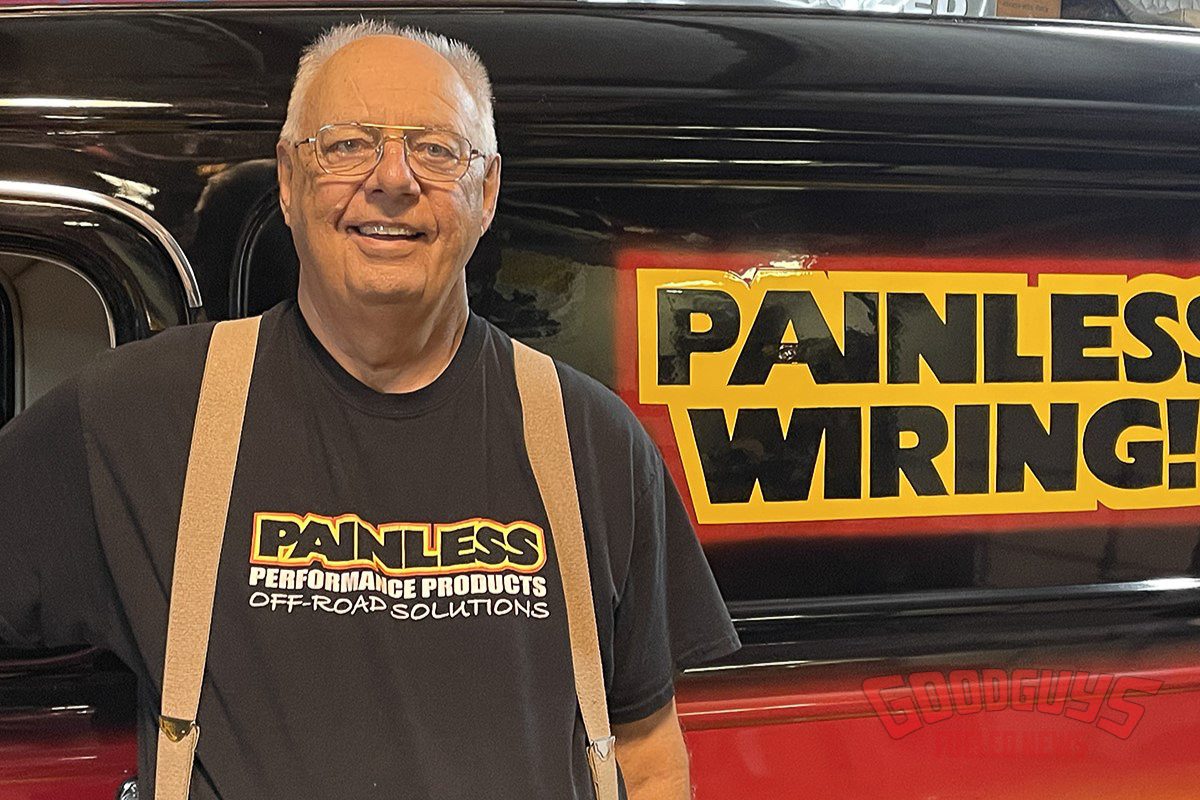

5-Minutes with Dennis Overholser of Painless Performance

If you’ve attended any major hot rod events in the last three decades, chances are you’ve seen or maybe even talked with Dennis Overholser. You’ll often find him giving a tech seminar about wiring or see him working the Painless Performance booth, the company he founded back in 1990.

A lot has changed for Dennis over the years since he built his first wiring harness and deciding to quit a secure job at a tractor dealer. It proved to be a successful move, though, and hot rodding continues to be the common denominator for Dennis as a business owner and enthusiast. He was a hot rodder first, and still enjoys going to shows, talking to customers, and helping fellow rodders with their wiring and electrical questions. Dennis has been on the Board of Directors with SEMA and has volunteered his time the Hot Rod Industry Alliance (HRIA) and Motorsports Parts Manufacturers Council (MPMC). In fact, he’s in the HRIA Hall of Fame! Though he’s now semi-retired, Dennis still logs more miles and attends more shows than most – usually in the familiar Painless Performance ’36 Ford panel truck. We were lucky to catch five minutes of his time.

GG: How would you compare the hot rodding hobby of today, compared to 1990 when you founded Painless Wiring?

Dennis Overholser: I’d say the biggest difference is in the type of vehicles being built. Back in 1990, it was all street rods and muscle cars were there, but more in the background. Today it’s kind of opposite with muscle cars being the more prevalent choice these days. I believe the number of cars and people are about the same as back then, but muscle cars are more popular. I don’t think pre-’49 cars will ever go away, but the hay days are over. It’s a generational shift, just look at how popular trucks are with the younger guys now.

GG: What lead you to build a wiring harness back in those early days and did you think it would lead to a career?

GG: What lead you to build a wiring harness back in those early days and did you think it would lead to a career?

Overholser: I used to help friends wire their cars and just remember guys making an electrical panel out of a piece of wood and mounting it up under the dash. Not ideal, and always a hassle to get to and I just felt there had to be a better way. I finally assembled a fuse box with some wires and took three of them to the Pate Swap Meet in Texas and sold them right away. I built 10 more and took to the Street Rod Nationals in Columbus in 1990 and sold them all the first day. I quit my job at the tractor dealer that same year and started building the 18-circuit harness that is still sold at Painless today.

GG: We heard that you were semi-retired a few years ago, but we see you at shows all over the country still. Are you restless or still enjoy the shows?

Overholser: It’s really because of the people and that’s where all my friends are! I still enjoy the driving and still enjoy the shows, plus at this point, I get to pick and choose my favorites to attend. I also still enjoy giving tech seminars and working with our dealers. We’re building a good support and sales team at Painless so I may cut back on a couple more events, I’m thinking this might be my last Power Tour – I’ve done 23 of them!

GG: Speaking of being on the road, what is your favorite road trip destination – and what would you drive?

Overholser: I’ve traveled through all 50 states but my favorite place to drive or as a destination would be Colorado. I just love the mountains and don’t need to see another ocean or beach, just send me to the mountains. As for what I’d prefer to drive, pretty much any hot rod. The Painless ’36 Ford panel truck has more than 282,000 miles on it. I racked up 120,000 miles on our ’39 Chevy pulling a trailer and had a ’29 Model A sedan before that with plenty of miles. Send me to the mountains in a hot rod!

GG: What do you see as the biggest change in hot rodding over your career?

Overholser: The biggest change in hot rodding is in the performance and technologies being used on the builds today. The drivability and performance with EFI is so much nicer, more reliable, and delivers better economy. Painless made its first EFI harness in 1991 using a GM Throttle Body Injection system and that harness went on to be a hit, especially in the Jeep and rock crawling market. Of course, today it’s all about an LS and electronic transmission, but the technology continues to make other engine swaps easier too.

GG: What challenges lie ahead for future hot rodders or the industry?

Overholser: It is definitely legislation and government challenges ahead. They’ve already done things like cash for clunkers and pushing the auto industry more and more. I’ve been on the SEMA Board of Directors and subcommittees for the MPMC and HRIA and legislation is at the forefront of future challenges. I’ve also done several of the SEMA trips to Washington, DC – it is a good thing SEMA has offices and people involved to keep the industry up to date on these matters.

GG: As a hot rod enthusiast, what are some of your latest projects in the garage?

Overholser: Right now, it’s nice to say that most of my projects are running and driving! I have a ’66 Chevy II, I’ve had seven now, but this one is set up as a gasser wagon with an LS engine and an eight-stack EFI setup that is a blast to drive, and a ’73 C30 flatbed with its original 454 and now a 4L80E trans to make it a little more drivable around town for work. The Painless ’36 is getting some updates so it will be ready for the road and I’m helping a couple friends with their projects.