No Compromise in Cooling – SPAL’s Sealed, Brushless Fan Technology Grows

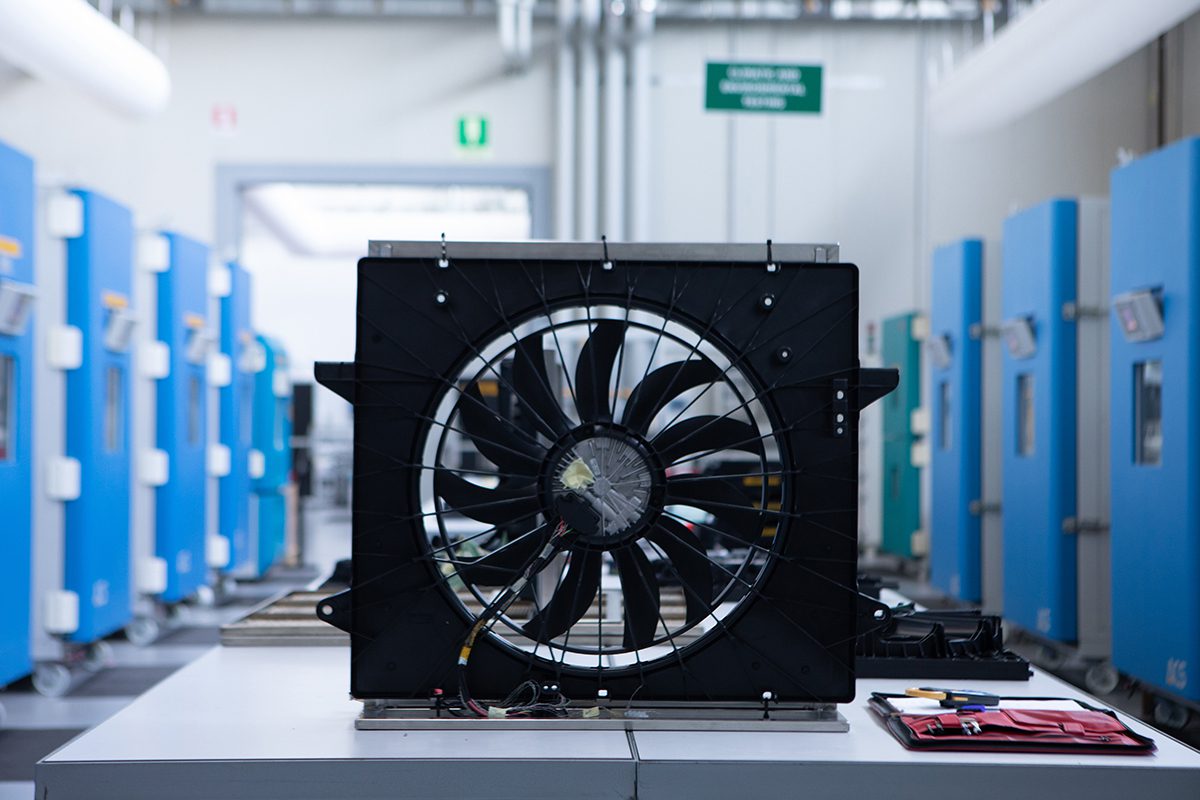

SPAL USA, located in Ankeny, Iowa, ha been designing and manufacturing OEM and aftermarket electric cooling fans since 1959. Today they offer an expansive line of fans including their sealed, brushless (SBL) products that have proven themselves through the most challenging environmental conditions in fluid, electronics and battery cooling, HVAC, racing and other settings.

SPAL SBL fans feature motors sealed to IP6K9K standards (waterproof/dustproof & waterjet capable), integrated power and signal electronics, “soft start” technology (eliminates electrical in-rush spike), digital control for smooth and reliable operation, temperature sensor options for full variable speed control, reduced axial dimensions, low weight and high efficiency. SPAL SBL motors also feature patented “Sine Wave Technologies”, resulting in quieter and smoother running motors that, in turn, reduce NVH and “felt vibration” levels in electric vehicles.

Additionally, the brushless motor design also reduces the number of wear components versus standard brushed technology to deliver extremely long-lasting life. All SPAL SBL motors are rated to operate in high-temperature conditions, higher than typical DC motors on the market today, and are the ideal fit for almost any and every application requiring extreme cooling.

To safeguard itself and prevent premature motor failure, SPAL SBL motors feature numerous protective features to detect problematic situations. To avoid damage to the motor it provides automatic power de-rating in severe over-temperature operating conditions that allow the fan to run at lower speeds rather than cause permanent motor failure. It also checks for over- and under-voltage and locked rotor conditions to prevent catastrophic failures to the fan motor. SPAL SBL technology is specifically designed for applications where airflow performance, low power consumption, automatic speed control, long motor life, and high efficiency are key requirements.

SPAL’s product design, tooling, performance, and validation testing, automated motor manufacturing, injection molding, robotic product assembly, electronic PCBs for brushless motors, and 100% end-of-line testing of all products are done entirely in-house. For more information about their line of sealed, brushelss fans check out SPAL USA.