Shaping Steel – Tools & Tips for DIY Metalwork

Metalwork is an art, just like painting in oils, photography, or creating a sculpture. To become a professional, it takes years and dedication to the craft in one’s chosen field, but that doesn’t mean you can’t get involved, start learning, and try to tackle a few tasks yourself.

It seems that forming and shaping metal into a headlight bucket or engine cover is being done more than ever these days. We rounded up some of the most useful tools available for working metal, ranging from entry-level starter kits to higher-end professional machines. Whether you want to try your hand at louvers, roll a bead, or make a simple rust-repair patch panel, the tools are out there. And in this day and age, there are all sorts of online videos to view to start your learning process, or you can step up and take a training seminar or class.

We can’t all be a metal-crafting Picasso, Pollock or O’Keefe, but you can sure have fun trying your hand at some hot rodding metalwork.

Covell Creative Metalworking

Creating Curves

If you’re getting serious into shaping metal, one of the best tools you can have at your disposal is an English wheel. The English wheel, which came about well over a century ago, produces smooth curves, consistent bends and forms in metal. Covell Creative Metalworking offers its own Signature Series English Wheel that is built for years of durability and performance.

The heavy-duty frame allows you to shape 12-gauge steel with ease and will crush aluminum welds flat. The kick wheel is positioned low to make adjustments easy and it has a 30-inch throat depth to reach the center of a 5-foot panel. A large diameter tube on the screw-jack gives the machine extra rigidity while the unique A-frame leg design keeps the machine stable and secure. A durable powder-coat finish will keep the tool clean and in great shape for years to come.

Speedway Motors

Speedway Motors

Classic Holes

One of the best metalworking tools you can get started with (which is also highly addictive) is a set of Dimple Dies. Dimple Dies are the handy tools that give you the ability to form a perfect hole in sheet metal to give your work a custom touch. Speedway Motors offers a kit of seven different diameters which will have you punching holes in any extra sheet metal laying around your shop.

Interestingly, no drills are used to form these decorative holes, rather a heavy duty set of dies that work together to cut through the sheet metal. Using a bolt and nut will do the trick and the self-centering design will create consistent holes for custom touches on interior panels, radiator supports, and more. The Speedway kit includes ½-, ¾-, 1-, 1¼-, 1½-, 1¾-, and 2-inch dies that can be used on metal up to 16-guage thick. (Speedway also offers individual Dimple Dies on their website.)

Dagger Tools

Dagger Tools

Get Started

One of the most common questions Dagger Tools receives from students at the end of one of their Metal Shaping Classes is, “What tools do I need to get started?” The answer is in the company’s Metal Shaping Starter Kit.

This kit is supplied with the hand tools you’ll need to get you started in metal shaping and the restoration of existing auto body panels. Dagger’s kit is supplied with bossing mallets and body hammers to help lay out and raise metal, along with a joining/welding fixture, weld/seam prep tool, and other finishing tools. They also supply their handy Tips on Metal Raising Guideline.

Trick-Tools

Trick-Tools

Hammers and Blocks

To further enhance their depth of experience and tool offerings for metalworking, Pella, Iowa-based Trick-Tools teamed up with metal expert Ron Covell to create a Signature Line of Body Hammers and Dolly Blocks. These made-in-the-USA hand tools are specified by Ron Covell and are his favorite designs from more than 50 years of metal-shaping experience.

The Covell Hammers feature an octagon-formed hickory handle that limits rotation and produces a well-balanced, substantial feel with excellent grip. The dolly blocks feature five popular sizes that provide low and high crowns and numerous radii for complex shaping. Drop forged from high carbon steel, heat treated, then tempered and polished, these hammers and dollies are built to last for years to come.

Summit Racing Equipment

Summit Racing Equipment

Rolling Lips

Bulking up the tire/wheel combination of your muscle car can make a huge change in its attitude and handling, but there’s nothing worse than going for a test ride only to hear the tires rubbing on the inner fender lip. You might be able to hammer or trim the offending sheet metal, but that’s the caveman solution.

Summit Racing offers a Fender Rolling Tool (SUM-900790) that will help you produce a smooth finish by safely rolling the inner fender lip in to provide a little more clearance. The tool bolts directly to the wheel hub flange and has a reach of 14- to 22.75-inches from the hub to the edge of the fender so it fits most classics and muscle cars. Simply rotate the assembly and the ball-bearing-supported wheel will evenly roll the fender lip, creating the added clearance your new tires require.

Mittler Bros

Mittler Bros

Dead Blows

When it comes to working with metal, one of the most important tools is the hammer. We all love a good hammer, a staple of any toolbox or workbench pegboard, but when it comes to forming metal, hammers get more specialized. One of the most recommended hammers is known as a dead blow and Mittler Bros. Machine and Tool offers a number of different sizes and shapes of dead blow hammers.

A dead blow hammer is designed to produce minimal rebound, which reduces damage to the working area. Inside the head of a dead blow hammer is a sturdy canister filled with shot or a heavy sand material. As the hammer comes down the shot material is behind the head of the hammer and when it strikes, the inertia of the shot material continues down to help produce less rebound while imparting a hearty impact on the material. The strike is powerful, yet much more even and not as ‘sharp’ as a traditional hammer, which prevents damage to the working part.

Woodward-Fab

Woodward-Fab

Roll a Bead

When you’re fabricating new sheet metal panels, one of the most versatile and useful tools is a Bead Roller. Woodward-Fab recently made a number of improvements to their manual bead roller based on feedback from users. Updates include a thicker frame which allows the fabricator to more accuracy strengthen and stiffen sheet metal panels.

Other updates include an easy-to-adjust top roll handle, an OSHA-compliant gear cover, and an additional shearing die set along with 3/8- and ½-inch bead dies. The roller has an 18-inch throat depth to accept large panels and can easily handle up to 18-gauge mild steel and 1/16-inch aluminum.

Rodman Tool

Rodman Tool

Bits for Life

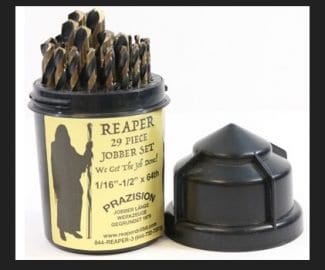

Drill bits are a tool that we all take for granted. We expect them to be sharp every time they’re chucked up and to drill through materials they probably shouldn’t. Rodman Tools decided to design a bit that would be ready all the time, even for stronger materials like stainless or spring seal.

Rodman’s Reaper Drill Bits are made of a patented, high-molybdenum M2 alloy designed to stand the test of time. A 135-degree split point produces an easy start without any drill walking. The precision-ground flutes and extra-wide web design prevent the bit from heating up and breaking like other bits. Each bit, from 3/16- up to ½-inch, is tooled with three ground flats on the shank to prevent slippage in drill motors with keyless chucks.

Baileigh

Baileigh

Shrink it – Stretch it

When it comes to crafting curved corners such as fender lips, window channels and more, the tool of choice is a Shrinker-Stretcher. This useful piece of shop equipment does exactly what its name implies – it stretches metal and/or shrinks it, which helps you create perfectly curved corners.

Baileigh Industrial offers a wide range of Shrinker-Stretcher tools, from garage-friendly models to the only hydraulic design on the market. Their most popular model is the MSS-16F which handles up to 16-gauge mild steel, has a generous 6-inch throat, and offers foot pedal control leaving your hands free to work the panel. Baileigh includes two sets of quick-change rounded jaws to keep marring to a minimum (optional jaws for aluminum are also available). The tool is perched on a cast iron stand finished with rolling casters to easily move the machine when not in use.

Snap-on

Snap-on

Grip It

Every garage and shop needs a heavy-duty vise to grip and secure metal projects as you work. You’ll be amazed at how often you use a vise and wonder how you got along without one once you bolt one to your workbench.

When you choose a vise, go big and go heavy-duty. Snap-on’s Blue-Point series offers a number of vises in shapes and sizes. This 6-inch model has a max opening of 9-inches with an alloy steel slide bar placed in a 60,000-psi high ductile iron foundation. The steel jaw inserts can be replaced and the unit can be rotated and locked in place to ease use.

Lincoln Electric

Handy Protection

Working with sheet metal can be tough on your hands. Drilling, cutting and forming all produce sharp edges, but when you add welding and torch work to the equation, things get really precarious for your digits.

Lincoln Electric understands the importance of protecting your hands and arms, especially when you’re welding. Their new DynaMIG HD Welding Gloves are made of white top grain and black split cowhide to offer protection in low to high welding applications. The gloves are designed to allow easy movement for working and are available in sizes from medium to 2XL.

Goodson

Goodson

Marking Metal

Working with metal involves oils and grime that easily remove any measurements or cutting marks you need as you’re working. Goodson Tools offers a Metal Marker with a quick-dry formula that withstands grease and surface contact. In short, it won’t just be wiped away! The markers are always at the ready, but we bet you’ll still shake it even when you don’t have to.

TECH TIP 1 – Ron Covell – Why Metal Warps when Welded and How to Fix It

TECH TIP 1 – Ron Covell – Why Metal Warps when Welded and How to Fix It

Ron Covell has been teaching the art of metal working to beginners, intermediate, and advanced students for more than 25 years. When asked about the most common question that comes up, without hesitation he said, “why does metal warp when you weld it, and how can you fix it once it has warped?” We’ll let Ron take it from there.

“The short story is that metal shrinks when it’s welded, and the shrinking pulls on the adjacent metal, causing it to buckle and warp. The thinner the metal and the more heat you put into it, the more warping you’ll get. Fortunately, there’s a straightforward way to correct this distortion. Hammering on-dolly will stretch the metal, and if you stretch it exactly as much as the welding shrank it, the metal will return to the shape it had before it was welded. While this is easy to explain, it takes a fair amount of practice to learn how much stretching is required.

It is important to note that not all welds are the same. TIG and oxy-acetylene welds are fairly soft, so you can hammer them quite a bit. I recommend sanding the weld bead flush before hammering, which reduces the volume of metal you need to hammer flat, but both of these types of weld give you a lot of leeway with your hammering and can survive even when you need to go ‘back and forth’ if you over-stretch an area a bit.

MIG welding, the most common welding process, leaves a weld bead that is quite large and considerably harder than the others. You can do a certain amount of hammering on a MIG weld, but you will reach its limits sooner.

With a little practice, most people get the hang of this process after a few trials and the more you do this kind of work, the easier it gets!”

TECH TIP 2 – Metal Strip, Clean and Prep

Anyone who works on old cars will come across the need to remove old paint, rust and even body filler at some point. While there are many ways to achieve a clean work area, including chemical strippers or blasting, sometimes it’s best to stick with the basics. One of Ron Covell’s favorite tools for cleaning metal is a Scotch-Brite ‘Clean and Strip’ disk with an air-operated die grinder.

Ron explained that this method much better than sanding, since it doesn’t thin the metal like the sanding action can. He also mentioned that the Clean and Strip disks work great on chassis projects as well.

TECH TIP 3 – Raising Panels by Hand Shaping on the Bag

Dagger Tools offers a number of metalworking courses through the year that cover forming, buck designs, wheeling and raising, and more. The classes are given at their Wixon, Michigan, facility just west of Detroit. They shared several tips for raising panels through hand shaping on the bag.

• Make sure you have enough surface form to complete the form (use a cardboard reference template, foam form, or other template).

• Transfer any information noted during template process to rough panel cutout: possible shrink points, highest panel areas, any flat zones etc.

• Identify highest area(s) of panel to be shaped.

• Maintain a reference center line in two directions to properly align the shape with the template panel

• Set edges early into raising process to help minimize adjoining surfaces from changing or having metal pulled from them while raising metal main panel areas.

• As you stretch the metal on the bag the edges will turn up; you need to relax or push them down to create a uniform shape and accurate representation of the amount of stretching to that point.

• Condition yourself to adjust all panel surfaces together as you work to raise the highest zones.

TECH TIP 4 – Get Schooled

TECH TIP 4 – Get Schooled

From weekend workshops, to community college courses, to specialized technical schools, there are plenty of avenues for learning to do metalwork and fabrication. You can event find great how-to DVDs and online video tutorials to learn on your own. No matter which method you choose, though, nothing beats the knowledge gained by diving in and giving something a try with your own two hands.

Central Carolina Community College is one of many schools offering an Automotive Restoration Technology Diploma which covers metalwork and panel repair. Kassidy, a student at the school, was showing what she’s learned recently at the Goodguys North Carolina Nationals in Raleigh.

Speedway Motors

Speedway Motors Dagger Tools

Dagger Tools Trick-Tools

Trick-Tools Summit Racing Equipment

Summit Racing Equipment Mittler Bros

Mittler Bros

Woodward-Fab

Woodward-Fab Rodman Tool

Rodman Tool

Baileigh

Baileigh Snap-on

Snap-on Goodson

Goodson TECH TIP 1 – Ron Covell – Why Metal Warps when Welded and How to Fix It

TECH TIP 1 – Ron Covell – Why Metal Warps when Welded and How to Fix It TECH TIP 4 – Get Schooled

TECH TIP 4 – Get Schooled