The Fundamentals of EFI – Advice and Products for Preparing Your Car for Electronic Fuel Injection

Trends in hot rodding come and go, but one upgrade that shows no signs of slowing down is swapping to Electronic Fuel Injection. EFI swaps have been around for quite a few years now, dating back to the ’80s with TPI engine swaps and the mid-’90s on the drag strip with racers taking advantage of precise control over the fuel and timing. This technology helped with the adaptation of forced induction systems and today it’s commonplace to see laptops in the pits for slight tuning adjustments.

For hot rods and street-based muscle cars, race EFI technology has trickled down and combined with late model OEM advances to become a favorite upgrade with good reason. Electronic Fuel Injection delivers excellent cold starts, smooth idle and throttle response, adapts to altitude and different driving conditions, and in general delivers overall drivability improvements. And thanks to an ever-innovative aftermarket, the EFI systems available continue to evolve, are easier than ever to install and use, and fit more applications than ever.

There are EFI systems for nearly anything ranging from 2-barrel systems for lower horsepower cruisers to multi-throttle body systems for classic hot rod looks, clean multi-port manifolds and even trick eight-stack systems to make a modern engine have the look of a vintage race engine. It’s all there and best of all is that the systems are easier than ever to install and tune.

There are EFI systems for nearly anything ranging from 2-barrel systems for lower horsepower cruisers to multi-throttle body systems for classic hot rod looks, clean multi-port manifolds and even trick eight-stack systems to make a modern engine have the look of a vintage race engine. It’s all there and best of all is that the systems are easier than ever to install and tune.

Swapping to EFI has become increasingly easier and most street systems can be programmed through a handheld monitor so there’s no laptop tuning required. No matter what EFI system you choose, there are several common areas that you need to prepare and prep for, such as the fuel system, exhaust, and of course, wiring.

We gathered some of the latest Electronic Fuel Injection systems as well as a number of accessories that you’ll need to consider when upgrading to electronic fuel injection. There’s no better time than right now to make the EFI upgrade; it’s a perfect winter project because when spring rolls around, you’ll be ready to hit the road with modern technology fueling the way.

Howell EFI

Howell EFI

OE EFI for Hot Rods

The OEMs have invested thousands of hours into the research and development of their EFI systems, so it certainly makes sense to take advantage that proven performance. Since 1988, Howell EFI has engineered OE-quality GM-based EFI systems for hot rods and 4WD applications, including a large selection of Jeep TBI kits, GM tuned port or multi-port EFI systems, and LSX/Vortec, LTX/Ecotec3 harnesses. They recently added Ford and Mopar to their lineup with TBI kits for popular Chrysler V8 engines and many Ford TBI conversion kits.

All Howell TBI kits feature a remanufactured GM throttle body appropriate for the engine size, all sensors (MAP, coolant, and O2), a stand-alone wiring harness, ECM, fuel pump, and one of three sized adapter plates. The Howell TBI kit also allows for a custom calibration PROM for the engine and an ECM that installs under the dash, so no tuning is required, and each kit utilizes the OBDI GM diagnostic capabilities for scanning codes.

Edelbrock

Edelbrock

Pro-Flo Fuel Flow

The latest EFI system from Edelbrock is their plug-and-play Pro-Flo 4+ engine management system for Gen III/IV GM LS, Gen I and II Coyote, and Gen III Hemi engines. The ECU uses a sophisticated self-learning technology combined with base calibrations to deliver out-of-the-box performance to get you on the road, while a handy wizard setup guides you through the initial calibration with ease. An app, E-Tuner 4+, can be downloaded for free from the App Store or Google Play, which gives you complete control of the system.

This is the most simplified engine management system for modern engine swaps. It can be used with two Drive-by-Wire throttle bodies, controls four variable cams, uses dual WBO2 sensors, knock sensors, and more to ensure your classic ride runs as good, if not better, than a modern muscle machine.

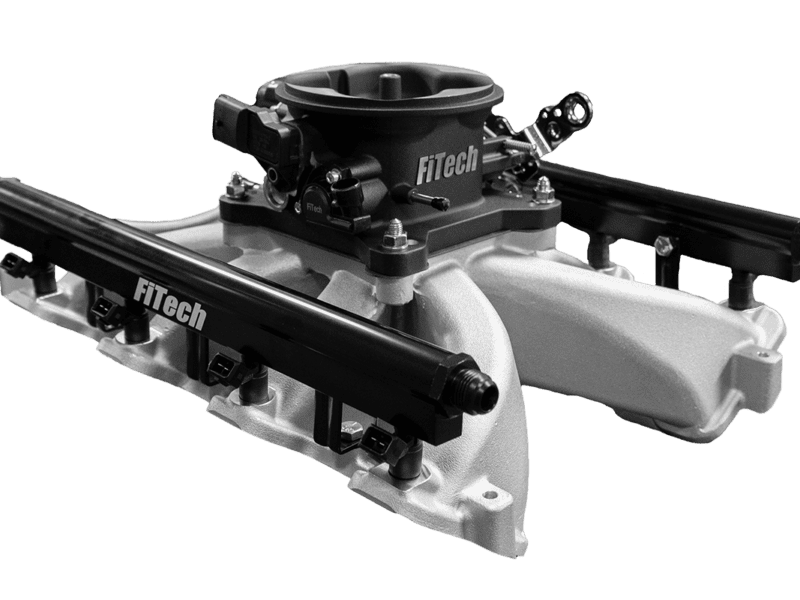

FiTech

FiTech

All in One

Confidence in starting a cold engine and crisp throttle response are some the top benefits of fuel injection over a carburetor. FiTech EFI understands that it takes more than just a throttle body or port fuel system to create a reliable, good-performing EFI system. The entire system, including fuel delivery and electrical, must be up to the task.

The need for consistent fuel pressure from the fuel delivery system is vital for reliability. FiTech has designed a number of products such as the Force Fuel sump system, Go Fuel In-Tank Pump Modules, and complete tank conversions with internal pumps that all provide reliable and consistent fuel pressure for the EFI system. Pairing a properly selected fuel delivery system with an EFI system will result in the best drivability, performance, and reliability possible.

Fueling Nostalgia

Many enthusiasts steer clear of stepping up to EFI simply due to the modern appearance of the systems. However, thanks to several clever and innovatie companies, there are fuel injection systems designed with vintage flavor and flair and in some cases, only the sharpest eye will determine if there’s a computer controlling the fuel delivery. Check out these three examples.

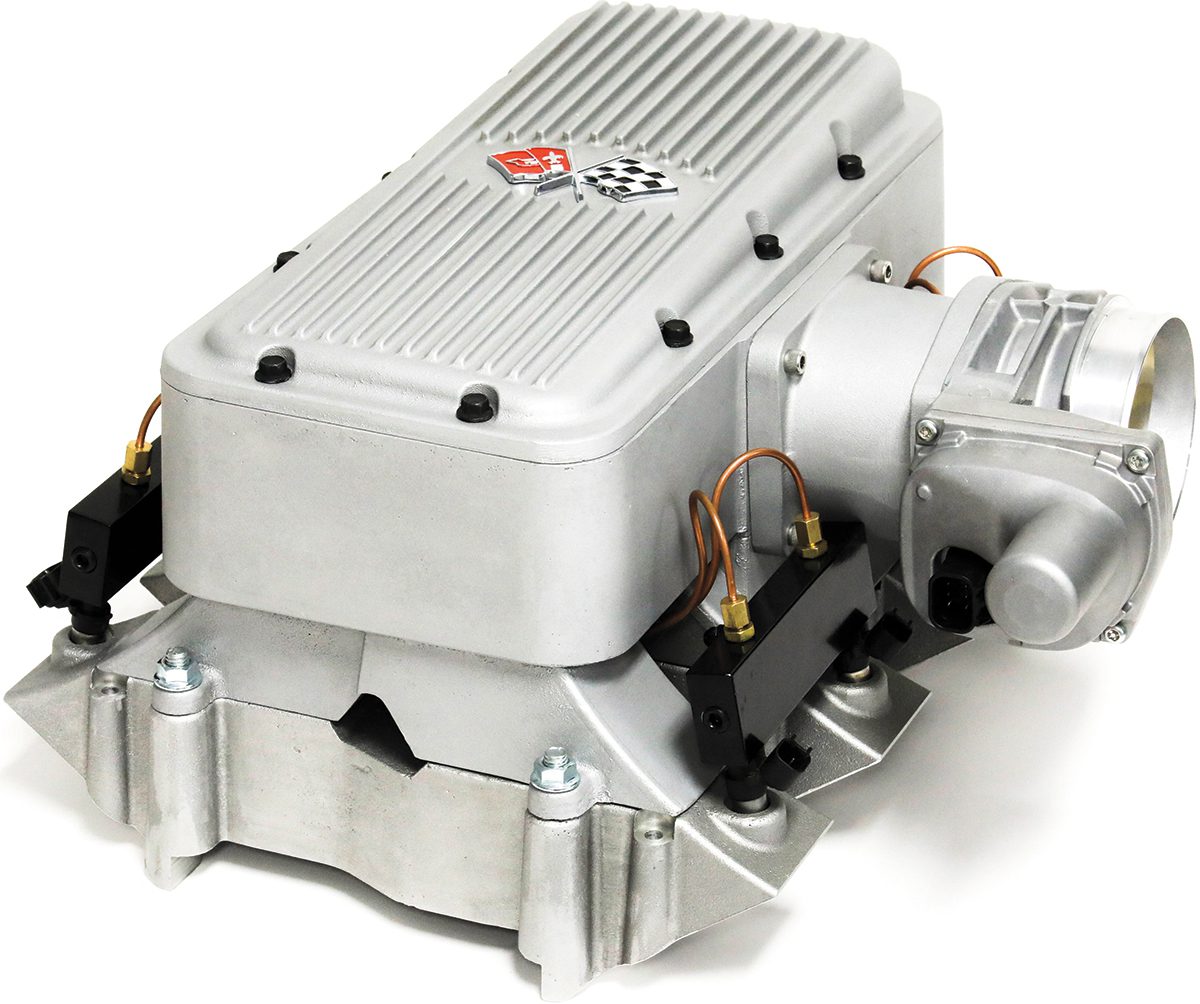

LS Classic by Lokar

LS Classic by Lokar

Modern Fuelie

You can praise its compact design, performance, and reliability, but the GM LS platform has never been known for its great looks from the factory. Thankfully there are many cool valve cover kits, covers, and intakes to dress up the LS, but the team at LS Classics has taken things to another level with offerings like their ’63 Fuelie intake setup.

The Fuelie intake is a cast aluminum, two-piece manifold just like GM’s second-generation mechanical injection systems that were installed on ’63–’65 Corvettes. The systems utilize GM LS3 OEM fuel injectors and a GM four-bolt, 92mm Drive-by-Wire throttle body (not included) and are compatible with GM and aftermarket ECUs and harnesses that support both drive-by-wire and speed density tuning. The kits are designed to work with rectangle and cathedral-port LS cylinder heads.

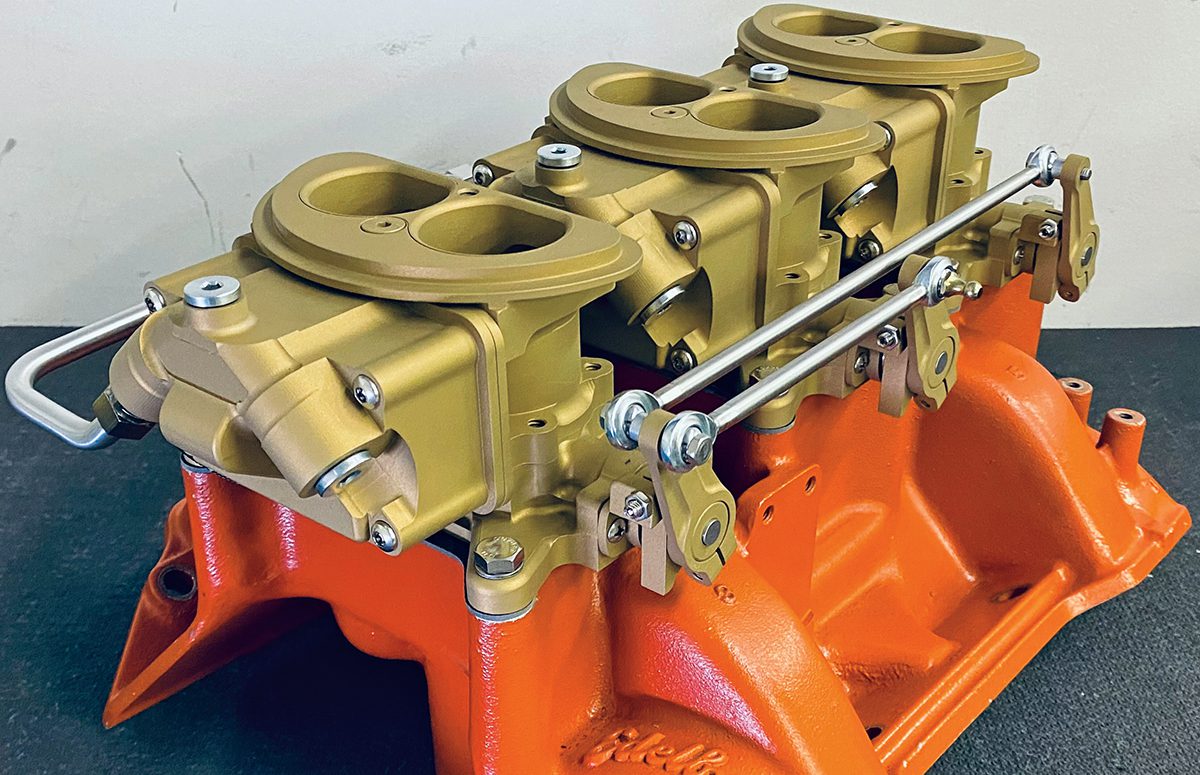

Autotrend EFI

Autotrend EFI

Nostalgic EFI

What does a hot rodder do when you crave the classic look of a three deuce setup, but wantsthe drivability of EFI? They dial up Autotrend EFI to order up their new EFI-6PAC setup.

Autotrend has developed a throttle body with the appearance of a vintage Holley 2-barrel carb that is perfect for a Mopar Six Pack, Corvette tri-power, or a nostalgic hot rod. Each throttle body is machined from billet aluminum and flows 500cfm. Systems come complete with Holley EFI management systems and will be remote tuned by the experts at Autotrend EFI. They also offer similar throttle bodies based on the 2G Rochester and the Stromberg 48.

Borla Induction

Borla Induction

Modern Vintage

If you’re a fan of vintage Weber-style induction systems but crave the modern drivability of EFI, be sure to check out Borla Induction. Yes, the same company that manufacturers trick exhaust systems also offers a multitude of equally trick EFI setups, including complete eight-stack systems.

Some of Borla’s setups have a full-on stealthy appearance with hidden injectors that leave most people wondering if they are in fact real Weber carbs. Borla uses high-quality 356 castings and billet paired with OEM fuel injectors, throttle position, and MAP sensors to build custom fuel injection setups for popular Ford and Chevy engines, including modern LS and Coyote platforms. You can choose from powder coat, paint, polish, or classic gold Cerakote finishes, and each intake setup is fully assembled, synchronized and ready to bolt on.

Fuel System Prep

The most important modifications needed to support your new EFI system are going to be with the fuel system. Every EFI system requires consistent, higher fuel pressure. The required pressure varies with the system, but 58psi is average for many popular systems. This means you’ll need a high-pressure electric fuel pump, hoses, quality fittings, and a filter that can handle the high pressure.

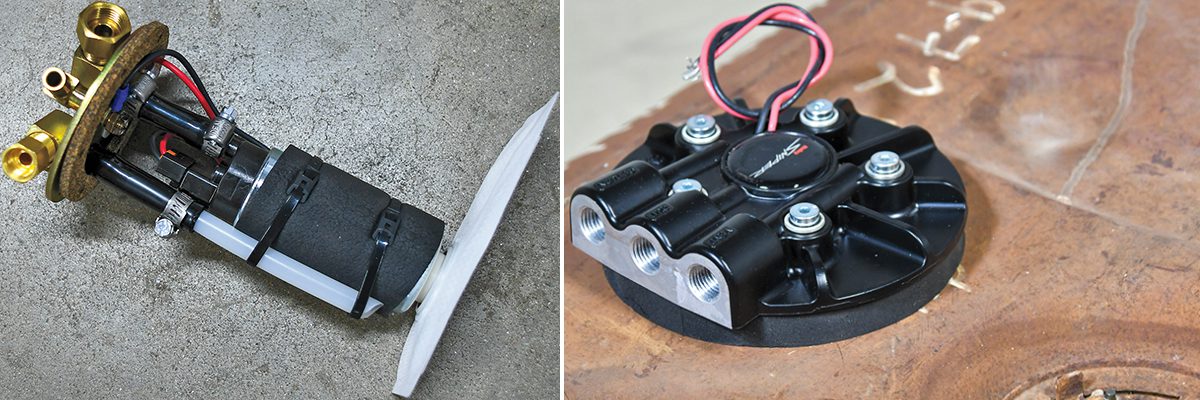

When it comes to mounting an electric pump, the best place is to have it in the tank. There are several reasons for an in-tank pump: The pump runs cooler when it’s submerged in fuel, there is much less pump noise, and since electric pumps are made to push fuel, not pull it, the tank is the best place to ensure long life and operation.

You can mount an electric fuel pump in your original tank with a universal pump module. These examples from Tanks Inc. and Holley allow you to set the depth of the pump pickup and have an outlet, return, and vent along with electrical connections.

Many manufacturers offer bolt-in tanks or even fuel cells that are designed to accept an electric fuel pump. Most of these tanks also have internal baffling so the pump intake is always surrounded by fuel to prevent starvation around corners or acceleration. If a new tank is not available for your application, there are also universal pump modules available that allow you to modify your existing tank and mount a pump. If these solutions still don’t fit your application, there are several companies that build custom tanks which would be worth looking into as well.

Classic Performance Products (CPP)

Classic Performance Products (CPP)

Pro-Touring Aluminum Fuel Tank

Planning to zip around the cones and carve some canyon corners in your classic Chevy? CPP now offers a Pro-Touring Fuel Tank for popular Chevy muscle cars that is designed to support the fuel requirements of fuel injected (or carbureted) engines while still being mounted in the factory location.

These tanks feature an integrated surge tank designed to keep the fuel pickup submerged at all times. The tank has provisions for two pumps for high g-force applications or can be used with one pump for moderate street use. When utilizing dual pumps, one acts as a lift pump to keep the surge tank filled preventing the fuel system from drawing in air during hard acceleration, braking, and cornering. CPP’s Pro-Touring tanks are currently available for ’62-’67 Novas, with applications for ’67-’69 Camaros and ’64–’72 Chevelles coming soon.

Summit Racing Equipment

Summit Racing Equipment

EFI Racing Cells

Working on a racing or custom setup that requires a fuel cell? Summit Racing can help you with the fuel delivery demands of an EFI system thanks to their new EFI Fuel Cells. These lightweight 5052 aluminum fuel cells are available in 12-, 15- or 20-gallon capacities and are TIG welded and ready to bolt in.

The tanks are fully baffled internally to prevent any fuel starvation and fitted with a durable 255 LHP electric fuel pump that is ready to be wired. A 0-90-ohm sending unit is installed to supply a fuel level gauge and the system is set up with a ¼-inch NPT feed and return line to support any EFI system.

TANKS Inc.

TANKS Inc.

EFI Tanks

If you’re updating a ’63-’72 Chevy or GMC pickup, do yourself a favor and move the tank out of the cab and under the bed with a new EFI-ready, frame-mount tank from Tanks, Inc. The tank is designed to bolt up to the bottom side of the frame rails, but it can be mounted in different configurations including on top or even in-between the rails in some cases.

These tanks are EFI ready with internal baffling through an extra-large 4.8-liter dual tube baffled fuel tray to prevent fuel pump starvation. Tanks offers fuel pumps from 109-450 LPH and provides the internal pump module and five-bolt sender for stock or aftermarket gauges. Each tank is die stamped from galvanized steel and powder coated silver. The C10 tank holds 18 gallons and Tanks offers a long list of other applications for classic cars and trucks.

It should come as no surprise that with the higher fuel pressure required of EFI, you’ll need to plan to run new fuel lines. This is no place to skimp, and the hose must be rated for high pressure as well as rated for today’s fuel blends. Also note that you’ll be running a feed line as well as a return line that circles back to the tank. Some EFI systems are equipped to run as a returnless system but most of the installers we talked to recommend to just plan on plumbing a return system. Also, don’t forget a fuel filter! EFI systems need clean, debris-free fuel and a high-pressure filter is required to trap any injector-clogging materials.

An alternative to an in-tank pump is to mount a fuel sump system. This example is the Force Fuel from FiTech. It relies on the original mechanical pump to fill a reservoir that has an electric pump in it to feed the fuel injection.

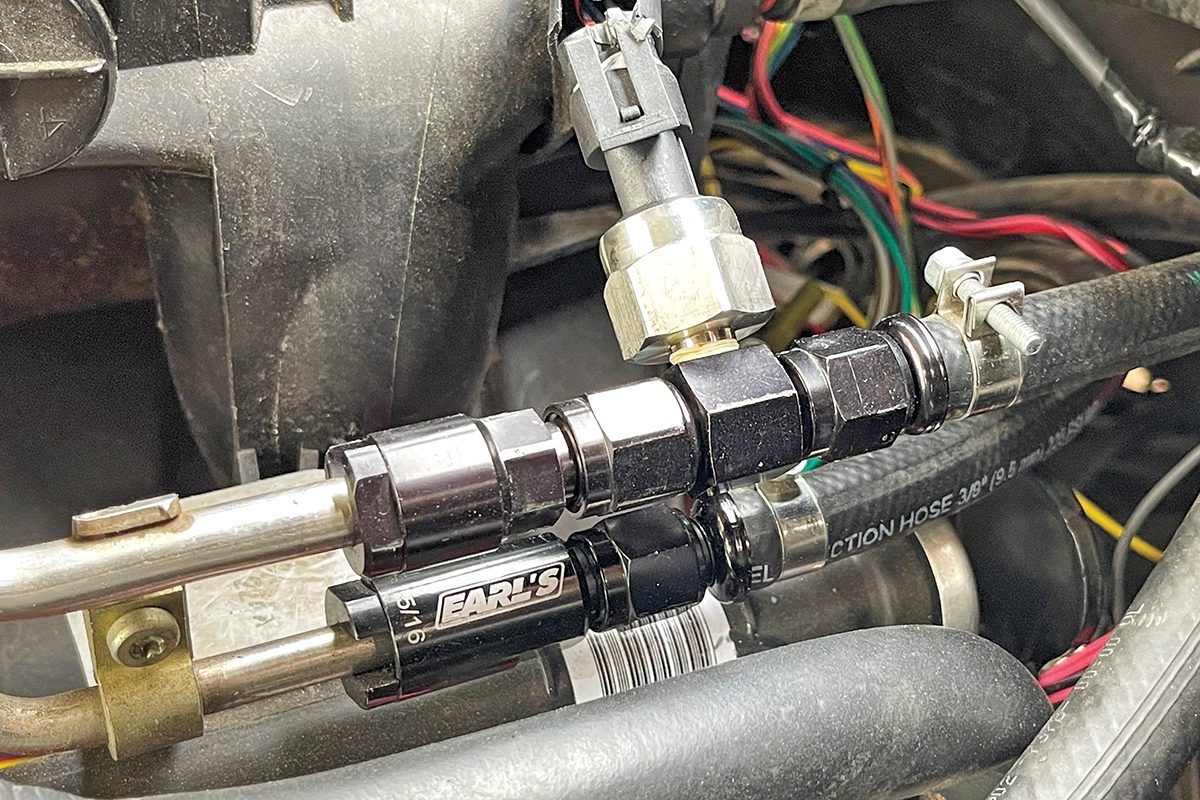

Speedway Motors

Speedway Motors

Return Filter

Three things are required with any EFI fuel system: a fuel filter, a regulator, and a return line. Speedway Motors offers this trick LS V8 Fuel Filter/Regulator Kit fuel filter that answers all of these needs and eases the plumbing of the entire fuel system.

The kit, PN 91012800, is based on a canister-style filter assembly that has a 3/8-inch inlet and outlet to fuel the engine as well as a 5/16-inch return port that routes fuel back to the tank, effectively creating a return style fuel system. There is also a fixed pressure regulator that puts the fuel pressure at 58psi, which is ideal for LS engines and many aftermarket EFI systems. The 5-micron filter ensures only clean fuel reaches the injectors and Speedway also supplies adapters to convert to -6 AN lines and fittings.

It’s not just the hoses and lines that need to handle high pressure, the fittings and clamps must also be updated. Most manufacturers supply or recommend push-lock or AN-style fittings but there may be other adapters such as AN-to-OEM fuel rails or other 3/8-inch hose to -6AN fittings. Planning ahead and thinking things through will save you time, as there’s nothing worse than being one fitting short of starting the engine! Unless you have easy access to fittings, clamps and hoses, do yourself a favor and source a complete fuel line kit when purchasing the EFI system.

- If you’re using the OEM fuel lines on the intake, you’ll need an adapter to connect the fuel delivery (and return) lines. These Earl’s adapters are made for a quick connection with the feed fitting and also have a port to connect a fuel pressure sensor.

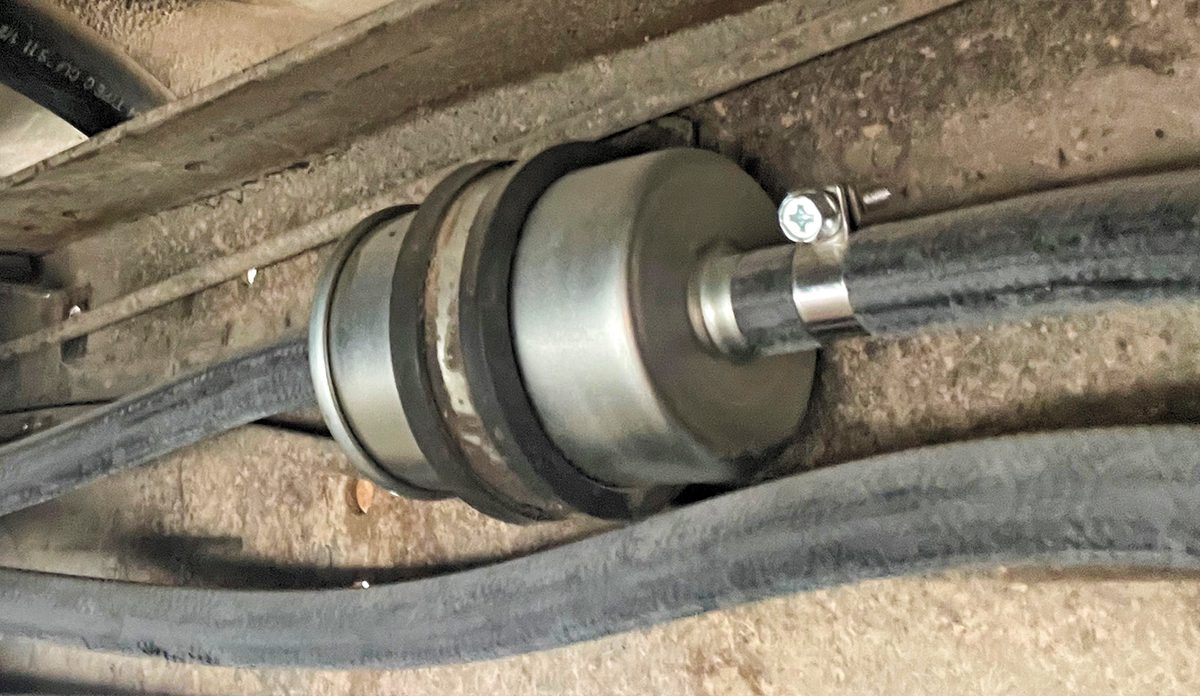

- An inline fuel filter is required between the pump and the injectors. Filters come in a variety of sizes and with inlet/outlets, so be prepared if you need AN fittings or high-pressure hose clamps. Also, remember that the filter is a maintenance item, so keep it accessible.

- Some EFI systems have a built-in regulator while others may require an external regulator. Make sure to check with the EFI manufacturer before starting your installation!

SENSORS

An electronic fuel injection system depends on the constant feedback of several important sensors including coolant temperature, manifold pressure (MAP), throttle position (TPS), and an oxygen sensor (O2) that is placed in the exhaust. Many throttle body systems have the TPS and MAP built-in and other systems may require an Intake Air Temp (IAT), Mass Air Flow (MAF), but the two sensors you can always count on installing are the coolant temp and the O2 sensor.

The O2 sensor must be installed in the header collector or down pipe from an exhaust manifold where it constantly senses the amount of oxygen in the exhaust. This in turn tells the ECU if the engine air/fuel mixture is rich (too much fuel) or lean (too little fuel) so it can correct the delivery to achieve the target air/fuel ratio.

The oxygen sensor should be mounted 6-10-inches after the collector (or where all the cylinders merge) and there should be 18-24-inches of pipe after the sensor. Always mount it on the top area of the pipe to prevent condensation from collecting on the sensor.

When installing the O2 sensor, it’s best to have the bung welded in place so it is sealed tightly. Follow the manufacturer’s guide to placement in the system and make sure there are no leaks in front of the sensor. Any manifold or header gasket leak will affect the O2 reading, resulting in throwing off your entire calibration and performance. In this case, the ECU will be told there’s a lean condition and try to compensate by adding fuel, resulting in an overly rich fuel mixture and poor drivability.

If you’re not equipped to weld in your garage, it is recommended to drive down to a muffler shop that can handle welding a O2 sensor bung in place before you start the installation (a plug is usually supplied by the manufacturer). An alternative is a clamp-in O2 sensor assembly that wraps around the pipe and is secured with heavy duty hose clamps. For the long run, welding is the best.

As for the coolant temp sensor, it shouldn’t be difficult to find a port on the heads or intake manifold, but it depends on the engine. If your engine only has one port which is used for the dash indicator, you’ll have to figure out an alternative. Also, do you have a sensor in place for an electric fan control? Just a couple things to consider when it comes installing to the coolant temperature sensor.

Dakota Digital

Dakota Digital

Sharing Data

If you’ve stepped up to an EFI system in your classic, Dakota Digital offers an extensive line of universal and direct-fit gauge packages that can easily be connected through the EFI’s ECU thanks to their BIM-01-2 OBD-II/CAN Interface device.

The BIM simply plugs into the diagnostic port of the EFI system and pulls data such as the speed, tach, temperature, oil pressure and gear position right from the ECU and sends it straight to the gauges. These can be used on OEM systems for GM, Mopar, and Ford engines as well as Modules to connect to Holley, FAST, MSD, MegaSquirt, and AEM EFI systems. This will save you from duplicate sensors and extra wiring.

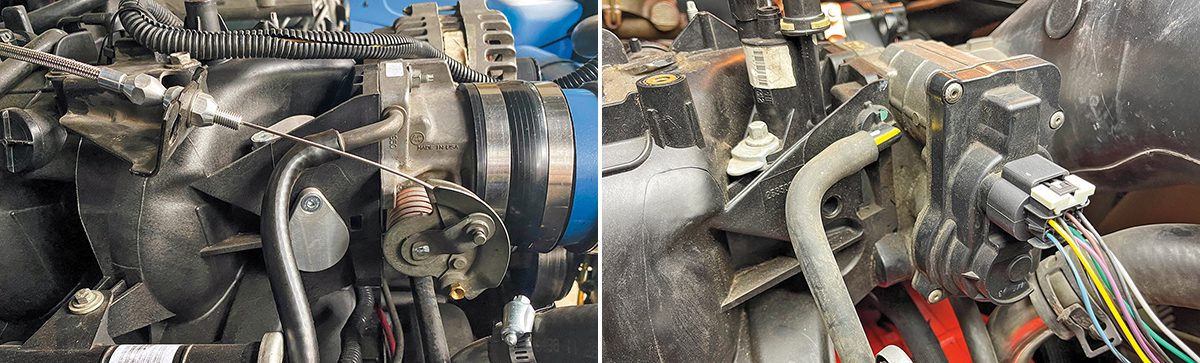

THROTTLE CHOICES

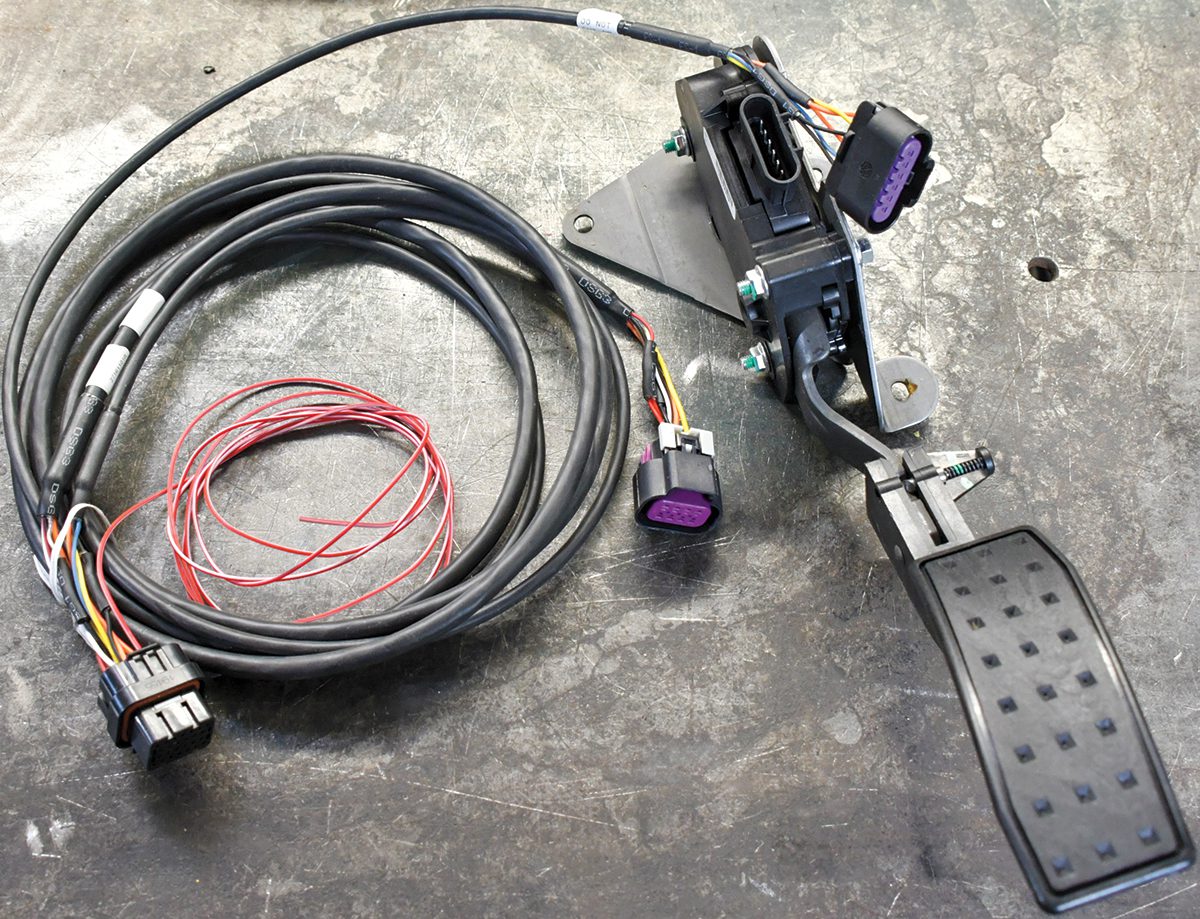

New engines haven’t had a mechanically operated throttle in quite a number of years and if you’re moving to a modern drivetrain or EFI system, you will need to decide whether to run a cable to control the throttle blade or go with an electric Drive-by-Wire setup. This is important to decide early as the wiring harness or even the ECU you use may be different.

Most hot rodders have never been happy about the pedal feel or reaction with a DBW system and usually plan to swap over to a cable-driven throttle. There are plenty of throttle bodies and linkage setups that allow for a mechanical throttle setup, however there are also things to be said about making the move to a DBW pedal, too.

Before even choosing an electronic fuel injection system, decide if you prefer a mechanical throttle or a Drive-by-Wire throttle. Each has their pros (and cons), but you need to know before you order a harness or other components.

The primary benefit of going to a throttle-by-wire system is the clean look and lack of a cable and bracket across the intake. For example, a Holley Terminator supports a DBW system but requires a matched pedal and throttle body. If you’re running a factory GM ECU, you’ll need a pedal, throttle body, and a specific Throttle Actuation Controller (TAC). In short, do your homework on the throttle system so you make sure to have all the right parts and calibrations.

There are many Drive-by-Wire throttle pedal assemblies available so follow the EFI manufacturer’s recommendations. This GM example requires a six-pin connector, but there are also nine-pins and other applications.

FAST

FAST

Wired Throttle

When making the move to a port fuel injection system, one of the options you’ll need to plan for is whether to go with a cable-actuated throttle or a modern throttle-by-wire setup. FAST has been in the EFI game for decades and now offers a Drive-by-Wire version of their popular line of 102mm Big Mouth throttle bodies for LS intakes.

The new electronic throttle body uses upgraded components to provide an increase in airflow over stock and is designed to be plug-and-play for most stock Gen IV LS ECUs as well as aftermarket ECUs capable of handling DBW. The electronic throttle body features a high-torque motor for quick response, a dual return spring for reliability, and a non-contact throttle position sensor. The Big Mouth is finished in a durable and stylish satin black that will look great on the front of any engine.

WIRING

Don’t be intimidated by the wiring harness! Any new harness is going to look like a mutant octopus of sorts, but after taking a few breaths and laying the harness out on a work bench, you’ll see that it is well sorted and usually labeled clearly. There will be group for the injectors, another for coil packs, several engine sensors, and for some a transmission harness. Take your time, plan the routing and it will come together.

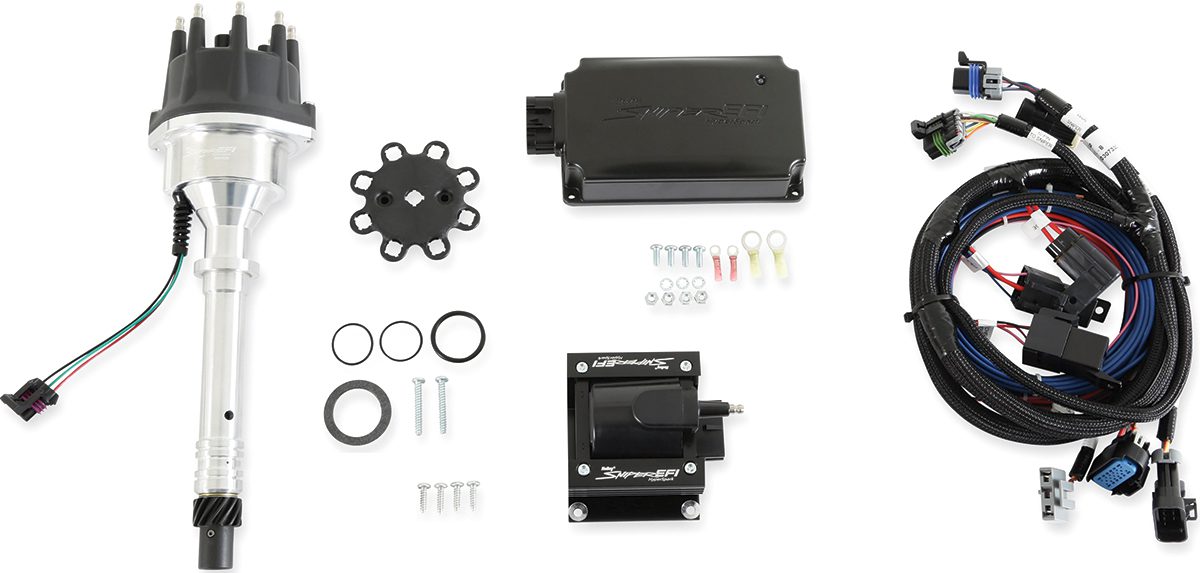

Holley

Holley

Timing for EFI

Upgrading to electronic fuel injection is a major part of achieving improved performance, but if you really want to get your engine management system dialed in, having the EFI control both fuel and spark is ideal. Holley’s new HyperSpark Master Kits were designed to complement the Sniper EFI system by giving you control over both the EFI and the ignition timing.

The system is based on a CD ignition box, billet distributor, high-output coil, and an easy-to-install harness that has only four flying wire connections; battery positive and ground, switched 12-volts, and fuel pump power. A Hall-effect pickup and unique rotor phasing tool make setting up the distributor and rotor position easy, giving you control to adjust the timing through the Sniper’s handheld monitor.

Two of the most important connections in an electronic fuel injection system are the main power and ground for the ECU. Most are recommended to go right to the battery, or perhaps the starter solenoid. A separate source ensures a “clean” and voltage source for the ECU which is always best. Also, ensure there is a quality ground strap or cable from the engine to the chassis and battery. The importance of proper grounding cannot be emphasized enough for today’s modern rods. Poor grounds will cause all sorts of hair-pulling issues, so make sure everything is wired properly.

This is also a prime time to review the charging system of your car. Make sure the alternator is up to handling the current demands of an electric fuel pump and the ECU. Other electronics such as cooling fans, A/C blower, and lighting are all pulling from the battery, so make sure the charging system and other wiring is up to snuff.