Metal Brothers Hot Rods Built One Bitchin IROC Camaro

Everyone has that one cool aunt, the one who likes your music, relates to you more like a friend, and is just fun to hang out or chat with. For Francisco Murillo, Aunt Betty was his cool aunt partially because she drove a third-gen Camaro and would take him out cruising now and then (it helped that she was only five years his senior). The seat time left a Francisco with a desire for a third-gen, preferably an IROC.

When Francisco got his driver’s license, he found a fourth-gen Camaro, which was still a cool cruise for high school, but Aunt Betty’s third gen still stayed planted on his wish list of cars to own someday. Alas, that vision would have to wait as he set out to start a career building hot rods and eventually formed Metal Brothers Hot Rods, based in southeastern Alabama.

Even while running a company and building hot rods and muscle machines for customers, the thought of a third-gen Camaro continued to burn in Francisco. He finally found a worthy candidate that already had an LS swap, but a deluge of rain combined with sketchy road conditions put an abrupt end to that car. Francisco was not deterred, though. Not long after he found an ad online for an ’88 IROC that was solid, complete, and priced right. The deal was made, and it was time for Francisco to build himself a nice daily driver that was reliable and fun to cruise.

As you can see, the project went a little further than “a nice daily driver.”

There was one thing about his new car that Francisco wasn’t crazy about: it had T-tops. Back in the day, that was the only way to roll but when your plan calls for serious power in a car that can start, stop, and turn on a dime, a full-roof coupe is the best choice. To solve this dilemma, a hard top roof was sourced and installed. When your company is called Metal Brothers, you don’t shy away from a little sheet metal labor!

The rest of the Camaro body was kept largely stock though the gaps were tightened, panels made razor straight, and even the plastic bumpers were smoothed. Francisco did extend the front facia a bit before laying down a Wolf Gray shade of Axalta’s Chromax XP paint highlighted with a custom set of IROC-Z decals and emblems.

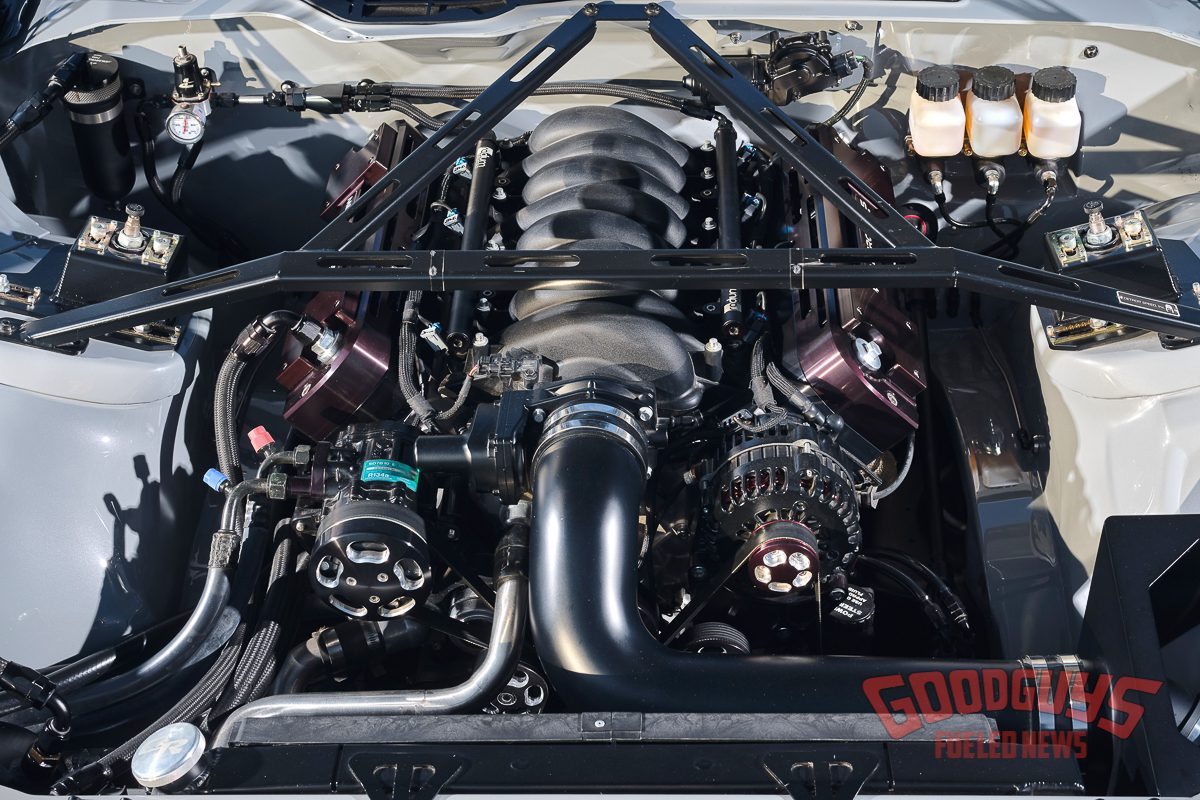

To remove the inherent unibody flex and strengthen the entire vehicle, a complete Detroit Speed front subframe was installed including control arms, springs, beefy sway bar, and JRi double-adjustable shocks. The stern also received an upgrade with a complete DSE Quadralink kit with a 9-inch Ford rearend, Moser axles, and a set of 14-inch Wilwood rotors and calipers. Forgeline 18×10- and 18×11-inch wheels, reminiscent of the original IROC style, are wrapped in BFG Rival tread for comfort with serious grip on the pavement.

To add yet another layer of structural integrity combined with safety, a four-point roll bar was installed with a set of Team Tech harnesses and Sparco seats. The gauges were updated with Dakota Digital instruments that are wired into an American Autowire harness. The door panels were left stock, a new Wooward steering column was added and topped with an MPI steering wheel, and a RestoMod A/C system keeps the cabin cool.

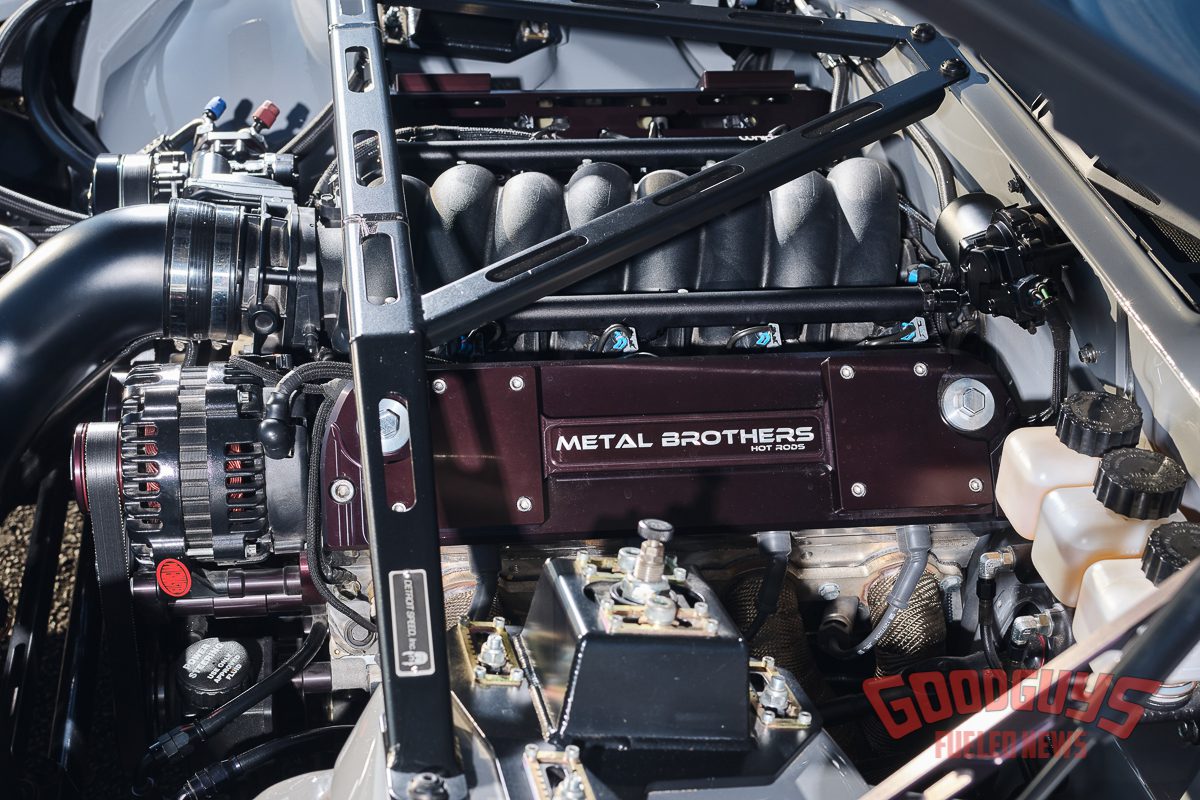

Once strapped in, Francisco reaches for the shifter to control a Bowler-built Magnum T56 coupled through a McLeod dual disc assembly that is tied to a wicked LS engine which was painstakingly moved back 5-inches to improve weight distribution. The custom-built 416c.i. LS3 is built to spin up to 7,000 rpm thanks to a beefed up valvetrain and rotating assembly. An Aeromotive fuel system feeds the 93-octane while a set of Hooker Blackheart headers leads to a 3-inch custom exhaust and Stainless Works mufflers. Listening to the car roll by is intimidating enough and even more so at full song on the highway.

The IROC Camaro ended up taking about three years to complete, a little longer than anticipated, and with a touch more power, performance, and labor than originally planned. But that’s how projects roll in the hot rod hobby and industry. Next up is to get behind the wheel and get it out on a track. It’s safe to say Aunt Betty would approve!

Photos by John Jackson