Roadster Shop Tour – Metal Magic in Mundelein

A Roadster Shop Tour is something all car guys and girls should put on their bucket list. This place is unbelievable.

Roadster Shop is a household name in hi-performance hot rods, muscle cars and trucks. The chassis engineered and built by this Illinois-based business are found under some of the top hot rod builds in the country. Beyond those chassis, Roadster Shop has also been responsible for crafting some of the most sophisticated, trendsetting muscle cars, rods and custom trucks over the past decade or more. Much more than roadsters, Roadster Shop, RS if you will, has evolved with the hot rodding industry and now helps guide its trends, turning out both chassis and vehicles with ultra-low stances, great handling, bold style and tons of power.

Roadster Shop’s name is a reflection of its origins. Founded in Elgin, Illinois by Bill O’Rourke in the 1980s, the shop’s primary focus was building quality chassis for prewar Fords, with a handful of complete street rod builds sprinkled in. Jeremy Gerber was a young employee at the shop, cutting his teeth on hot rod building after growing up around his father’s body shop businesses. When O’Rourke was diagnosed with an aggressive cancer in 2004, Gerber teamed up with his brother, Phil, and father, Neal, to purchase the business. The Gerber’s hoped to maintain the shop’s legacy of building top-quality chassis and cars, while also expanding its scope to better serve the direction in which they saw the industry growing.

Under the Gerber family’s guidance, Roadster Shop has grown exponentially in both size and scope over the past decade and a half. The business first expanded its chassis offerings, branching out into broader markets like Tri-five Chevys and classic trucks. After building a few custom vehicles to prove what they could do in that arena, the shop also began attracting complete builds. Before long, the business had developed a reputation for top-quality craftsmanship and design, both in manufacturing and in car building.

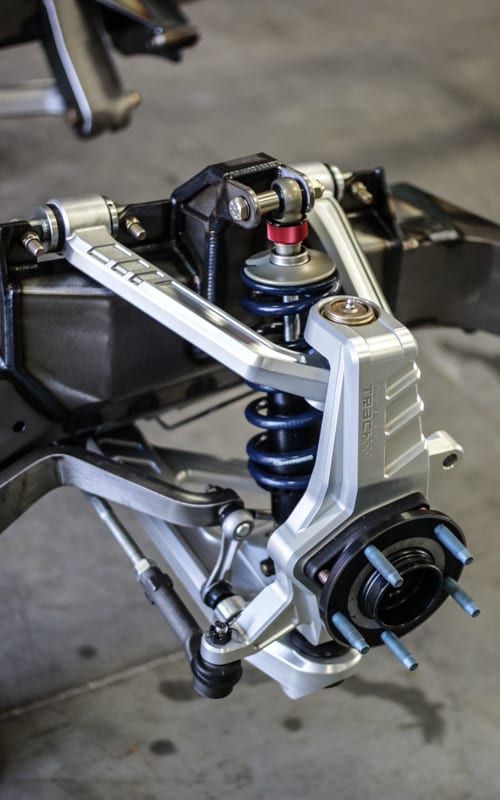

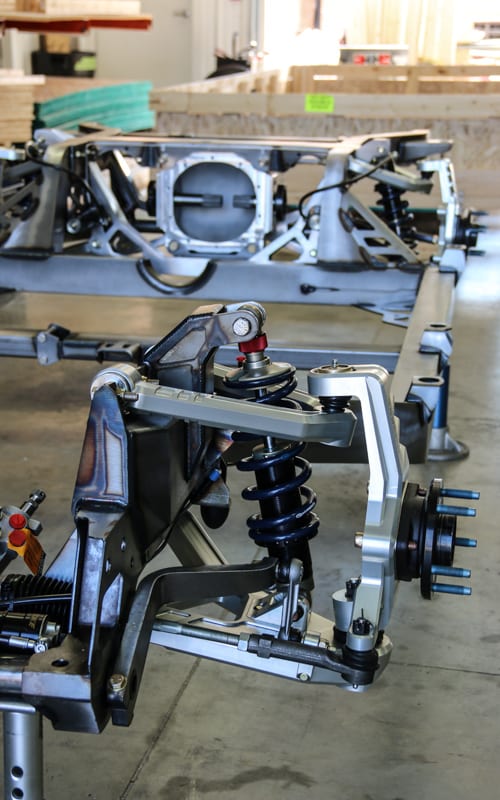

Today, Roadster Shop sells hundreds of custom frames and suspension systems every year. The shop’s REVO, Fast Track and SPEC Series chassis are available for just about any type of vintage car or truck, from prewar Fords to ’70s and ’80s trucks. The car building side of the business, meanwhile, routinely turns out some of the most innovative, award-winning and trendsetting custom cars and trucks in the hot rod scene. It’s one of the true elite coachbuilding enterprises in the country, pushing the envelope in style, craftsmanship and construction. That’s the portion of the business we’ll focus on.

The sprawling facility gives Roadster Shop the space necessary to provide devoted areas for every step of a vehicle build. There’s an upscale 5,000sq. ft. showroom to greet customers and potential clients, as well as show off completed builds.

There are separate areas for metal fabrication, construction, and mechanical work, plus a dedicated paint and body department with a downdraft spray booth. A clean assembly area keeps the final portion of the build process away from potential hazards. Of course, having in-house design, engineering, machining and modeling capabilities simply adds to the abilities and creative ideas Roadster Shop can incorporate into a custom vehicle.

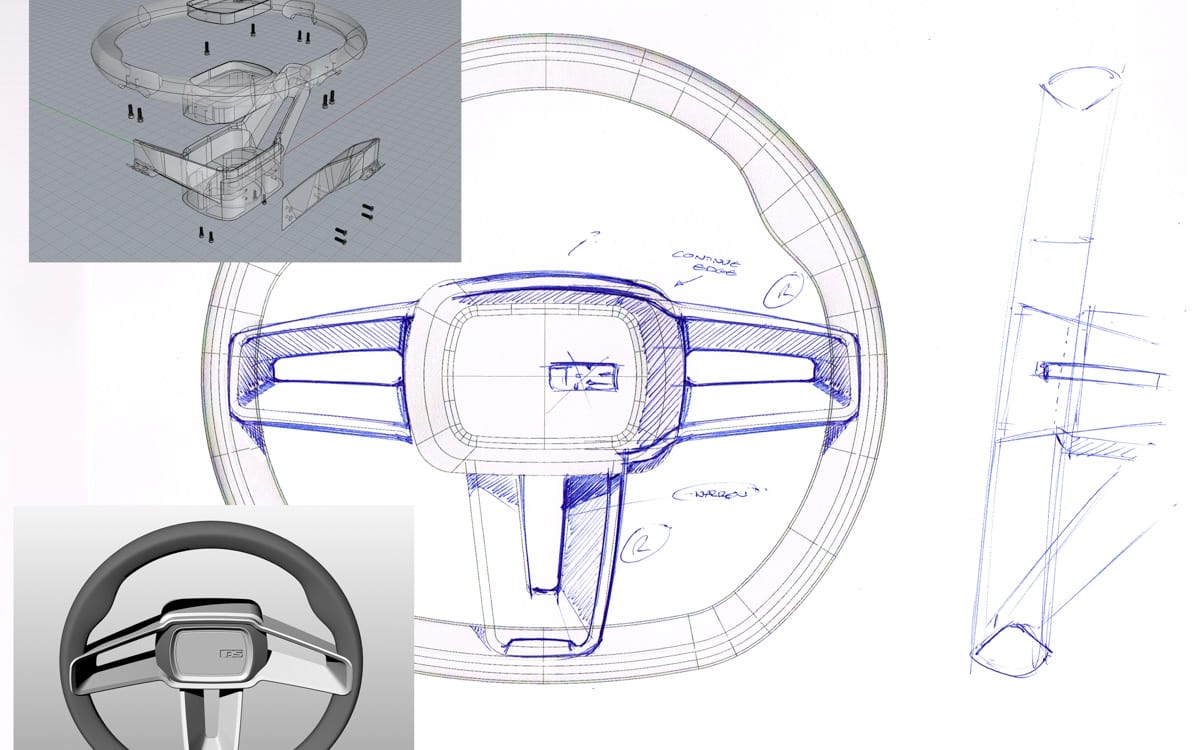

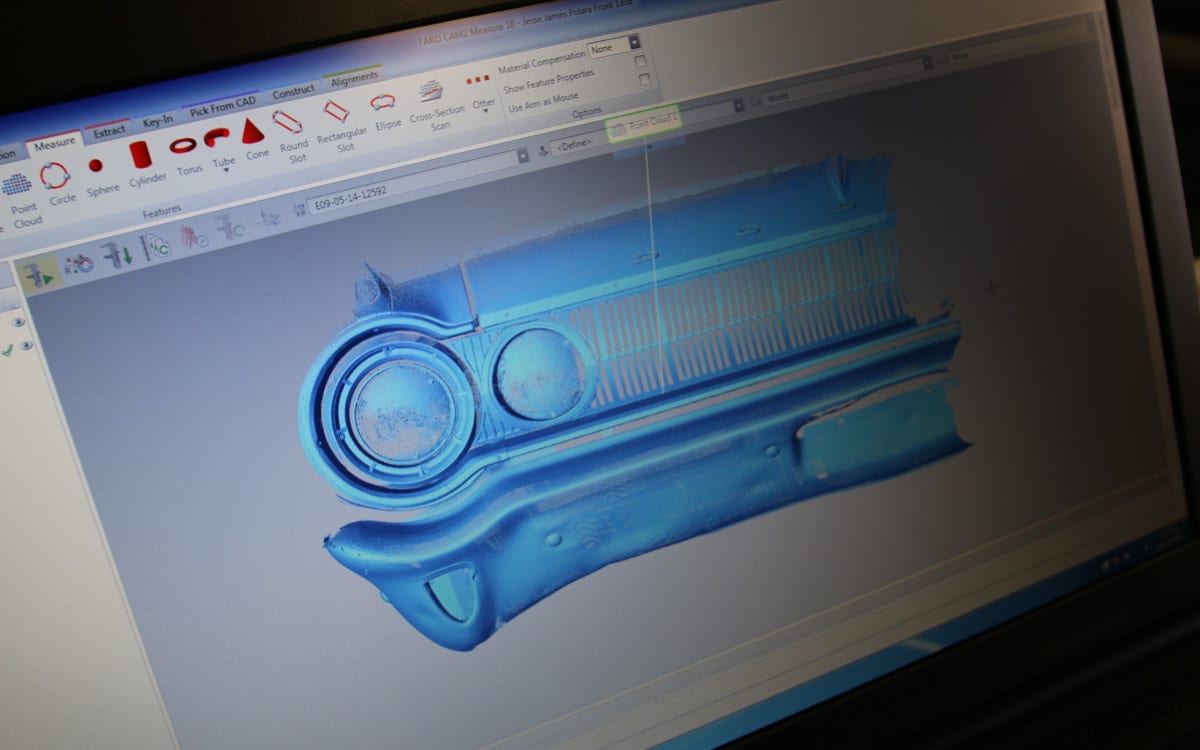

The Roadster Shop team learned to take a comprehensive, big-picture approach to its builds early on. After consulting with customers on the goal for a vehicle, an in-house design department conceptualizes the finished product before the shop starts any work. Today, that process might also involve a 3D scan of the vehicle, which allows a digital rendering to be developed on the computer. This scan can then be manipulated to visualize changes, design custom components and virtually model parts – everything from a one-of frame, to custom brackets, body panels, interior components and other details.

These forward-thinking approaches and capabilities have set Roadster Shop builds apart from others and have established the shop as a leader in performance and design. Need examples? How about the custom 3D-printed interior switches and side mirrors on John Wilkus’ ’69 Camaro, which was the Goodguys 2017 Street Machine of the Year. Or the steering wheel for the same car, which was computer designed and then machined from four pieces of aluminum. The car’s taillight housings were also computer designed, custom machined and fitted with 3D-printed internals with LEDs to illuminate the one-off machined acrylic lenses. Such innovations and clean-sheet design processes often lend a concept-car quality to Roadster Shop builds.

An impressive facility and high-tech capabilities are great, but it’s equally important to have a talented team to back those tools up with quality craftsmanship. Roadster Shop excels in that regard, too. The shop employs about 60 people, with roughly a third of those dedicated to the hot rod building portion of the business. From metal shaping, to fabrication, to final fit and flawless paint, the shop’s craftsmen have developed a strong reputation for top-quality work. That work, in turn, has resulted in a string of influential, award-winning vehicles.

In 2009, Barry Blomquist’s Roadster Shop-built C1RS ’62 Corvette won the Goodguys Street Machine of the Year title. The bold Vette, designed by Eric Brockmeyer, incorporated European influences and competition design cues ranging from the projector-style headlights in custom-machined housings, to the carbon fiber vents in the side coves, to a diffuser panel in the rear pan. With an RS chassis, Forgeline spindle-mount wheels and LS7 power, it not only looked potent, it out-performed every other SMOY candidate on the AutoCross course. The car won a GM design award that year at SEMA, while Jeremy and Phil Gerber won the Goodguys Trendsetter Award. The finished product mirrored Eric Brockmeyer’s

Two years later, the shop struck again with Alex Covington’s Innovator ’67 Nova, a radical, forward-thinking millennial take on classic muscle that won Goodguys 2011 Street Machine if the Year. It featured an extensive array of bold, custom-fabricated design updates, including a handmade grille insert, headlight and taillight bezels and hood vents, among myriad other body mods. Spindle-mount wheels on a RS Fast Track chassis with a 700hp LSX engine made it a performer.

Roadster Shop’s builds continued to get more elaborate and exotic as the team mastered new techniques and approaches, resulting in one of the shop’s most elaborate builds in 2014 – the Rampage ’70 Camaro. Radical carbon fiber fenders, flares and spoilers combined with an incredibly low stance, a cantilevered independent rear suspension, and a 750hp LS7 with carbon fiber crossram injection to make this competition-style Camaro a true beast. It topped the 2014 Gran Turismo Awards at that year’s SEMA Show, resulting in the car being immortalized in video game fame.

You get the picture. Roadster Shop vehicles have been finalists for many Goodguys Top 12 awards, in addition to winning three Goodguys Street Machine of the Year honors. The latest SMOY win came just last year, with John Wilkus’ incredible Inferno ’69 Camaro. While the look of Wilkus’ car is not as overtly radical as the Rampage Camaro or Innovator Nova, it arguably has as many modifications and custom-fabricated components – they are just subtler in nature. The shop’s style seems to be refining.

Not all Roadster Shop builds feature elaborate body restyling, though. The patina’d ’64 Dodge Polara the shop recently built for Jesse James – set on a RS chassis with a twin-turbo Hemi – was one of the highest-profile builds at the 2017 SEMA Show. The shop has also built several resto-mod drivers for collector George Poteet, outfitting low-mileage original cars with updated chassis and drivetrains suited for long-distance cruising. Known as the Survivor Series, these vehicles combine the character of well-preserved paint and trim with the best modern performance available.

In addition to receiving awards, Roadster Shop also gives them. The shop has teamed up with Goodguys to sponsor the Roadster Shop Style & Engineering Award given out at select Goodguys events throughout the season. Each event winner becomes a finalist for the end-of-year Style & Engineering title, an honor that includes a new Roadster Shop frame. Take a look at the beginning of those frames. They start as flat sheet then get run through a state of the art Plasma Cutter before being produced.

After nearly a decade and a half of growth, there’s no indication Roaster Shop is resting on its laurels. The company continues to bring new offerings to market, like chassis for Squarebody pickups and next-generation performers like third-gen Camaros and Foxbody Mustangs (the Goodguys ’79 Pace Car Mustang rides on a Roadster Shop Fast Track chassis).

They are also now offering cutting edge chassis for early Ford Broncos which resemble jewelry!

Based on the shop’s most recent builds, it appears the bar will just keep getting higher, with creative and innovative new approaches and techniques allowing the shop to continually reinvent some of hot rodding’s favorite vintage platforms.

Beyond quality builds and products, Roadster Shop does a tremendous job of connecting with customers and enthusiasts through its presence at events and a strong following on social media platforms like Facebook and Instagram. The shop’s website is a great resource, too, with extensive photo galleries documenting most of their builds. This documentation provides an educational inside look into the processes and details that go into these builds. It’s a treasure trove of information for anyone interested in the construction process of today’s top-tier custom creations.

Much more than roadsters, Roadster Shop’s multi-faceted approach to business and dedication to quality and innovation epitomizes the breadth and variety of today’s hot rodding scene. From survivors to show-stoppers, early Fords to next-generation muscle, the shop covers it all. Every time we think everything that can be done in hot rodding has already been done, Roadster Shop seems to prove us wrong. We’re looking forward to more pleasant surprises for years to come.