Shane Wright’s Deuce Roadster by Adams Hot Rod Shop

The role of a car builder goes well beyond fabrication and assembling parts. A good builder must also serve as a project manager, design consultant, and, sometimes most importantly, a motivator to the car owner.

Chad Adams of Adams Hot Rod Shop fulfilled all those roles on Shane Wright’s ’32 Ford highboy roadster, a car that took three decades of planning and just nine months to finish.

“I’ve been buying parts since 1991 to build this car,” Shane says. “I did some work through the years, and then got out of rodding for a bit. My dad passed away three years ago. I knew Chad and called him about another car. He asked if I still had the ’32 parts and said he would build it for me, so here we are.”

Deuce hot rods are familiar territory for Adams, so he was able to make quick work of modifying the frame and assembling it with a dropped and drilled Super Bell axle, Pete & Jakes hairpins, and a triangulated four-bar rear suspension. Disc front brakes (hidden in Buick-style drums) and rear drums were assembled behind 16×4- and 16×6-inch Wheelsmith steel wheels wrapped in Firestone bias ply rubber.

Neither Shane nor Chad felt the need to do anything exotic for power, so a reliable and strong 350c.i. Chevy small block was set up in the chassis and backed by a TH350 transmission. A Holley carb handles fuel metering, block-hugger headers expel fumes, and everything is nicely detailed and painted gloss black.

The Brookville steel body received the requisite fitting and fine tuning to achieve uniform gaps and precise panel alignment. Chad and Shane then agreed on a vintage-style beige hue called Classic Clay that was applied using PPG materials. A heavily raked windshield, commercial headlights, and ’37 Ford taillights helped finish off the exterior.

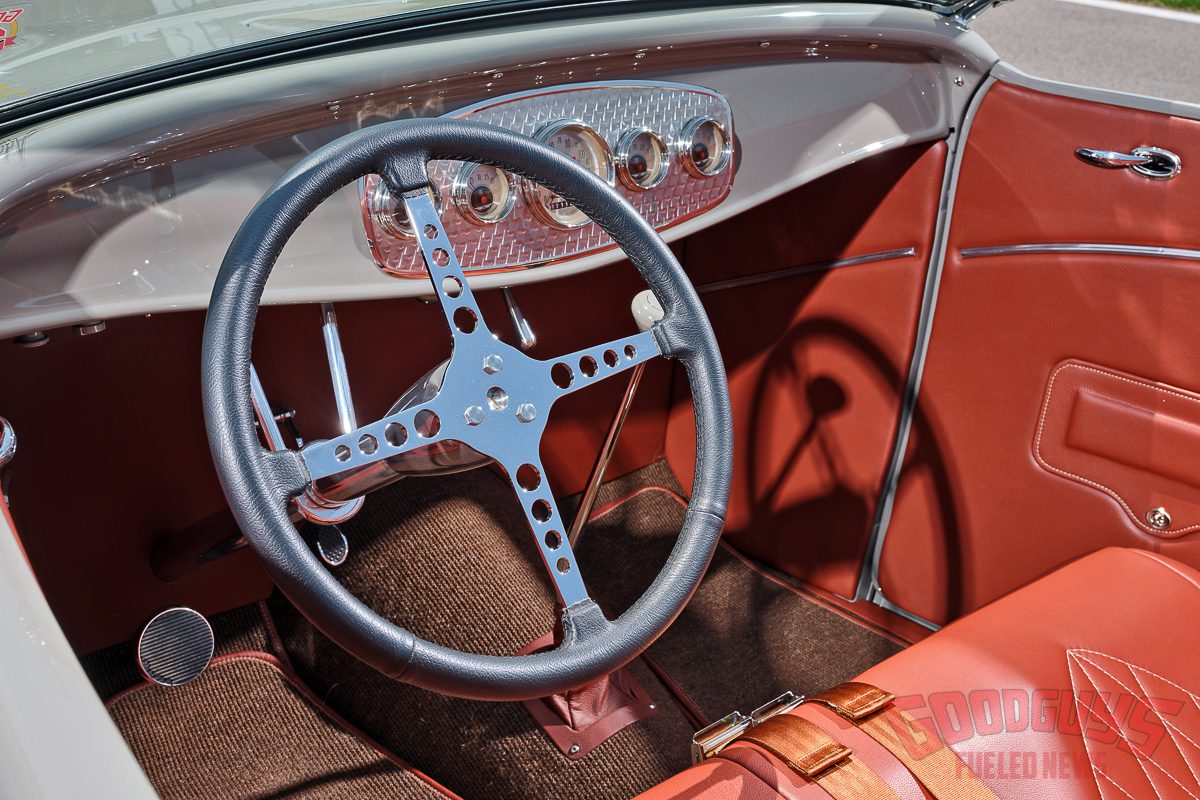

One benefit to Adams Hot Rod Shop is that upholstery work can be done right there without leaving the shop. On Shane’s roadster, this included brown leather upholstery with diamond-stitched inserts over a custom bench seat, with simple side panels upholstered to match and adorned with trim. Classic Instruments were used to fill the engine-turned dash panel, a drilled four-spoke steering wheel was bolted atop a stainless steering column, and a Lokar shifter helped finish things off.

Shane says that making the decision to pull the trigger and turn the build over to Chad was the most challenging part of the project. Once it was at the shop, things went smoothly. The results speak for themselves and serve as a good reminder of how beneficial it can be to have a good builder guiding your project.

Photos by John Jackson