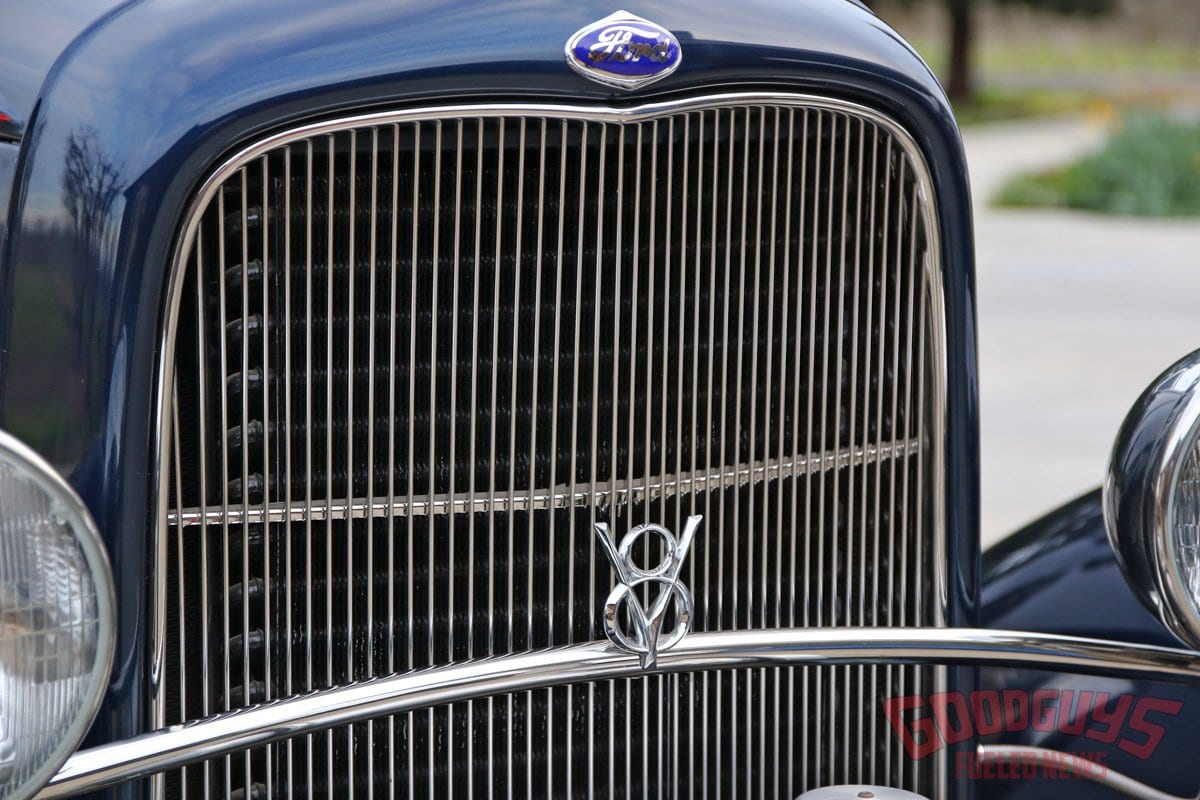

ARDUN Adventure – A Pair of Rare Heads Led Mike Michels to Build This Deuce Tudor

Words by Mike Michels

I was born into what I call the Golden Age. By the time I was a teenager, hot rodding was just getting started in this area of California, plus the birth of rock ’n roll, cruisin’, and drag strips. At 14, I had my driver’s license and bought a five-year-old ’49 Ford convertible. I paid $125, money earned by working on farms driving tractors, irrigating, shoveling out barns, whatever I could do for a buck.

I have this scene embedded in my brain of a certain blue ’32 Tudor driving slowly down the edge of the Kingdon drag strip with the door open sweeping the spectators back before another run. Another scene is a burgundy ’32 five window driving around Stockton Junior College. While going to college in Fresno in 1968, I bought a ’32 five-window coupe. It may have been the best investment I ever made, but at the time I thought $375 was too much.

It seems like things just fell into place with this Tudor. I already had a pair of original ARDUN heads and no thoughts of what to do with them. One day at a friend’s place there was a ’32 Tudor, dark primer, dropped axle, and as I passed by it whispered “ARDUN” to me. Love at first sight! I made the deal, drug it home, and assessed my foolishness. This turned out to be a 15-year project, mostly because I was in no big hurry, had some health problems, six other car projects, and the passing of my upholstery man.

The ARDUN heads that initiated the project were bought back in 2004. They’d been in storage for years and came with the rocker arm covers, rocker arms, Austin intake manifold, and many other parts. It’s likely they had been used in an Allard sports car back in the day.

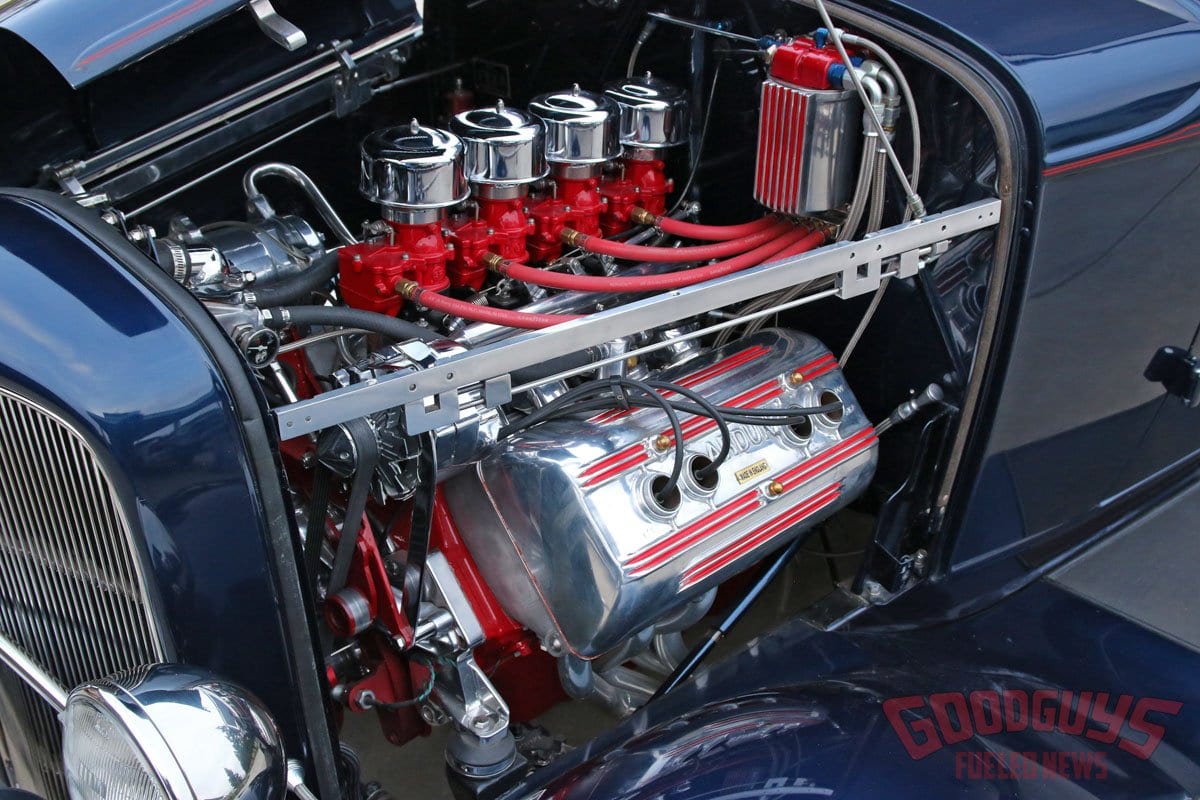

The engine came together in spurts over time and I could fill a book with the intricate details. Highlights include a ’49-’53 block, Mercury crank, Scat billet rods, Ross pistons, and a Howards cam with a Cotton Werksman grind. B&R Automotive did the final assembly, and I used a Cornhusker Rod & Custom adapter for the polished Chevy 409 water pump. Manley valves and titanium retainers were used in the heads, along with one-off billet steel roller-tip rocker arms from T&D Machine.

Dan Fodge drilled and installed bungs into the intake manifold and machined the fuel rails for the planned electronic fuel injection. We used gutted and modified Stromberg carbs for throttle bodies and FAST XFI electronics from Imagine Injection to control everything, along with an MSD crank-trigger ignition. Tuning is accomplished by plugging our laptop into the FAST ECU and using the wifi from my wife Catie’s iPhone as I call Bob Ream at Imagine injection, who can make adjustments from his office in Arizona.

- Underneath ARDUN valve covers

A T5 five-speed transmission is connected using a Speedway Motors adapter. Danny Freitas fabricated the custom headers, which were Cermakrome coated by Cap’s Coatings.

The car’s frame started with lengthened and boxed ASC rails and a Chassis Engineering X-member. The Halibrand V8 quick-change is positioned by a long four-bar with Aldan coil-overs and has a TruTrac differential, Moser axles, and Buick fined aluminum brakes. The ’32 front axle has been dropped and I drilled the holes and had it plated. It’s located with split wishbones, rides on a Durant leaf spring, and has Super Bell disc brakes. Wheels are 15×7-inch Halibrand Smoothies in the rear and 15×5.5-inch American Rebel Gassers in front.

Sand blasting the body revealed a real horror: the lower 6-inches was totally rusted out. Don Brazil used Brookville roadster subrails as a starting point, lengthening them in the doors. A combination of other Brookville panels, hand-fabricated pieces, and Bitchin’ Products floors was used to replace the remaining rusty metal, and Don welded up over 100 holes where a sheet metal top insert was previously screwed down.

Guy Rouchenet then took over, tuned up the gaps, lengthened the front fenders, bobbed the rears, fabricated frame horn covers, and refined the Rootleib hood sides to clear the valve covers. Larry Westervelt punched the louvers in the hood top and kick panels. I painted the car using PPG basecoat / clearcoat Midnight Blue. Considering that I’m an amateur painter and painted it in my barn, I think it turned out good. Herb Mantinez laid down the pinstripes and I installed King Bee headlights and Harley Davidson “Tombstone” taillights.

I had been working with Leon Jones on interior design concepts such as the smooth headliner and GM pickup bucket seats. Somewhere between the wrecking yard and home the seats got wider, so I narrowed the frames and Leon narrowed the foam. I had two oxblood and one navy blue hide custom tanned and dyed for the seats to match the vinyl. Then Leon passed. I was deeply saddened and lost all interest in the car.

After a couple years, I began looking for a new trimmer. My wife and I spent a year at car shows looking at upholstery jobs. By a stroke of luck, we found Louis Rojas right here in Stockton who would follow the concept of what had been done, but still add his creativity. The trimming came together beautifully.

I replaced all the interior wood and installed the new vinyl top insert, hiding the radio and Sirius satellite antennas underneath. A combination of Classic Instruments and Stewart Warner gauges fill an engine-turned dash panel and creature comforts include Old Air heat and A/C, plus cruise control. The Hurst shifter is topped with an old agate doorknob I found in our cherry orchard.

The car has yet to be driven much, but with an expected 300 horsepower it should be a blast. Throttle response is instantaneous. I have to give credit to my machinist, the late Bob Skibo, without whom this project couldn’t have happened. In fact, many of the people who helped with the build have now passed, but I’m sure they look down with a big smile every time this ARDUN fires up.

Photos by Steven Bunker