Ironworks Speed and Kustom – Bakersfield’s Best

When Rodger Lee opened Ironworks Speed and Kustom in Bakersfield CA it was the result of a kick in the pants. A layoff from his job as a diesel mechanic was the boot. A native of Bakersfield, Rodger’s youthful interests play like the broken record of car guys everywhere; if it had moving parts, wheels and/or wings, he was into it. Automotive and diesel-tech classes, and a community classroom program at the local Caterpillar dealership were his curriculum. After high school, completion of UTI was followed by a job offer from the Cat dealership and it was during his time there that he bought a coworker’s ’57 Chevy truck. Years later that truck would become his catalyst for greatness.

It was 2001 and Rodger was already building stuff in a 700 sq. ft. ‘toy shop’ space. Rented after some hired-out fabrication work fell below his standards, he decided his money was better spent on the space and the tools to do it himself. With a few friends bugging him to work on their projects and a thousand dollars of “encouragement” from his mom, Ironworks Speed and Kustom was born. His first move was into a larger shop with an actual bathroom. After that, Rodger took any fabrication work he could get; building lumber racks and painting trailers mixed in with customer cars. Things happened fast and forced a couple of moves in the first few years, more than doubling their shop space with each move and adding staff as the business grew. All that growth eventually landed them in the 9800 sq. ft. shop they currently occupy.

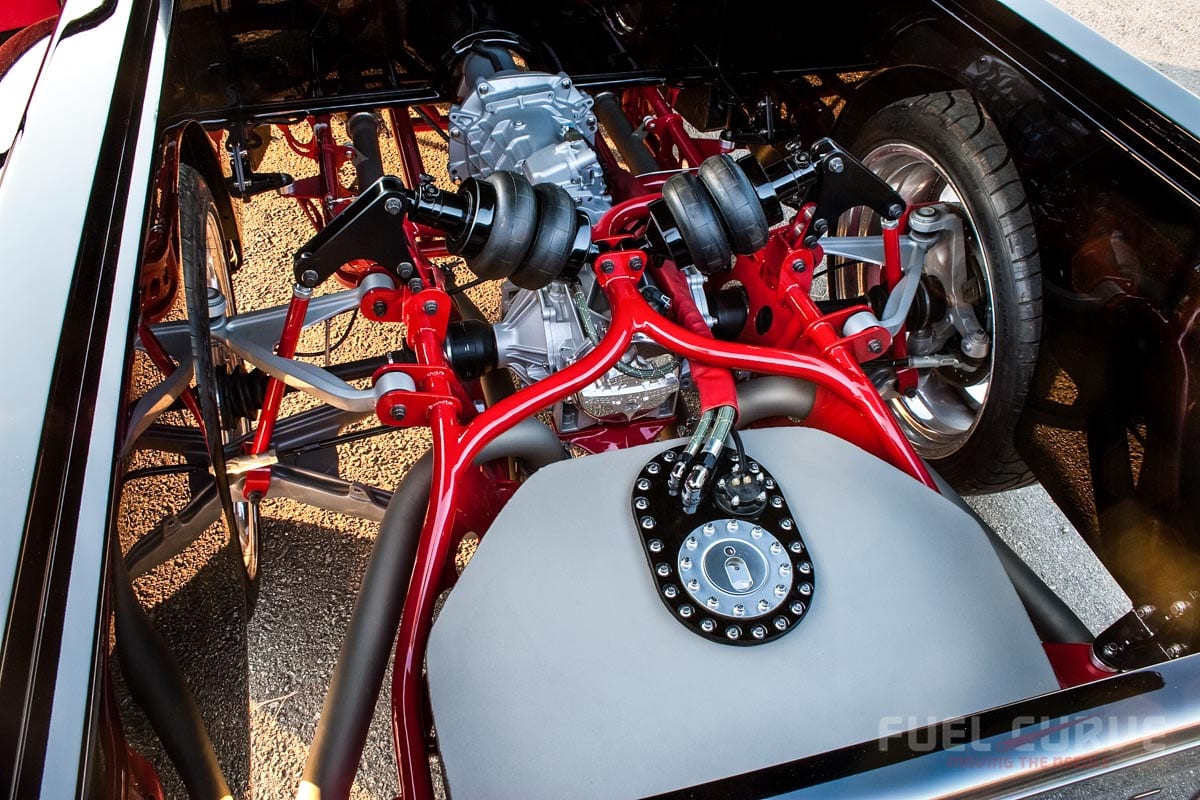

That old stepside ’57 had served as Rodger’s faithful daily driver and shop truck for several years but a steady flow of work required a newer/larger truck, and the ’57 was promoted to shop project. A tube chassis is the foundation for the Kinsler stack-injected LS2 and features a C5 transaxle mated to a T56 trans. Rodger designed and built a cantilever rear suspension utilizing RideTech Shockwaves, and the build includes Wilwood brakes, Budnik Muroc 2 wheels, custom red leather interior and a long list of custom-machined parts and body modifications.

“The truck allowed me to show off the chassis and many other details that would have been lost under a car” Rodger said. The classic styling melded with a modern drivetrain also drew interest from enthusiasts in other segments of the automotive hobby. Ironworks Speed and Kustom began to draw customers with higher standards wanting turn-key builds. Since then, Lee and his team have been producing a nonstop stream of home runs.

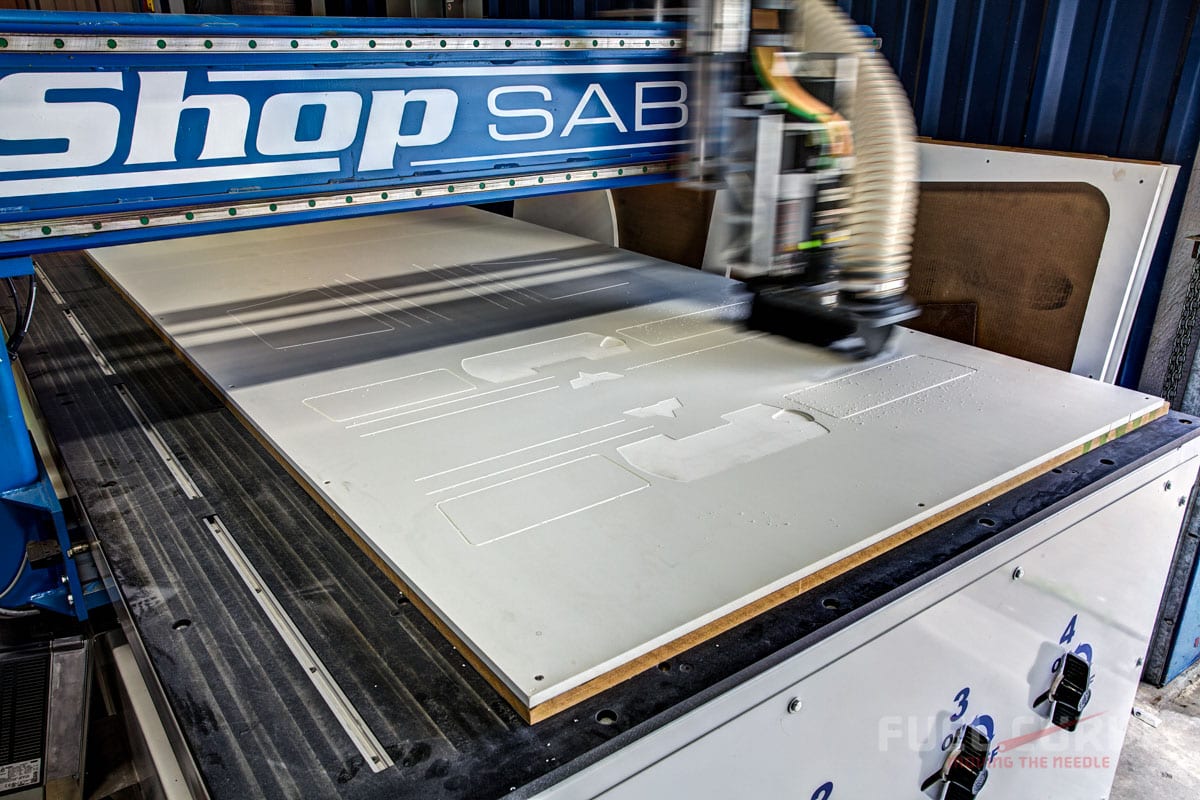

As ISK grew, Rodger worked at bringing more of the custom work in-house so he didn’t have to rely so much on outside sources. Along with the usual array of metal-morphing machines, Rodger acquired welders, brakes, benders, rollers, saws, a mill & lathe, power hammers and the English wheel that Rodger built in the early days. They brought in a CNC plasma-table and began designing parts in Solidworks, eventually adding a booth for in-house body and paint.

A 3D printer allows for fast prototyping of custom parts for fitment and fine-tuning prior to having them machined from aluminum. A CNC router is used to create custom interior panels and parts. All that growth resulted in a dozen team members, who enable ISK to make daily progress on 3 or 4 vehicles, in different build stages, simultaneously. The ISK team consists of Rodger Lee, his bride Shannon -who handles the business end of the business, with Mike, Lee, Randy, Tanner, Ryan, Heather, Brian, Rocky, Canaan, Jon and Jose in the shop building the dreams.

Making happy customers is the principal tenet at Ironworks Speed & Kustom. Rodger told us “We try different levels of builds to satisfy a customer’s desire. The goal is to match their expectations with their budget. You can’t have a million dollar Ridler-level car that costs $35k. It’s not going to happen. So we have a lot of discussion about the real use of the car and what they want to do with it and we try to be brutally honest. Most of the time it’s cheaper to just go buy a complete car close to what you want and change a few things to make it your own. But some guys like the build process and having a car unlike any others out there, so we go to the drawing board and spend the time to build the vision they see in their head or work to really focus that vision.”

Making happy customers is the principal tenet at Ironworks Speed & Kustom. Rodger told us “We try different levels of builds to satisfy a customer’s desire. The goal is to match their expectations with their budget. You can’t have a million dollar Ridler-level car that costs $35k. It’s not going to happen. So we have a lot of discussion about the real use of the car and what they want to do with it and we try to be brutally honest. Most of the time it’s cheaper to just go buy a complete car close to what you want and change a few things to make it your own. But some guys like the build process and having a car unlike any others out there, so we go to the drawing board and spend the time to build the vision they see in their head or work to really focus that vision.”

Striking a balance between satisfying customers and being a husband and a father keeps Rodger plenty busy. But he’s really good at both and that’s a testament to his talent, his team and his devotion.

Ironworks Speed & Kustom Project Gallery

1970 Chevelle SS

The Fairway Chevelle (one of several builds for Las Vegas car dealer Greg Heinrich) features a custom ISK-built boxed chassis CAD designed to accept C6 Corvette-based front suspension and runs a 4-link/panhard setup in the rear. It’s powered by an LSA crate engine backed by a Tremec Magnum T56, and features RideTech triple-adjustable coilovers, Wilwood brakes, and rides on 19 & 20-inch Gripp Equipped Laguna wheels.

1948 Chevy 3100

“Naughty Spice” rides on a custom, ISK-built boxed & tubular chassis with ISK custom tubular control arms and a 4-bar/panhard rear, Wilwood rotors while DynaTech 6-piston calipers and RideTech coilovers reside in the corners. Powered by a GM LSX 6.2L aspirated by a custom Magnuson Supercharger with a Hughes Performance 4L60E, it puts the power to a GM 12-bolt limited-slip unit turning 4.10 gears and Currie axles. The 19-inch Schott Mod 5 wheels are shod with Bridgestone rubber. Body mods include a 1-1/2″ chop, the cab lengthened 3 inches in the doors and the body sectioned 1-3/4”. The nose of the hood was laid back, the grill was narrowed and retapered, and the running boards, wheel openings, etc got a makeover as well. Nearly every panel on this truck was finessed in one way or another, each so subtle it’s hard to tell what’s different unless it’s parked next to a stock one. Ron Mangus stitched the Italian leather & suede interior.

Fairway ’55 Chevy

Fairway 1967 Camaro

Whipple 1957 Chevy

One hell of a company car, the Whipple Superchargers ’57 Chevy is all business with its 4.5 litre supercharger force-feeding a built LS9 backed by a 4L80E trans. Carbon fiber abounds on this beauty and includes both bumpers, the upper grille bar, and a custom intake tube set against HRE’s Frozen Red custom anodizing on the engine. It rolls on a modified Art Morrison chassis sporting C6-based suspension up front with RideTech Shockwaves for racing stance and Wilwood brakes with custom-anodized Frozen Red calipers. HRE S209 wheels in 20×9 and 21×12 with Frozen Red hoops are wrapped in Michelin rubber. Subtle body mods are a running theme with ISK builds and this ’57 doesn’t disappoint. Two inches have been lopped out of the front fenders ahead of the axle centerline and the cowl vent was eliminated, allowing the hood to move rearward with the nose, thus saving it from the cutting wheel. Some loft was removed from the roof panel above the rain gutters, it’s not chopped but visually lightens the top of the car. Performance cues include a spoiler-lip under the carbon front bumper and a diffuser with center exhaust ports below the carbon rear bumper. The ’57 wears PPG Telesto Gray (A Lamborghini color), and sports Whipple graphics on the hood. All the bright trim on the car was coated in gray. The Gary Ragle-designed interior was brought to life by Sid Chavers in a gripping contrast of red and black leathers.

1962 Chevy

The twin turbo bubbletop features a custom ISK chassis; C6 suspension up front with RideTech coilovers and Wilwood brakes. It rolls on HRE 20 and 21-inch monoblock wheels shod with low profile Michelins. The LS2 is fed by a pair of 62mm turbos which are smallish to minimize lag and topped by a unique induction system designed by ISK that features many one-off machined or 3D printed parts. These include the intake manifold and plenums, and most of the instrument panel, dash and console bezels. Another outstanding interior by Sid Chavers shows why he is ISK’s go-to guy. Minimal body mods include custom taillights and some subtle changes to the nose, all doused in PPG Grigio Scuro -a vintage Ferrari hue.