermarket pedals are designed to accept remote master cylinders or even dual units (one for the front, one for the rear) which provide increased adjustments for pedal feel and braking bias between the front and the rear.

pedal exactly to fit your needs. Aftermarket pedals are designed to accept remote master cylinders or even dual units (one for the front, one for the rear) which provide increased adjustments for pedal feel and braking bias between the front and the rear.

Knowing the pedal ratio (mechanical leverage) of the brake lever will allow you to adjust the amount of force required to activate the brakes. To come up with the pedal ratio you’ll need to measure the distance from the pivot point of the brake lever to the middle of the pedal push point and divide it by the distance from the pivot point to the pushrod connection. By adjusting the lengths, you can increase/decrease the brake force without increasing the pedal feel/effort.

Master Cylinder

The master cylinder is one of the most important components of your brake system and plays a direct role in the resulting pedal effort, modulation, and the overall braking effectiveness of the system. When selecting a master cylinder, it is highly advised to use the recommendation of the brake system manufacturer due to the number of variables in caliper, booster, or drum designs and fitments.

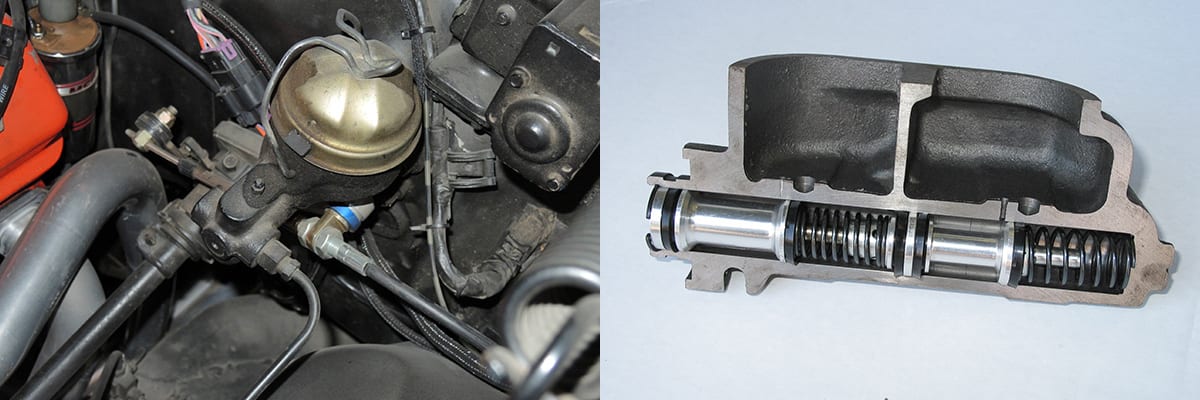

The master cylinder is the heart of the system brake system. It has a reservoir to hold the brake fluid and it converts the mechanical effort from the brake pedal into hydraulic pressure to activate the brake calipers and/or drums. Within the cylinder bore, there are small ports that direct the fluid to the proper brake circuit (front or rear).

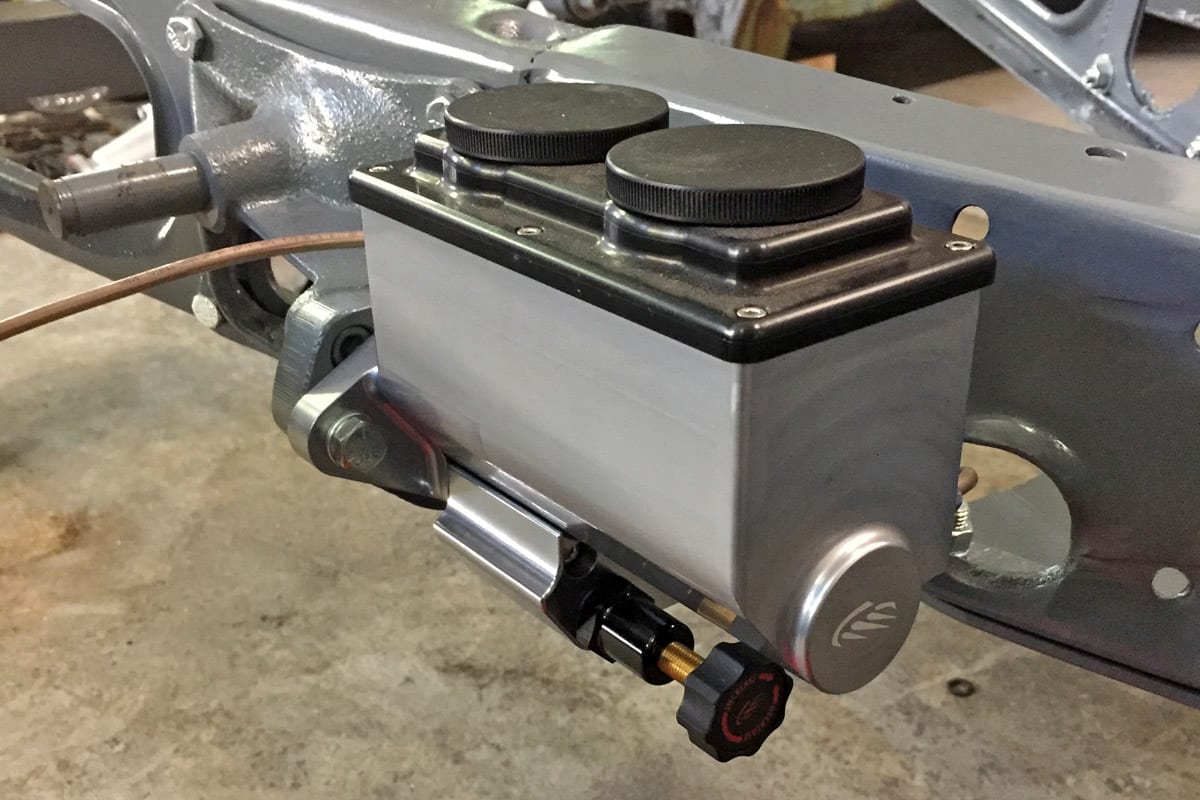

It’s a standard practice to mount the master cylinder to the chassis like this example on a ’40 Ford. This is Baer’s Remaster master cylinder. Note the proportioning valve designed to fit right under the assembly.

Many older vehicles were equipped with a single channel master cylinder which should be one of the first items you update on any classic that you plan to drive. The reason is simple: safety. A single reservoir is responsible for maintaining both the front and rear brake circuits and if one circuit is compromised, it affects the operation of the other. A dual master cylinder splits the front and the rear circuits so if one system were to have a failure, there would still be braking function from the other.

There is nothing good about a single line master cylinder. If there is a leak in one of the four wheel cylinders or damage to a line occurs, the vehicle’s overall braking capabilities will be lessened. A dual-circuit cylinder – shown in the cutaway image here – separates the fluid activating the front and rear brakes, so if one portion of the system fails or has a problem, the other will continue to work. Do yourself a favor and step up to a dual-circuit master cylinder if you haven’t already.

There’s more to selecting a master cylinder than you might think. There are different bore sizes available; a larger bore will create more fluid displacement but will require more pedal force while a smaller bore will produce more pressure. You’ll need to determine whether you plan to run power assist or stick with manual brakes. There is no one guideline when selecting a master cylinder, as there are other variables in the system including the calipers being used, weight of the vehicle, even seat position. It is highly recommended to use components from a single source since manufacturers design and engineer their products to work together. Go ahead and give them a call or chat with a tech at one of our shows to get their expertise!

Power Assist

In the brake system world, you’ll have either manual brakes or power assisted brakes. Manual brakes will have a harder, definitely firm pedal feel because you’re dealing strictly with the hydraulics, pedal geometry, mechanical contact, and forces within the brake system. Adding power assist provides a much easier and consistent pedal feel to achieve the same result. Remember, disc brake systems can require approximately 900-1,200psi to function as designed, so having a little assist can be a nice feature.

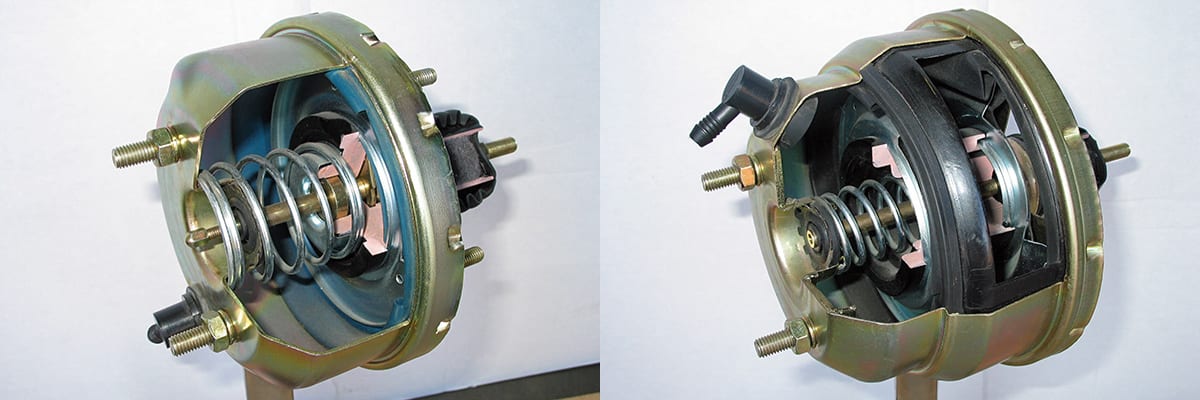

The most common way to add power assist to the brake system is through a vacuum operated booster. Vacuum boosters are available in a number of diameters and sizes to fit different applications.

There are two main ways to achieve power brake assist; with vacuum or through hydraulics. (There are also electric vacuum motors available.) The most common practice is the use of a vacuum-operated booster, which is the large, round assembly positioned between the master cylinder and the firewall.

Vacuum boosters are available in single- and dual-diaphragm designs, as illustrated by these cutaway photos. Dual-diaphragm boosters use an extra vacuum diaphragm to increase power assist in a smaller-diameter booster assembly.

The vacuum booster uses engine vacuum and atmospheric pressure to assist the pushrod movement into the master cylinder. Typically, an engine needs to be able to create a minimum of 16-inches of vacuum and you’ll need to consider space under the hood to fit the booster. Smaller boosters may fit better, but they require a stronger vacuum signal from the engine compared to their larger diameter counterparts. If space is a premium or your engine has a rowdy cam, a hydraulic brake assist system can be considered.

An alternative to a vacuum power assist is achieved by plumbing into the power steering system and incorporating the assist from hydraulic pressure. CPP offers their HydraStop system that will effectively provide the assist you want if you don’t have room for a vacuum booster or the engine doesn’t make enough vacuum.

A hydraulic brake assist system, commonly referred to as hydroboost, is used in conjunction with the power steering pump to produce assist through hydraulics. This style of brake assist was originally used on vehicles with diesel engines and more recently on a number of LS-powered vehicles. They have found their way into the hot rod world to replace large vacuum booster assemblies. The assembly looks like an extension of the master cylinder and mounts in place of the booster. This is a terrific option for high-horsepower engines or to simply clear your engine compartment of an unsightly vacuum booster.

Brake Valves

An adjustable proportioning valve, such as this one from Baer, mounts inline on the rear brake circuit allowing the user to fine tune the pressure rise to the rear brakes.

Depending on the application, there are several different accessory valves that mount inline of the brake plumbing to ensure the best operation and application of the front and rear brakes. Some of these components are similar in their operation, with the goal of controlling the pressure and when it activates the different brake circuits.

A proportioning valve is used with disc or drum systems and is primarily installed inline on the rear brake line circuit. Its goal is to control or limit the rate of pressure increase at the rear wheels. By limiting, or at least slowing the pressure rise, the valve will prevent the rear wheels from locking up under hard braking to compensate for weight transfer. There are many adjustable proportioning valves available that allow you to fine-tune the bias to suit your application.

A metering valve is required with disc/drum combinations to activate the rear brakes moments prior to the front. This helps control the bias between the front and rear.

A metering valve is used on vehicles with front discs and rear drums and is tasked with equalizing the pressure between the front and rear. In theory, the rear brakes should be energized before the front discs to prevent the car from dipping excessively in the front or locking up the front wheels first. The OEMs also used a combination valve, which is designed for a specific brake system, weight and vehicle size. For hot rods and custom applications, using a separate proportioning valve is often the better choice.

In early hot rods, it’s common practice to mount the master cylinder under the driver’s floor on the chassis. However, when the master cylinder is located lower than brake calipers or wheel cylinders, you need to install a residual valve in the brake lines.

If the master cylinder is mounted below the height of the caliper or wheel cylinders, a residual valve should be installed inline to prevent the fluid from syphoning down and to the master cylinder. Discs require a 2psi valve, while a 10psi valve is used for drums.

The residual valve is a small inline device that prevents the fluid from the calipers and higher lines from siphoning back down into the master cylinder. There are typically two different residual valves; a 2psi version and a 10psi unit.

For a disc brake circuit, the 2psi valve is used and will keep the fluid from draining back to the master cylinder. It will also maintain pressure in the brake line to prevent excessive pedal travel or having to pump the pedal a couple times to have full braking capabilities.

A 10psi valve is required on drum brake setups, unless the master cylinder already has one built in. The valve will also protect the hydraulic system from air weeping in through the wheel cylinder seals and like the smaller pressure valve, it will help keep pressure in the circuit to prevent a spongy feeling brake pedal.

Brake Light Switches

A brake light switch will be needed in any brake system to operate the brake lights. In most cases, you can retain the spring-loaded switch that is mounted under the dash and to the pedal assembly. For custom set ups, there are also hydraulically operated switches that activate the brake light circuit when pressure is sensed. These can easily be installed inline on the rear brake line with a junction block.

A compact a hydraulic switch is common to activate the brake light circuit. When the switch senses a small rise in pressure, the contacts are closed to activate the brake lights.

Sources

Baer | CPP | Master Power Brakes | Wilwood