1930 Ford Model A Pickup – Picking up the Pieces

The early bird gets the worm but the second mouse gets the cheese. A queso-riffic metaphor that applied to Vergil Dawson that time he accompanied his buddy Dave on a trek to Bakersfield to look at a dismembered body. What they discovered was an assemblage of 1930 Ford Model A Pickup parts strewn about a garage floor. Dave took one look and passed but Vergil was hungry so he made a quick deal and ran off with the bait. After trucking his pile of parts back to his Tehachapi, CA shop, Vergil set about baling-wiring, c-clamping, vice-gripping, duct-taping and bolting his prize back together to see what he had to work with and to lay out his plan.

After the requisite trip to DMV that goes with buying a pile of parts, the project was stripped back down to bones and Vergil commenced with building her up again. The factory 1930 Ford Model A Pickup rails received a 2-inch dropped front crossmember from So-Cal Speed Shop and were lengthened 7-1/2 inches in the rear to fit the 3.78-geared ’40 Ford spring-behind banjo rear. This dropped the ride height without losing too much ride quality. Converted to open drive, the housing was modified by Hot Rod Works of Caldwell, ID to accept Ford 8-inch type spider gears and 8/9-inch style axles & bearings making axle R&R much simpler. A pair of 42-inch ladder bars locate the rear with a stock Model A spring from Mac’s Antique Auto Parts, accompanied by Pete & Jake’s shocks and ’40 brakes. Up front, a So-Cal Speed Shop 4-inch dropped axle sports a Posies Super Slide spring with P&J shocks and ’40 brakes riding ’35 spindles. A Flaming River cross-steer box keeps it pointed forward with Chassis Engineering steering arms while a P&J steering stabilizer and panhard bar round out the steering system. Vergil boxed the frame and fabricated a crossmember to fit the S-10 T5 trans equipped with a Hurst short-throw shifter. The chassis and components were finished in Eastwood Extreme Chassis Black and roll on Rally America wires leading with 15×5″ wrapped in Coker’s B.F. Goodrich 670-15 bias-ply rubber followed by 15×6″ shod in Coker/BFG 820-15s in the rear.

When one part of the project stalled or he grew tired, Vergil would transition to a different aspect of the 1930 Ford Model A Pickup to break up the monotony. After excising and patching the typical rust you’d find in a truck of this era, Vergil filled & smoothed the firewall and modified & reinforced the rear floor and door pillars to accommodate 3-point seat belts. Up front, Guide 682-C style headlights from Speedway Motors bookend the Vintique deuce shell and insert supporting a Rootlieb two-piece hood. The bed carries a 20 gallon fuel cell hidden under a box built to resemble a vintage travel trunk. The hardwood bed floor stops at the trunk to allow the oversize tank to hang below and stay camouflaged. The headgate was raised to match the height of the tailgate and the bed is finished off nicely with a pair of wooden stake sides. The exterior was finished in Dove Grey single-stage acrylic urethane sprayed by Vergil in his backyard shed and Machinery Grey, which he farmed out to Mountain Paint in Tehachapi when winter temps proved too cold for the shed.

Creature comforts were important since Mary Jo Dawson loves hot rodding as much as her mate. The cabin features a Poliform deuce-style dash stuffed with AutoMeter gauges and is wired with an American Autowire Hwy 22 kit. An Ididit column is topped by a Grant banjo wheel. Stock seating was stitched by Hillside Interiors of Tehachapi in a luxurious Mist Grey ‘naugahyde’ from Symphony Classic Vinyl, with matching door panels and Storm Grey carpet from Luxury Auto Carpet completed by Vergil. Three-point seatbelts keep the Dawson’s locked down for the many miles of cruising they enjoy together.

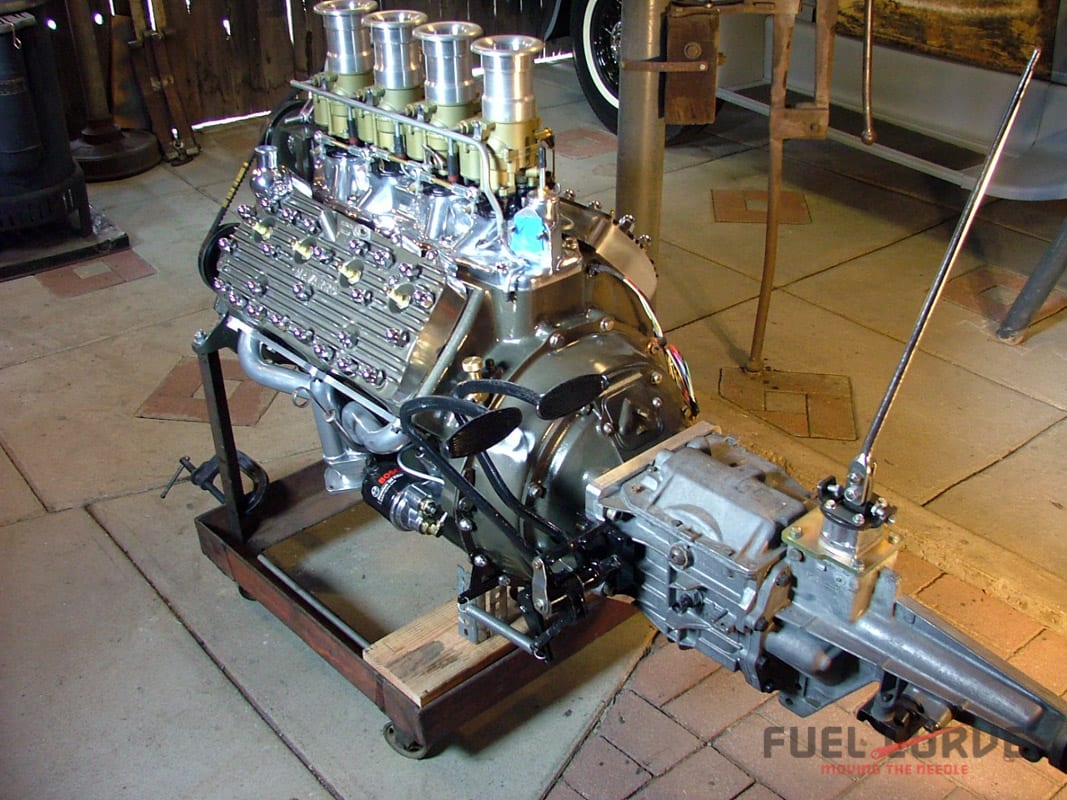

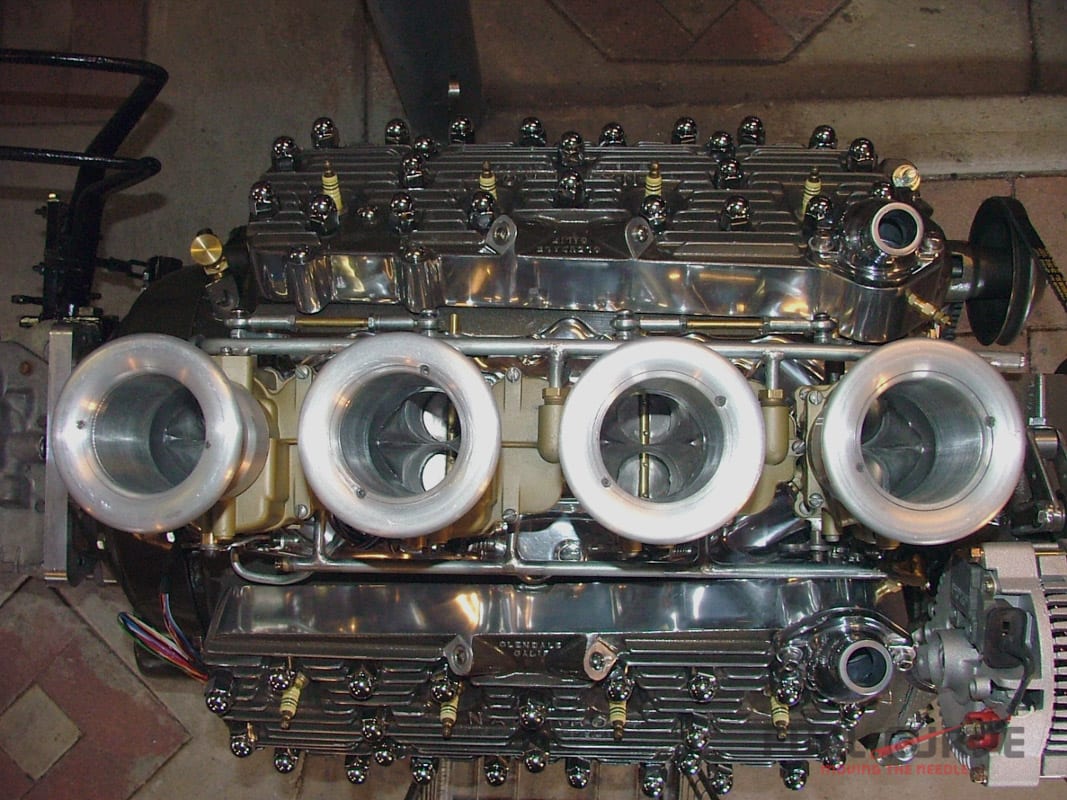

The real eye-opener in this project is the injected 276ci ’51 Merc 8BA; machine-prepped by Adams Metalizing & Grinding in Lancaster, CA and built by Vergil. It runs a stock-spec Merc crank with Ross forged 9:1, 3-ring pistons, a Schneider 270-F cam with Schneider valves & springs, and Navarro aluminum heads topped with an Edelbrock 4×2 intake sprouting Holley ECG-6 carbs.

Here’s where this traditional-looking flathead departs the past; those Holley carbs you see have been gutted and modified to serve as throttle bodies for the home-brewed electronic fuel injection system that Vergil cooked up in his laboratory. Vergil drilled the intake runners in the block to accommodate 8 Bosch side-feed injectors and somehow managed to stuff them and their required plumbing and wiring into the lifter valley under the intake manifold. Fuel is fed to the fuel rails through a gutted and modified fuel pump housing and until you notice spark plug wires going through the firewall, the engine appears to be a ‘normal’ hopped-up flathead. The carbs were bored out and sleeved with 1-3/8″ I.D. aluminum tubing and with the equalizing runners in the manifold blocked, act as eight individual throttle bodies.

Vergil also fabricated an air induction/filtration system into the 1930 Ford Model A Pickup featuring a pair of small fresh-air scoops that appear on both sides of the grill shell that feed a K&N filter element. A crank trigger trips the Electromotive Tec3r computer and 4 Electromotive coils provide fire for the sequential-injection system. The system includes a one bar GM map sensor along with O2, knock, cam & throttle position sensors and all the magical mumbo jumbo to make it run right for over 10k trouble-free miles so far. Spent gases are extracted through a pair of Sanderson center-dump headers and 2-inch tubing connects them to a pair of Magnaflow 6-inch round mufflers which rumble through a pair of turn down tips at the rear.

The sound is the sweetest music a hot rodder could ever hear. Vergil Dawson did it right. His 1930 Ford Model A pickup stays true to Ford’s pre-war pickup offerings yet gives traditional hot rod flair its due justice as well. Whether it’s climbing highway 58 back home to Tehachapi or coasting down to the valley below, this hot rod pickup turns heads.