Subtle Mods and Custom Metalwork Complement the Chopped Top on the Goodguys Giveaway 1932 Ford Coupe

Last month we showed you how the team at Streamline Custom Designs chopped the top on the 2024 Goodguys Giveaway 1932 Ford five-window coupe. It was a milestone event for this in-the-works hot rod that will be unveiled this summer, but it was far from the only metalwork to be done on the body. While the Streamline team had the benefit of starting with fresh no-rust reproduction sheet metal from United Pacific, there was still plenty of fine tuning required to get the body just right, plus some subtle mods they wanted to perform to give the Deuce a truly distinctive look that corresponds with the Eric Black rendering.

Let’s start with some of the un-glamorous fabrication work that most people won’t notice when the car is finished. The raised rear spring crossmember would protrude through a stock trunk floor, so the Streamline team built a custom sub-structure to raise the floor. Front, rear, and side pieces were fabricated to fit the contour of the frame and create a flat top surface just above the peak of the crossmember arch.

With the body back on the chassis, you can also see the frame for the dividing panel between the trunk and interior. This will eventually support removable panels for the Holley Terminator X ECU, Kicker Audio, American Autowire harness, and other electronics.

Some of the metalwork was basic, necessary car-building stuff, like fabricating floor panels and crafting a custom transmission tunnel to cover the Bowler Tru-Street 4R70W transmission. They also built a custom sub-floor structure in the trunk area, which will raise the floor to accommodate the raised rear spring crossmember. Ahead of that is custom bracing between the trunk and interior, which will eventually support removable panels for the engine ECU and other electronics.

When assembling and fabricating floor pieces, one major consideration was accommodating the new Bowler Tru-Street 4R70W.

With the main floor panel and toe boards in place and trimmed to fit, the team could start on building the transmission tunnel, fitting it around the Lokar shifter. The tunnel was built in three pieces.

Those three pieces were then welded and metalworked into one piece, which was temporarily screwed into place and will eventually be a removable piece when finished.

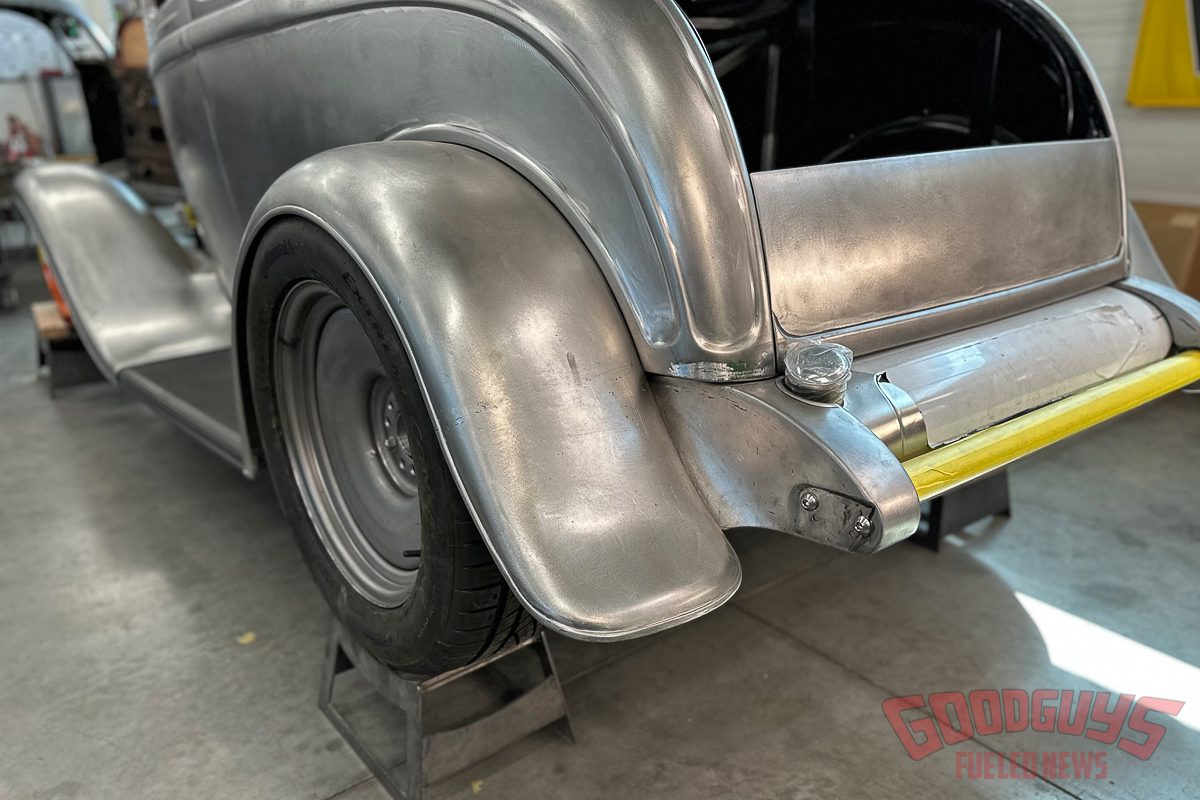

Other mods were more aesthetic, specifically some of the subtle alterations on the fenders. The front fenders were extended 1/2-inch by adding a section at the rear, where the fender meets the running board. This stretches the front just slightly, and better centers the front wheels in the fender arches. The rear fenders were shortened 3-inches to visually lighten up the rear, and custom frame horn covers were fabricated to give the back end a tidier look. The fuel tank came from Tanks, Inc., and was tucked up tighter to the body and the frame rails were shortened and raised.

Look closely at the front fender and you’ll see where it was lengthened ½-inch at the rear. This visually enhances the front of the car and better centers the front wheels in the fender arches.

At the rear, the goal was opposite – to shorten the fenders slightly. This required first cutting off the ends. (Note also the custom frame horn cover built by Streamline in this photo.)

Approximately 3-inches was removed but note how this was done with a stepped cut to aid in aligning the two pieces for welding. Final welding and metalwork was done with the fender off the car.

Moving to the other side to show the final result, the shortened fender is one of those subtle mods that many might miss, but will help the finished car look that much cooler. Note how the frame cover piece is built to flow toward and complement the fender. The Tanks, Inc. fuel tank has also been tucked closer to the body and the frame rails shortened and raised.

Back up front, there has also been a lot of attention paid to fitting the Rootlieb hood. This is Rootlieb’s Henry 25 Louver hood assembly that is one of the defining elements of the car. And while all the parts – body, hood, fenders, and grille shell – are high quality, anyone who has built an early Ford will tell you there are many hours involved in fitting everything together just right so the body lines, gaps, and panels all fit and flow well. The team also filled the cowl vent, since a Vintage Air system will be mounted under the cowl behind the dash.

Two more defining elements to the car’s aesthetic are the Deuce grille shell from United Pacific and the Rootlieb’s Henry 25 Louver hood assembly. It takes a lot more effort than most people realize to get these pieces fit, adjusted, and fine-tuned so that everything aligns well and the gaps are tight. This ultimately involved taking a 3/16-inch pie cut from the rear of the hood and 1/8-inch in front to fit the hood precisely to the body. It’s important to do that work now, in bare metal, so that the parts will go back together as intended when the car is painted.

Since there will be a Vintage Air climate control system mounted behind the dash, the Streamline team filed the cowl vent and smoothed the cowl for a clean appearance.

This mockup phase has also seen the fitting of other key elements, like the headlight bar from United Pacific (a 2-inch dropped unit that was lowered an additional 2-inches), and the headlights and grille insert from Speedway Motors. Look closely and you’ll also see that the Streamline team built a curved front spreader bar for the frame with a shape that flows better with the fenders, plus a custom valance built to fit around the grille and that’s rolled down to mirror the reveal line of the car.

Will leave you with one last teaser for now of the Goodguys Giveaway 1932 Ford. Things are starting to look very cool with the grille insert in place and the ’34 commercial headlights mounted on a modified headlight bar – a 2-inch dropped unit that has been lowered an additional 2-inches. Amber fog lights add a distinctive touch. Note also the curved spreader bar, which flows perfectly with the arcs of the front fenders, and the plus a custom valance under the grille shell.

All of these little mods and elements might be hard to pinpoint on the car when it’s finished, but they will all contribute to an overall look that’s clean, tight, and cool. And that’s exactly the appearance a high-quality hot rod should have.

Photos courtesy Streamline Custom Designs