Paul Atkins is Known for Incredible Interiors; His Hot Rod Shop Crafts Equally Impressive Cars

For years, the well-executed stitchwork from Paul Atkins Interiors and Hot Rods has appeared regularly in some of the country’s top award-winning street rods and show cars. His upholstery creations have set the custom-interior bar for nearly four decades from his shop in the small Alabama town of Hanceville (population about 3,200).

But for nearly half as long, Paul’s hot rod building operation has quietly matched the accomplishments of the fabric and leather craftsmen. In fact, there is so much work that the waiting list for customers in nearly three years out. Paul says that at this point he’s not adding to that list.

Two recent builds to come from the Atkins shop, which also happen to be station wagons, are Fred Hardee’s ’52 Nash with a Roadster Shop chassis and LS3 power (shown later in this story), and Derek and Eileen Eisenbeisz’s ’58 Chevy Yeoman, which has an LT4 engine in its RS chassis. Both cars showcase the clean, tasteful style delivered by Atkins.

- Atkins definitely appreciates hot rod history, as evidenced by the famous So-Cal Streamliner built by Alex Xydias and driven by Dean Batchelor in the late-’40s, which Atkins now owns and keeps on display in the shop lobby.

Repeat Customers

Paul says that since day one, the hot rod shop hasn’t needed marketing efforts to keep busy turning out full builds as well as upgrades (aftermarket chassis and LS engine swaps) for older builds. That’s especially because a growing list of repeat customers keep coming back for more.

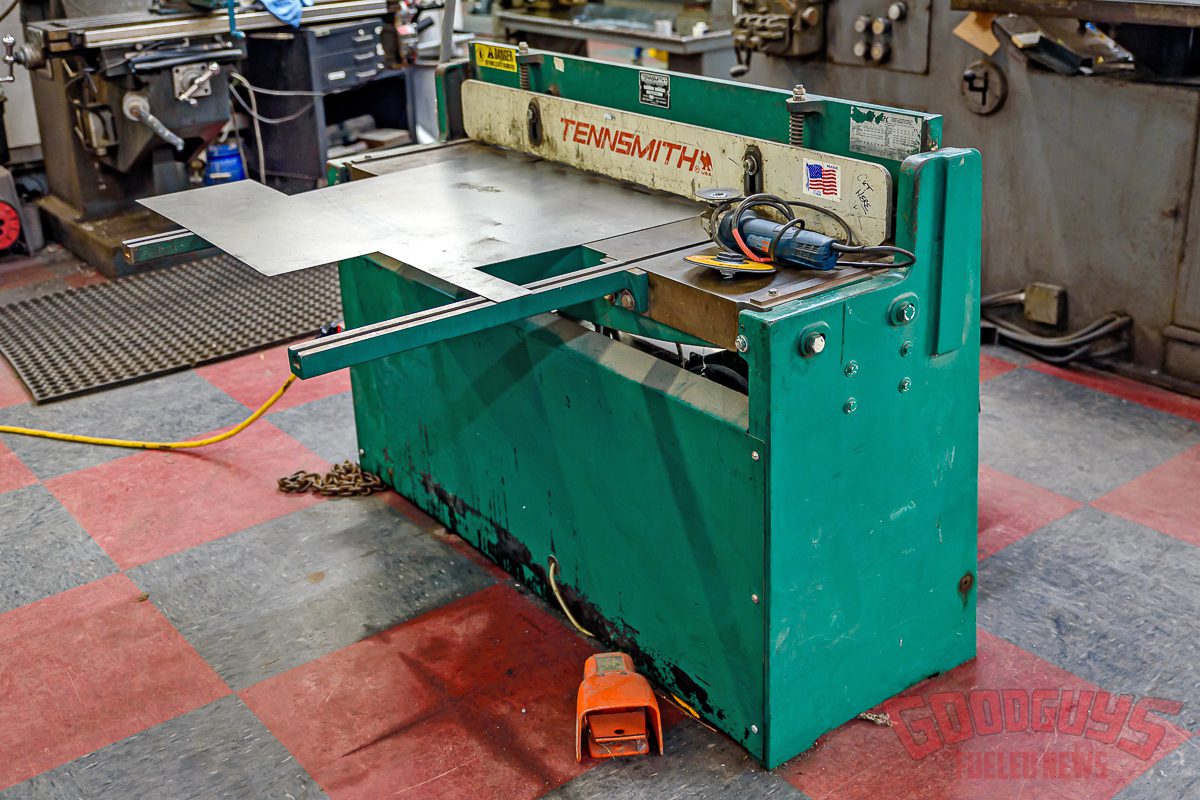

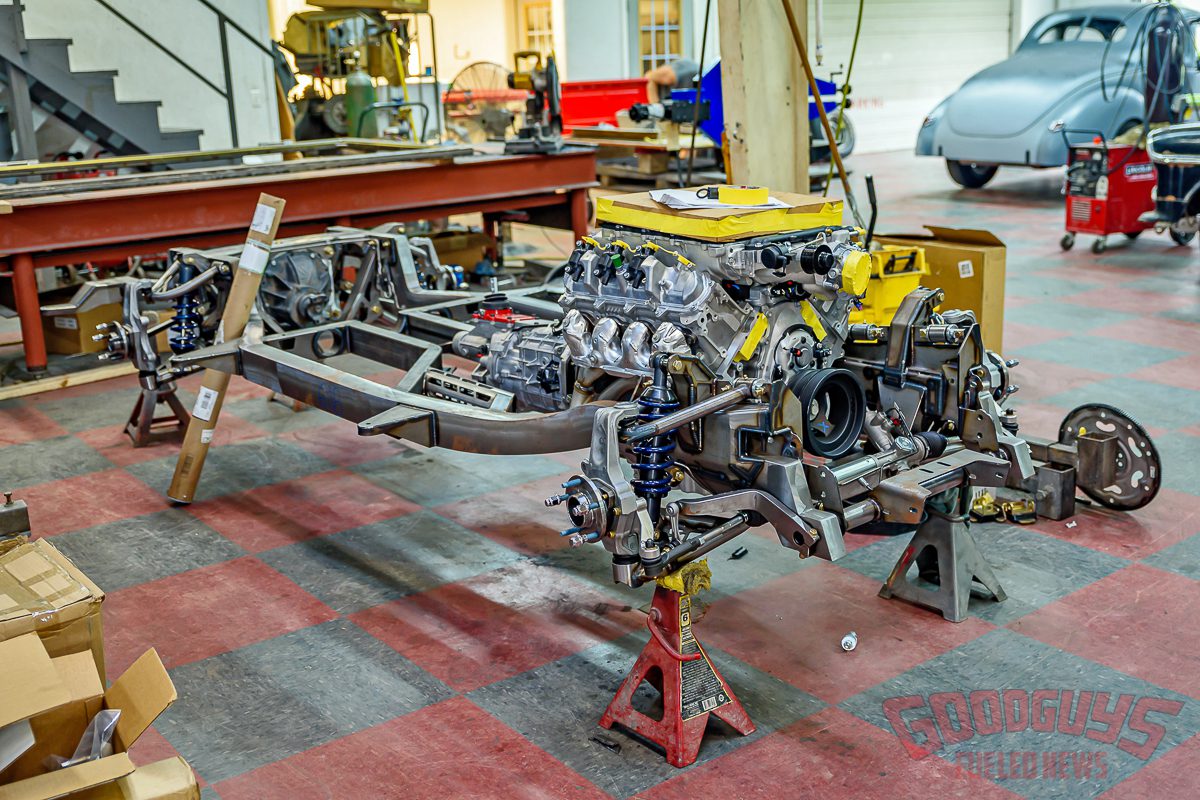

Like many builders, Atkins finds that it often makes more sense to start with a fresh chassis on ground-up builds. This Roadster Shop chassis and LT engine were getting prepared for a new project.

For example, the shop has turned out nearly 20 builds for longtime patron Doyle Thomas, who owns nearly two dozen Whataburger restaurants in east Texas. Thomas has a large collection of hot rods, customs, and Corvettes, many of which were built or upholstered by Paul’s team.

Part of what motivates the many repeat customers is a combination of the “Atkins Look” and the respect for the shop’s ability to weave metal fabrication, paint, and upholstery into a clean and cohesive end product that just works.

While all sorts of projects move through the shop, current builds include three ’63 Corvettes, a ’61 Corvette, and a ’68 Camaro. Paul says Corvettes are hot these days. “Because of what they’re bringing at auctions,” he says. “The guys building one don’t mind spending big money if they can get it back.”

- Corvettes are definitely hot these days, and many are getting modern street machine makeovers. This ’63 was one of four vintage ’Vettes in the shop when we visited.

- Paul maintains a good relationship with customers and other builders alike, which is why he’s still a go-to upholstery shop for many top names in the industry.

- Paul (at right) is shown here with Noel Irvin, who was picking up his ’64 Corvette, which was painted at Painthouse Texas before having its upholstery done by Atkins.

Design is Key

Paul says customers know the style that his shop produces, so creating the unique look for a particular project is relatively straight forward. Even though the customers know the shop’s work, Paul always has renderings produced, including the interior, so the customers and his crew have a plan to follow. It’s similar to an architect producing blueprints so the contractor has a set of instructions on how to build the building.

“I push a rendering,” Paul says. “We go through everything to get it right, then we follow that rendering.”

Knowing the Customer

Paul has learned over the years that taking time to know your customer before even starting to plan a project is critical. Building a relationship with the customer makes it much easier to create that first car to exceed the customer’s initial expectations. That extra effort pays off when customers keep coming back, he says.

Part of that challenge is working with the customers on critical elements like color. Paul says most customers come with a color choice, but he works with them to make sure it’s the right color. “That’s where the renderings come in,” Paul says. “A guy will come in with it in his mind, but when the rendering is done, we’ll do a few colors. He’ll often look at it and realize a different color looks much better.”

- This Ford woodie was ready for a fresh interior when we stopped by the shop last year.

Paul has advice for people who are looking to build their big-dollar ride, no matter what shop they’re looking at: Do your homework. Don’t commit to spending huge amounts of money without a deep dive into the prospective shop.

“You need to talk to guys who’ve been in shops,” Paul says. “Go in and look around. Ask about cars: How long they’ve been in the shop. If cars are there for three or four years, that’s not good.”

Paul warns about putting too much belief in online reviews, especially bad ones. “Online bad reviews are like the guy who complains about a restaurant because he wanted a filet at a McDonald’s price,” Paul says.

Staff and Supplies

Another critical element in the shop’s longevity is maintaining a team of skilled workers who can work together. Having long-term employees means repeat customers know that the people who built a previous car will most likely build the next one.

One challenge is finding good candidates when openings occur or when Paul wants to increase the size of the staff. Because the shop is in rural Alabama, there isn’t a ready supply of qualified prospects locally. One way around this dilemma (which is not unusual in the business) is to find local prospects and train them. Kind of a do-it-yourself apprentice program.

With the ability to do bodywork and paint on-site, Atkins can avoid potential schedule conflicts and snags that can come up when dealing with outside shops.

While styles change incrementally, Paul faces the same abrupt challenges as his fellow builders because of the pandemic and supply-chain issues. Before 2020 Paul purchased parts when needed, knowing that suppliers were operating normally.

For example, pre-2020 Paul says he would order a steering column about 10 days before it would be installed. Now, he says, once a project is ready to begin as many components as possible are ordered, even if they will sit on a shelf for several months.

Paul says many suppliers are just starting to catch up on their components, but others that require skilled workers to operate machinery are having trouble finding qualified candidates. But those supply-side issues are improving, he says.

Managing the Build

Another advantage for Paul in managing long-term builds is that so much is contained within the shop. Since the hot rod shop includes a paint booth and is connected to the upholstery operation, very few aspects of the build need to be outsourced. Plating, for example, depends on outside vendors, but by controlling so much of the project in-house, Paul says he can better manage the schedule.

It’s a formula that obviously works well for Paul Atkins Interiors and Hot Rods, so we can look forward to seeing many more top-notch builds roll out of the shop in the future.

Paul Atkins Interiors and Hot Rods

Paul Atkins Interiors and Hot Rods

1369 County Road 649

Hanceville, AL 35077

256.352.9608

www.paulatkinsinteriors.com

Photos by Shawn Brereton