5-Minutes with Ed Moss of Total Cost Involved

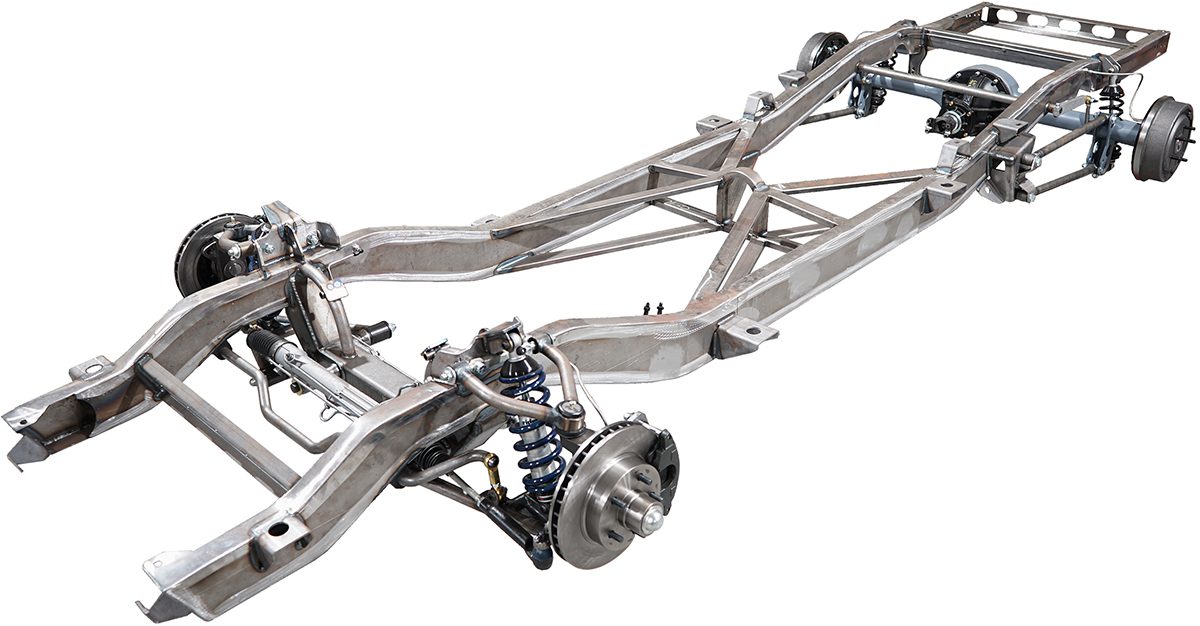

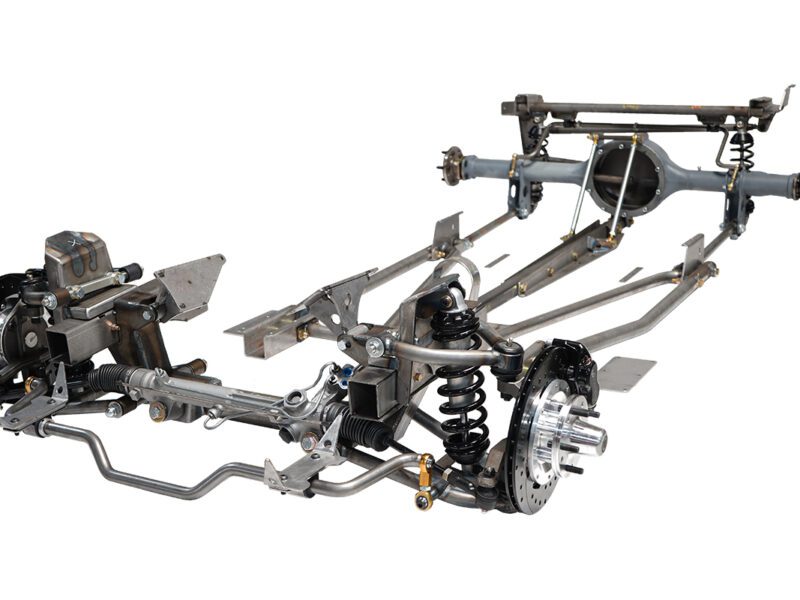

You may not initially recognize the name Ed Moss, but you certainly know the company he founded in 1974 as Total Cost Involved. This year marks TCI’s 50th anniversary and Ed is still going into their Ontario, California-based facility to design, fabricate, and tinker on chassis and suspension systems for hot rods, trucks, and muscle cars.

Ed started the company as mechanic who needed to fund his racing hobby and noticed the need for a stronger Model A chassis. Five decades later, TCI is still selling them along with complete chassis and suspension systems for many other hot rods, muscle cars, and vintage trucks. Few company founders are still involved or even working after 50 years, but Ed loves being in the R&D trenches and participating in the hot rodding industry. An American success story that grew from a passion for racing and hot rodding – congrats on 50 years!

GG: Congratulations on 50 years in business! Did you ever think you’d be manufacturing hot rod chassis in 2024?

Ed Moss: I never thought that far ahead! I was a mechanic at my father-in-law’s shop servicing transmissions and had started racing at the old Irwindale 605 Speedway. This necessitated extra funding, so I rented a small shop from my father-in-law and started working nights and weekends with my friend, Tom Medlock. I would take on everything from lowering lowriders to wiring and plumbing boats.

GG: What led you to build and market your first Model A frame?

GG: What led you to build and market your first Model A frame?

Moss: Back in the ’70s, T-Buckets were popular, so Tom and I started building them. We split after about a year, and he started Specialty Cars. I looked for a product I could specialize in and noticed there were lots of Model As with big V8s. The old frames would twist and flex under acceleration, so this was going to be my new product. I bought an original Model A frame for $40 and started making patterns. I still have that frame hanging in the R&D shop.

GG: What was the best advice you received while starting TCI?

Moss: The best advice came from Jim Ewing, from Super Bell Axle Company. I was building a dirt car to race at Ascot and it was taking up a stall in my 1,400 sq. ft. shop when Jim came in to deliver axles. He asked me what that car (he used another three-word description!) was doing there and I told him I wanted to continue racing. His advice was to sell the car and focus on only the business, with no outside distractions. So, I sold the car and used the money to buy a small flame cutter that helped the business.

GG: When did you think, “I can make a living doing this?”

Moss: Shortly after selling my race car, I left the repair business and hired TCI’s first employee, a high school friend from Oregon, Lanny Marshall. I was going to be all in. The start was slow. I was showing the frame from the back of my old pickup way out in the back lot of the Great Western Exhibit Center when the kings of street rodding, Pete Chapouris and Jake Jacobs from Pete & Jake’s, stopped and said they were interested in buying my frames to put their product on. I have them both to thank for a very pivotal time in TCI’s growth.

GG: It appears the muscle car segment has surpassed the street rod area – what are your thoughts?

Moss: The hot rod market has remained stable. With younger enthusiast input, we launched into the muscle car and pro-touring markets years ago. This segment remains strong but was recently overtaken by the C10 and Blazer trucks and the four-wheel-drive Blazer. Fifty years ago, I never thought we’d be making truck frames.

GG: You’re a racer at heart – what’s the quickest and fastest times you’ve run?

Moss: I’ve been blessed to go racing again like the old days at the 605 Speedway in Irwindale. Back then, I drove a ’57 Ford in the NASCAR Hobby Stock division with a 250c.i. six-cylinder. I won the championship, and the next year got the championship at Saugus Raceway. Once you won in the six-cylinder division you had to compete with the big boys, so I built a ’66 Dodge Charger and raced at Riverside Raceway finishing 13th. I did better at Ontario, garnering a fifth-place finish.

I’m a much better oval or straight-line racer than road course or autocross. When I came to California in 1961, my uncle Dean took me to Lions Drag Strip to an AA/Gasser meet. I fell in love with the old cars with supercharged engines wildly going down the strip at 140mph. So, when Goodguys started the nostalgia drag race series, I wanted in!

Of course, it would have to be a Ford with a Ford motor. I won one race with the wedge motor, but the handwriting was on the wall; if I wanted to compete with Brad Anderson Hemis, I would need to go to a Ford Shotgun motor. With an excellent team, we won two Goodguys, AA/Gas Championships with the best E.T. of 6.59 at 211mph. Those were great times racing with some lifelong friends.

GG: What do you think the hot rod landscape will look like in another 10-20 years?

Moss: I don’t know, but I will say there are thousands of creative minds in the automotive world that love to tinker and create something totally different than anything done before.

GG: After 50 years in business, any words of wisdom to share with other companies getting started?

Moss: Get ready to put in the long hours, stay focused on the goal, surround yourself with people smarter than you, and when you mess up with a customer, admit it, apologize and make it right! This has been an unbelievable journey for 50 years and I’m praying for a few more. There have been so many great people and opportunities that have come my way, it couldn’t just be by chance – I truly have been blessed!