Paul Bosserman Carries on a Family Tradition of Fabrication and Craftsmanship at Old Anvil Speed Shop

Paul Bosserman grew up in the historic Shenandoah Valley region of Virginia. In fact, Bosserman’s family can trace its lineage back 300 years in the area, and that means time-honored traditions can’t be too far behind.

Paul Bosserman grew up in the historic Shenandoah Valley region of Virginia. In fact, Bosserman’s family can trace its lineage back 300 years in the area, and that means time-honored traditions can’t be too far behind.

Paul’s dad, Doug Bosserman, worked in a precision machine shop most of his life (he just recently retired after working there for 57 years), but still found time to build hot rods back in the ’60s, including a channeled and 392 Hemi-equipped Model A coupe. When Paul was a teenager, he worked at the same machine shop, learning from all the old guys who did everything by hand and adhered to a strong work ethic.

Though his dad gave up the coupe when Paul was young, Paul had Hot Rod magazines from 1968-72 stacked up in his bedroom as a pre-teen, and he read and re-read them endlessly. It gave him a dream about visiting California to see all the shops he’d read about – a dream amplified by a music teacher who frequently played The Mamas and the Papas’ “California Dreaming” in her classroom.

In the showroom is the chassis for a ’33 Chevy sedan delivery built by Paul’s dad back in ’60s (now sporting an injected 401c.i. Nailhead backed to a 4L60E trans) parked next to a 1959 Alfa Romeo Sprint Speciale that is being restored. The ’46 Chevy truck in the back is a future project and sits on an Art Morrison chassis with air springs.

- This milled aluminum support adds rigidity and replaces the old door panel that held the window, door, and latch mechanisms on a ’33 Chevy sedan delivery

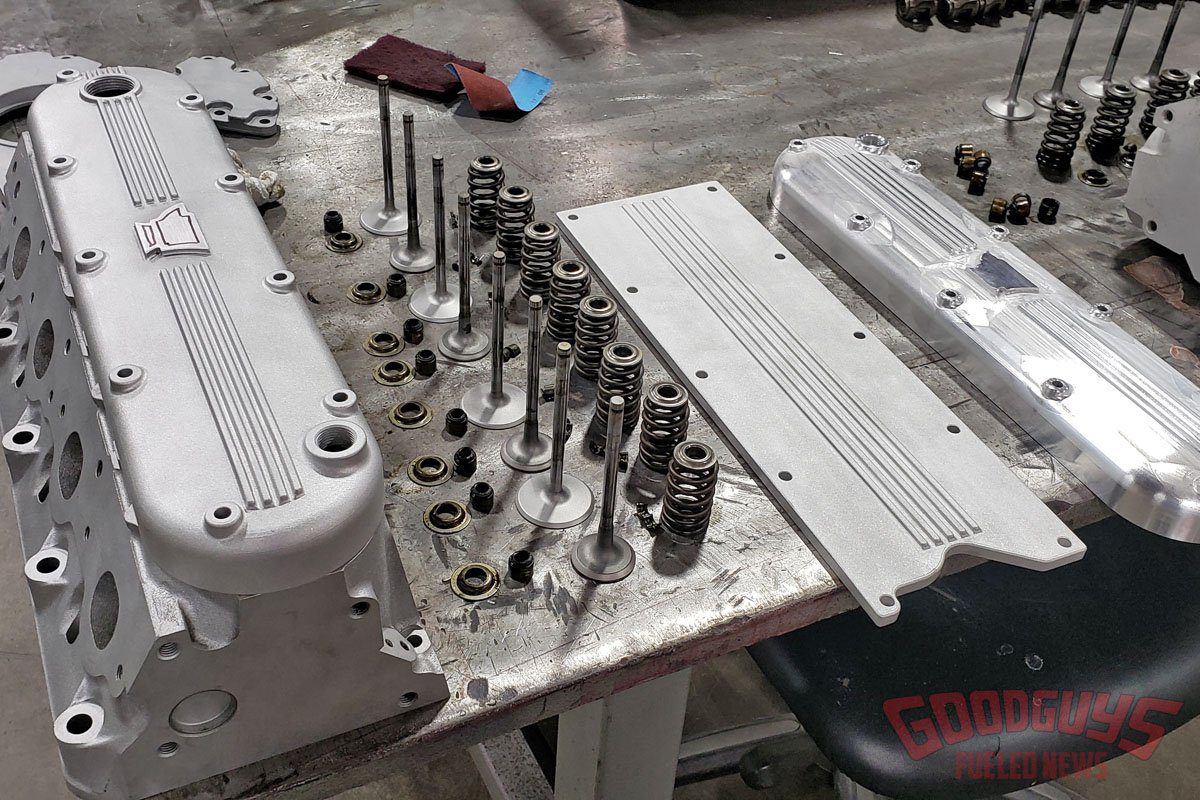

- This is some of the machine work Paul is doing for an LS1 for a ’66 C10. He designed and milled the valve covers and valley plates, then shot-peened them and will add some Cerakote for color.

By the late ’70s, Paul’s dad started taking him to the huge Hershey car show and swap meet in Pennsylvania, when vintage car restoration was very popular. By the time he was 15, Paul bought his first car: a non-running ’57 Chevy two-door hardtop for $2500. The floor pans and trunk area were gone from rust, so he learned how to weld by fixing his own car. He restored it to stock (adding a Continental kit) and drove it into his early 20s.

Other wide-ranging projects in the shop have various work orders, like the ’55 Chevy panel truck in the rear (fuel injection system and wiring), the ’67 GTO (roll cage, motor upgrades), a ’64 Lincoln Continental (new transmission and air ride), a ’49 Mercury (new chassis, LS engine and 3-inch chop), and a ’69 AMC Rambler Scrambler (new suspension and fab work).

One of his first jobs saw Paul working for a blade manufacturing company, where he learned how CNC machines worked and gained knowledge of metallurgy. This tied in nicely with the three years of mechanical engineering classes he took at Virginia Tech.

Old Anvil’s Eric Ladesma does a lot of sheetmetal finishing and is working on the hood scoop and floor pans of a ’67 Mustang, which was a coupe and is now a fastback (above). A 454c.i. Windsor small block (with a Dart block, a Holley Dominator fuel injection, a ProCharger, and Trick Flow heads) should produce around 1500hp (below).

On a summer break Paul started doing some drafting work for a fabrication shop for the local mills near his home. They did work on a massive scale, using 30-foot long lathes that had a 48-inch diameter, or a press brake that could easily bend half-inch plate, further expanding Paul’s fabrication knowledge.

Starting life as a ’67 Camaro convertible, this project – dubbed the “Z2X8” – uses two front-wheel-drive 5.3-liter engines out of a Super Sport Monte Carlo (one aft-mounted and one fore-) with each fed by a turbo and each generating about 750hp.

Ever seen a ‘31.5 Model A? Joking aside, Paul recently completed the fabrication on this coupe by adding parts of a ’32 Ford five-window coupe roof (from United Pacific) to a late Model A body, chopping it a few inches along the way.

By the mid ’90s Paul had opened his own fabrication shop, filling it with the tools he had grown up around. This led to opening another shop, Metal Magic, where he found success building commercial stairs and handrails. That business lasted until 2008, when construction work evaporated due to the economic downturn. Fabrication work became scarce, but Paul was able to hook up with a British sports car restoration shop that also had a ’52 Vignale Ferrari that already had some work done by hot rod metal master Craig Naff. A lot of intricate trim pieces still needed to be made, which Paul was able to do, and the vehicle ended up being a 99-point car displayed at the Cavallino Classic in Palm Beach as well as at the Pebble Beach Concours in California. The coachbuilding techniques became another addition to Paul’s resume,

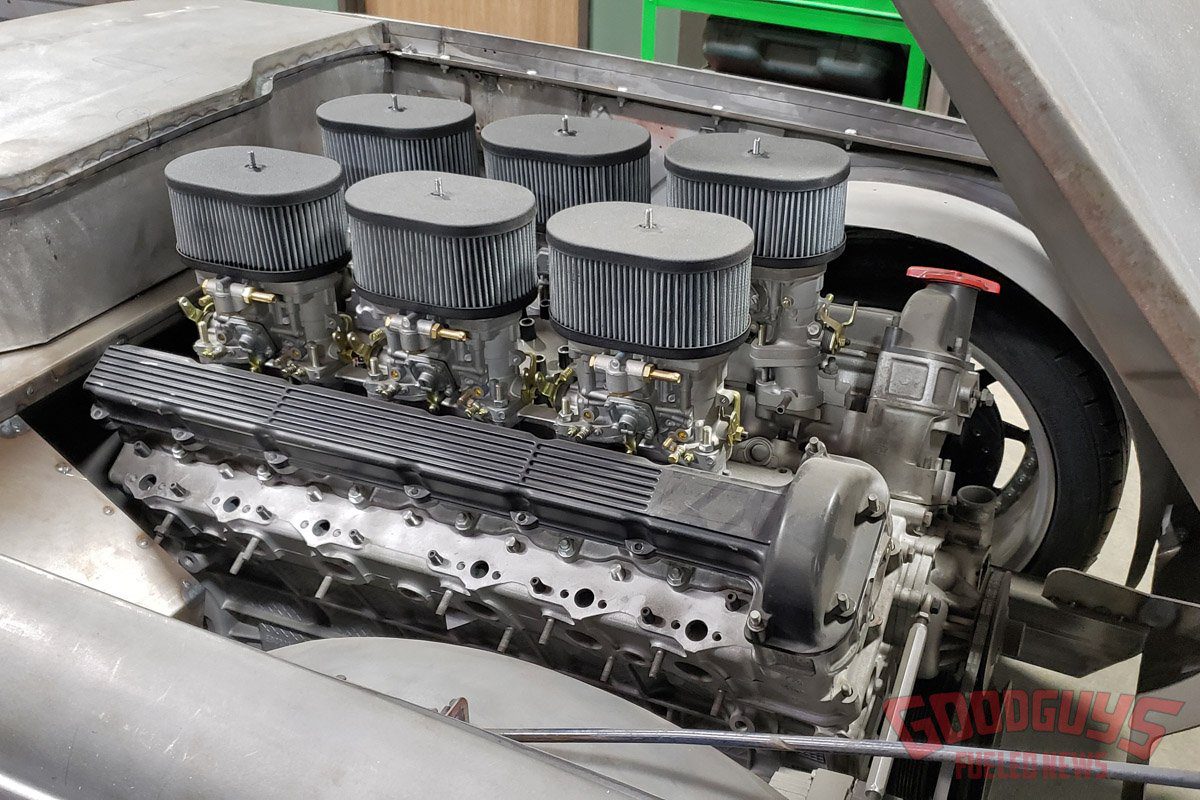

A ’74 Triumph TR6, sitting on a scratch-built IFS/IRS chassis, had its body stretched 6-inches in the cowl area, window channels welded shut for a true roadster look, and a Jag 6.2-liter V12 with six DCNF Weber carbs installed for power.

While working on the Ferarri, Paul took some time out to travel to the Rockabilly Rumble car show in Virginia and was introduced to a young woman named Jenna who was visiting from California. Paul and Jenna hit it off and, after visiting her in SoCal in 2013, he then returned in 2014 to see her and the Grand National Roadster Show. By this time, Paul knew he wanted to be in SoCal, so he brought along resumes to hand out. A job offer from Troy Ladd at Hollywood Hot Rods brought Paul to California in mid-2014.

Old Anvil got this ’36 Ford coupe in for repair work (crushed rear apron), plus a new chassis and floor. Paul also redesigned the stubby decklid, fabbing it to be longer like a ’37 Ford.

After a year with HHR, Paul moved south to work for Shine Speed Shop for a couple of years, and then for Scott Bonowski at Hot Rods and Hobbies. After working on a handful of AMBR contenders through different shops, Paul decided to open his own place, call his own shots, work on what he wanted to, and build good relationships with his customers. In May of 2018, he opened Old Anvil Speed Shop in Orange, California.

Old Anvil Speed Shop was opened in 2018 and now covers a combined 13,000 sq. ft. of space.

This ’52 GMC project, designed by Eric Black, is slated to get an extended cab, a 2-inch chop top, and aluminum bed sides and hood. It already wears custom-machined wheels – a three-piece, pin-drive, 19-inch design penned by Eric Black. Paul did the CNC programming to have them milled in 3D at the shop.

Along with his now-wife, Jenna (they married in 2017), the couple has six talented fabricators working for them and 15 or so customer cars in 13,000 sq. ft. of shop space. He enjoys designing and milling one-off pieces to further a car’s design but, because the types of cars being worked on are quite varied, the common thread is they’re all being built with a meticulous attention to detail. And there’s always a bit of custom coachbuilding thrown in to make each vehicle just a little different from any other car out there. The shop farms out paint jobs and upholstery work, but everything else – from custom chassis work, distinctive drivetrains, upgraded suspensions, and a whole lot of creative metal fabrication – happens right at Old Anvil. Paul also works with designers such as Eric Black, taking illustrations and figuring out the programs needed to have parts CNC milled.

Along with his now-wife, Jenna (they married in 2017), the couple has six talented fabricators working for them and 15 or so customer cars in 13,000 sq. ft. of shop space. He enjoys designing and milling one-off pieces to further a car’s design but, because the types of cars being worked on are quite varied, the common thread is they’re all being built with a meticulous attention to detail. And there’s always a bit of custom coachbuilding thrown in to make each vehicle just a little different from any other car out there. The shop farms out paint jobs and upholstery work, but everything else – from custom chassis work, distinctive drivetrains, upgraded suspensions, and a whole lot of creative metal fabrication – happens right at Old Anvil. Paul also works with designers such as Eric Black, taking illustrations and figuring out the programs needed to have parts CNC milled.

This ’68 Charger had been at other shops but is being cleaned up and finished at Old Anvil. The Roadster Shop chassis holds a 560c.i. Hemi, and the car is now out for paint.

An interior jig keeps everything aligned while they swap the old wood out for steel tube on the ’33 Chevy sedan delivery that belongs to Paul’s father, with some of it to remain as part of the new support structure (above). Sergio Saucedo, a veteran fabricator, came to work at Old Anvil about three years ago and is adding some mini tubs for the cheater slicks on the sedan (below left).

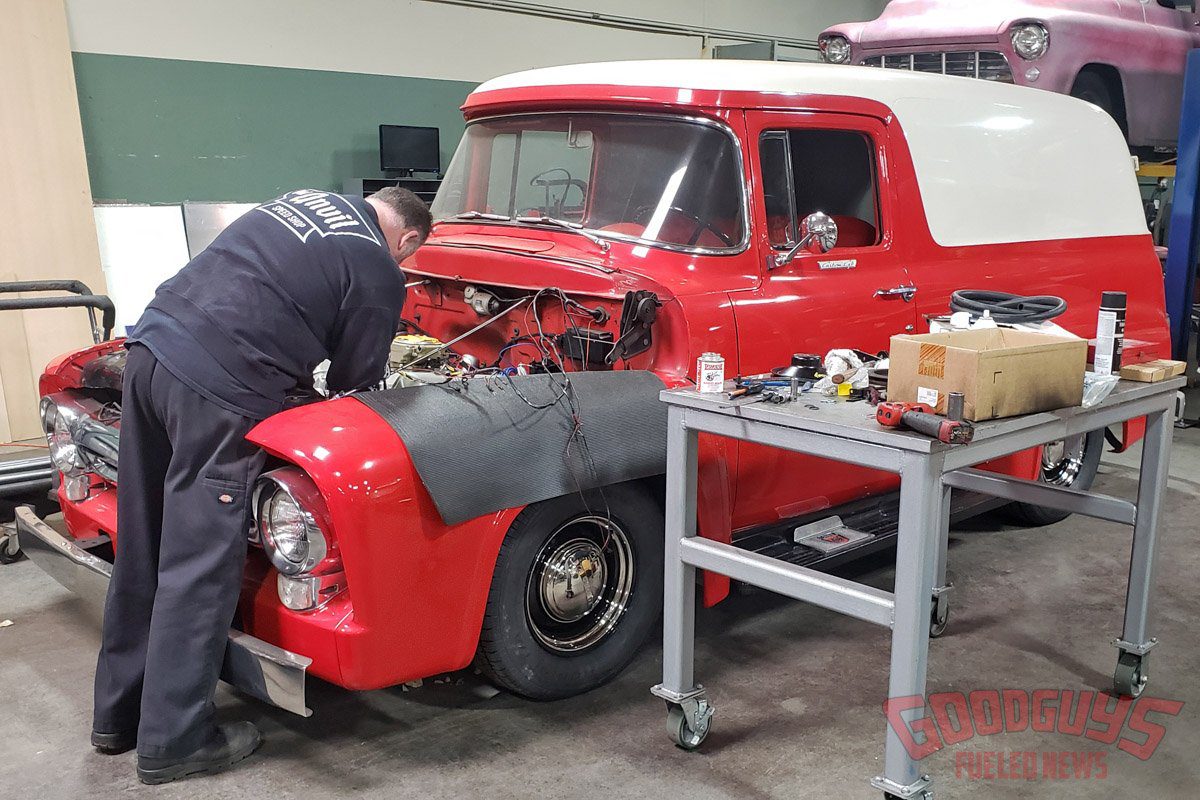

- A ’56 Ford panel truck is getting some attention from Old Anvil’s Bruno Casella, who is in the middle of adding a Holley Sniper electronic fuel injection to an upgraded Ford 390c.i. T-bird engine. Other work includes new rear and front suspension (with power rack) and Wilwood discs on each corner.

Paul’s great-grandfather used to shoe horses while managing a fruit farm 100 years ago and, back then, a horse was most folks’ main method of transportation. At 49 years old, Paul still uses his great-grandfather’s farrier’s anvil to shape metal and stay busy working on today’s preferred choice of transportation: the automobile. He’s using his decades of education, both practical and hands-on, to carry on his family’s tradition by giving new-age horses their shoes – several hundred at a time!

Paul’s great-grandfather’s anvil is at least 100 years old, and he uses it just about every day – here on a ’32 Ford roof section to be grafted into a Model A coupe.

Old Anvil Speed Shop

Old Anvil Speed Shop

1420 N Glassell St

Orange, CA 92867

657-223-9889

www.oldanvilspeedshop.com

Facebook | Instagram

Photos by Eric Geisert

Old Anvil Speed Shop

Old Anvil Speed Shop