Lethal Appeal – Killer Hot Rods Builds a Winning Reputation in the Heart of Texas

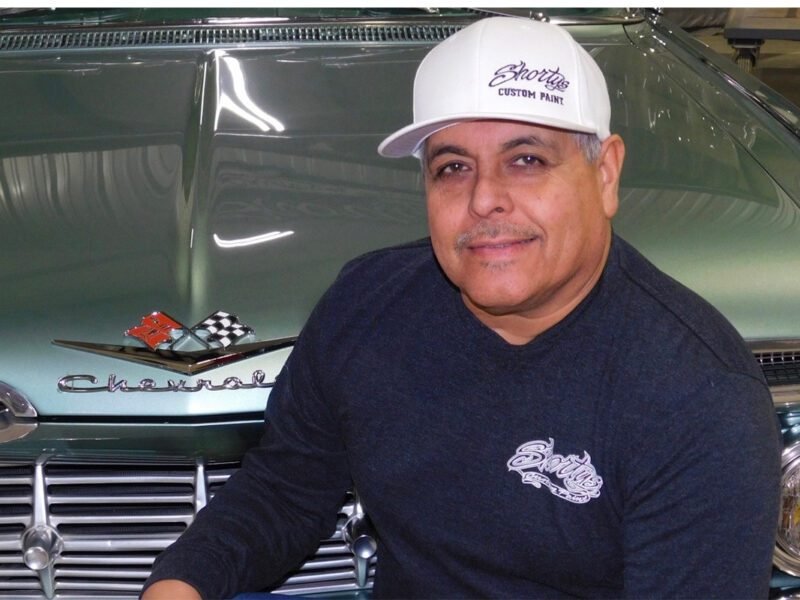

Learning on the job teaches more than just basic skills. Those experiences – good and bad – are often the inspiration to make the leap from employee to business owner. For Kevin Penhaker and Nick Ryan at Killer Hot Rods & Customs in Alvarado, Texas, that choice came after years of living through too many lessons on how not to run a shop.

“We were working at a shop before that wasn’t very well managed,” Kevin says. “That motivated us to start our own.”

Ten years later, Killer Hot Rods has a record of producing outstanding rides for a steadily growing customer base. A waiting list of 18 to 24 months confirms that Kevin and Nick are applying the lessons they learned.

The pair concentrated on full builds from the start. Two customers followed them from their previous employer because their projects were languishing. “We told them we were going to be starting our own business,” Kevin says. “Their cars were sitting in the other shop; no work being done.”

Creative Marketing

Two projects, though, would keep them busy for only so long. They knew that building the business would need to be a priority. They devised a creative plan to promote the shop: build a car to display their skills. But as is the case in most startup ventures, creating a high-level car without a customer to foot the bill would be almost impossible. Kevin and Nick had an idea, though. They found a few investors to put $100,000 into the build.

“The agreement was that we would keep the car for a year and show it off to show the quality of our work,” Kevin says. “Then we’d sell the car at auction, give them their money and the profit.”

Building a car without a customer allowed them to build the car – a ’70 Dodge Challenger – the way they wanted. The lime green street machine sported an upgraded suspension and a Hemi crate motor, among other features. “Everybody really appreciated it, and it brought in a couple of other jobs,” Kevin says. “Of course, the more cars you put out there, the more people see your work. Without having a customer base and cars out there, this was the only way to do it.”

Thriving Off a Good Start

That creative marketing defined today’s Killer Hot Rods, allowing the shop to specialize primarily in full builds. With the exception of interior work, the team does all the other tasks of its custom builds in a new 12,000 sq. ft. building. The crew works on a variety of vehicles. While most projects are hot rods and customs, restorations, including a relatively rare 1929 Dodge Brothers sedan, are also on the menu.

That build was unusual, but it was another opportunity to display the shop’s versatility. “It was so far out of the norm,” Kevin says. “A learning experience that I really enjoyed.”

With 14 projects underway currently, working with customers to assure a successful build is critical for Kevin and Nick. Like many shops, a potential customer often comes into Killer Hot Rods with an unfinished project that was started at another shop.

Kevin says many of those incomplete projects come from shops that quote unrealistic low prices for the quality of build the customer wants. They give a price that doesn’t allow for the many surprises that often emerge during any project.

“We don’t give quotes,” Kevin says. “It’s this much per hour and however many hours it takes, that’s how much it’s going to cost. If they’re not OK with that, we’re not going to do business with them.”

Rendering Guidance

Once the shop commits to taking on a project, the next step is working with the customer to develop the design. “We require customers to have a rendering made so we have a visual of the finished project, so there’s no confusion,” Kevin says. They work with two artists, one who develops the exterior renderings and another who does the engine bay. The artists usually do two or three renderings to give different looks for the customer. That nails things down, Kevin says.

A recently acquired 3D printer helps create unique pieces to enhance custom builds, Kevin says. Also, the ability to create a prototype in plastic to make sure a part fits and looks correct before sending it to the CNC machinists saves time and money.

Keeping up with changing trends is challenging for any shop, but the success Killer Hot Rods has had allows Kevin and Nick to focus more on working with clients, both repeat customers and new ones who are attracted to the shop’s work.

Feeling Validated

“Repeat customers are a validation for us,” Kevin says. “That tells we we’re doing something right.”

Doing something right means that some customers might bring in a car that requires a year to restore the metal before any customization actually occurs, while others walk in the door empty handed, except for an idea. “We’ve had customers who don’t have a car,” Kevin says. “They tell us what they want, and we go find it. They trust our work; they trust our judgment.”

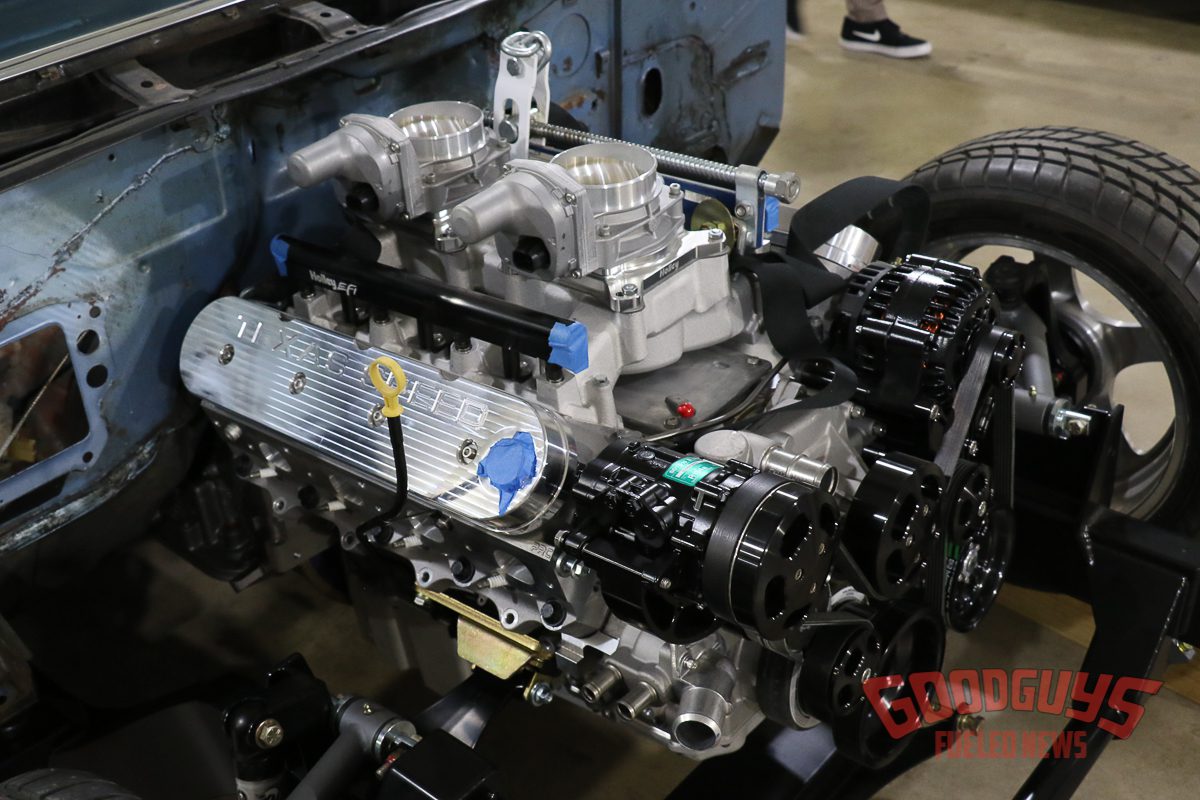

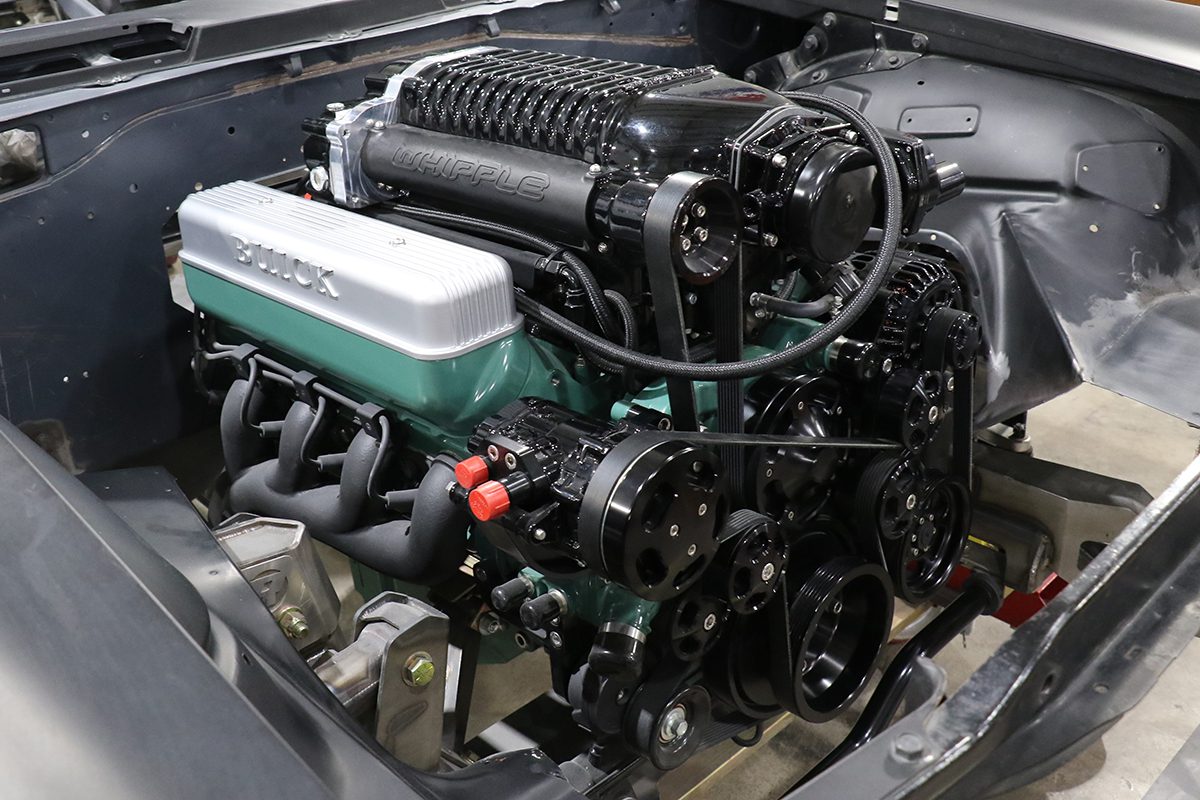

The cars in the shop today reflect the different views of their customers. In addition to obvious projects like vintage muscle cars and trucks, you’ll see a ’59 Cadillac and a mid-’60s Buick Riviera. Both are receiving powertrain and chassis upgrades.

Not surprisingly, many customers want their projects to have a vintage look, but modern performance and comfort, Kevin says. That often means powertrain and chassis upgrades along with improved electronics.

Finding Killer Help

Kevin and Nick face a similar problem that plagues most shops with a growing customer base – lack of skilled job candidates. They’d like more employees because they have so much work, but finding good candidates is near impossible. “The people who can do this aren’t sitting at home on a couch, waiting for a phone call,” Kevin says. “They’re applying their skills and getting well paid.”

Kevin and Nick aren’t complaining, though. With a long waiting list of customers, needing to add workers is a good problem to have.

Photos by John Jackson, Damon Lee