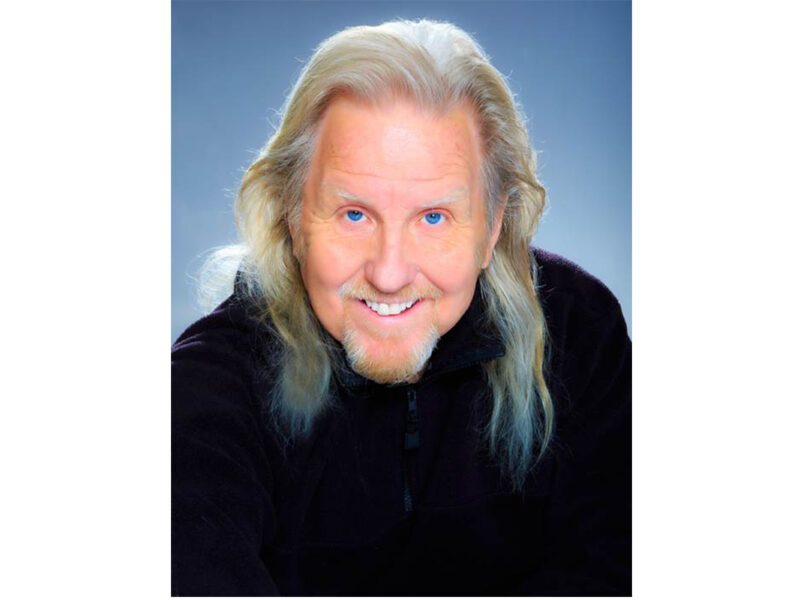

5 Minutes With Steve Tracy

Steve Tracy still recalls when he got turned onto hot rods in the mid-1970s.  “The guy across the street took me to the Frog Follies [street rod show] in Evansville [Indiana] when I was 14,” Steve says. “I went out there for the frog races, but when I saw the street rods, I threw the frog in the pond and never looked back.”

“The guy across the street took me to the Frog Follies [street rod show] in Evansville [Indiana] when I was 14,” Steve says. “I went out there for the frog races, but when I saw the street rods, I threw the frog in the pond and never looked back.”

Steve got into motorcycle racing in his 20s – flat track, road racing, and drag racing – and met some Nashville-area chrome shop owners during a Florida motorcycle event. Those relationships ultimately led Steve and his wife, Sheri, to Nashville, where they became partners in Advanced Plating. “I told my father I was moving to Nashville to plate people’s grille shells and door handles,” Steve says. “He thought I was absolutely crazy. ‘There’s no way you’re going to make a living plating hobbyists’ parts,’ he said. Little did he know what it would become.”

Since becoming sole owners of Advanced Plating in 1988, Steve and Sheri have built it into a premier plating business not only for vintage cars, but also the music industry, plating parts for many top guitar builders. “To work here, you have to be driven by the hot rod scene or into the music,” Steve says.

We took a few minutes to talk with Steve about cars, guitars, and the enduring allure of chrome.

Goodguys Gazette: What was your first car?

Steve Tracy: A 1969 Oldsmobile Cutlass. It was $350. I drove it home and got the JC Whitney catalog out – air shocks, shift kit, put a four barrel on it. Me and a friend worked on the thing all the time.

GG: What cool cars do you have in your current collection?

Tracy: I have a 1940 Chevrolet convertible – the first car Sheri and I bought together as a couple. We’ve had that car for 33 years. It’s on its third life. I’ve also got a ’40 Cadillac Series 62, a big four door. I drive it on the Goodguys AutoCross course – kinda looks like the Titanic driving through there. My most recent projects are two Novas – a ’64 and a ’67.

Photo by Tim Sutton

GG: You’ve had setbacks through the years, including the devastating 2018 fire resulting in a total loss of your Nashville production facility. Some might have walked away after that – why were you driven to rebuild?

Tracy: I didn’t want to exit the industry on a low. I had a lot of people offering help, which was very humbling – people saying, “you can’t quit – where am I going to go?” I also have a lot of employees who have been here 25-30 years. The reason we are where we’re at is because of those people. I felt like we owed it to them.

GG: Is there a guiding business principle that has served Advanced Plating through the years?

Tracy: The whole thing is based off of quality, service, and delivery. It doesn’t matter if a guy comes in here with his ’34 Ford grille or his ’79 Oldsmobile 98 bumper, there’s sentimental value tied to both of those. I’ve always just done the best possible job on everything.

GG: You’ve been involved in both a roadster and a lakester raced at Bonneville. What draws you to land speed racing?

Tracy: It was really just the need for speed. It’s a total release. When I get behind the wheel of that roadster or slip into that lakester, I am not thinking about the plating shop anymore. It’s just so invigorating driving this roadster at 220mph.

GG: What’s the biggest change you’ve seen in the old car hobby in recent years?

Tracy: The move from the pre-’48 into ’60s and ’70s muscle cars. And the popularity of trucks is almost hard to describe.

GG: Besides traditional shiny chrome, what plating finishes are custom builders seeking these days?

Tracy: We’re seeing a resurgence in black chrome – we have two new black chromes. And brushed finishes. We actually have the capability to do two or three finishes on the same part; you can have a part that has a satin, brushed, and bright finish on it. It adds contrast.”

GG: What’s the most misunderstood aspect of the plating process?

Tracy: The amount of labor in polishing. People still think that we just put it on a wire and dip it. We restore metal here, that’s really what we do. It’s an art form, just like the fabricators at these hot rod shops.

GG: Advanced Plating does a lot of plating for guitar and banjo manufacturers. What’s your favorite part of being involved with the music industry?

Tracy: I really like to develop hardware for electric guitars. We have a dozen patents on electric guitar hardware. What I have learned through the hot rod industry, I have put it into the hardware of these guitars. It’s allowed a lot of improvement in the music industry.”

GG: Based on the parts you see coming in, what trends do you see coming down the road in the old car hobby?

Tracy: So many shops are making components out of aluminum because it seems like they all have HAAS [machining] equipment. The capability to dream up a part, make the drawing, machine it, and send it here to be plated just continues to add individuality to the hobby. We’re pretty heavy into ’60s cars in here right now. Big stuff – Cadillacs, Buicks. I’m seeing a lot of off-the-beaten path models – people are pulling them out and making them into really cool rides.

GG: How do you respond when you hear the phrase “chrome won’t get you home?”

Tracy: It just makes you a lot more popular.