Tech Tip: The Most Important Tool

I suppose all hot rodders are tool freaks to some extent. We collect them, store them and learn how to use them. What baffles me, and causes a lot of trouble for some rodders, is not using the most important tool….. A tape measure! Sure, we know how to measure to build part of our car, but why don’t we use one when we are planning our projects?

I suppose all hot rodders are tool freaks to some extent. We collect them, store them and learn how to use them. What baffles me, and causes a lot of trouble for some rodders, is not using the most important tool….. A tape measure! Sure, we know how to measure to build part of our car, but why don’t we use one when we are planning our projects?

In particular, all too often, project cars and chassis parts are combined without sufficient planning and measuring. It is very unlikely that an old car and a proposed donor car you just happen to have lying around will fit together well. When GM subframe transplants were popular in the ‘70s and ‘80s, many problems occurred. Wheels were not properly centered in fenders, ride heights were not planned, and interferences between steering boxes and sheet metal were common occurrences. The new and old frame horn positions were often so mismatched that bumpers were either mounted on some pretty atrocious angle iron creations or simply left off altogether. Many cars required dropped spindles, special springs, or control arms with narrowed widths and repositioned ball joints to solve these fit problems. In fact, the tubular arms and coilover conversions now used on Pro-Touring cars today were founded on fixing these kinds of problems and later came to be used on the actual donor cars themselves.

Unfortunately, some rodders thought that a ’79 Camaro subframe that worked well under a ’56 Chevy pickup would also work nicely under a ’37 Ford. The use of a tape measure would have made it clear that the ’37 Ford fenders are about 5” narrower than the truck. That and the fact that the engine needs to sit about 5” further back led to many problems with track width and spring selection. You would think we had learned, but it seems every generation has to relearn the lessons of the one before.

Unfortunately, some rodders thought that a ’79 Camaro subframe that worked well under a ’56 Chevy pickup would also work nicely under a ’37 Ford. The use of a tape measure would have made it clear that the ’37 Ford fenders are about 5” narrower than the truck. That and the fact that the engine needs to sit about 5” further back led to many problems with track width and spring selection. You would think we had learned, but it seems every generation has to relearn the lessons of the one before.

Now we see S-10 subframes under ’47-’54 Chevy pickups where the new IFS is so narrow that either 3” wheel spacers or wider control arms are needed. The Ford pickup guys find the Crown Victoria IFS easy to install, although it is 7” wider than the stock front suspension….always a danger sign on a lowered vehicle. We regularly have rodders visit us at a show asking how to narrow ’73 and later Chevy pickup suspensions that they have swapped into an early truck. They will describe how it was pretty easy to do, fairly cost effective and fits perfectly. At that point I ask “then how can I help you”? We apparently define “fit perfectly” in a different way, since the usual response is “it’s about 3” too wide per side”. Since there is no way to narrow that IFS that much, the only real fixes are to widen the fenders or start over again. You can fix some clearance problems with special offset wheels, but there are limits on what style wheel can be changed, how much change can be had, and how these extreme offsets affect handling and bearing stress.

Then there are the complete chassis swaps for cars. Wheel clearance and axle position problems often occur. If the track width and wheelbase do indeed work out, there is still the issue of the frame rail contours matching the original floor, as well as the body mount positions themselves. Of course, if the floor needs to be completely replaced. This may not be a real big problem, but I don’t think many guys would feel good about cutting out a good factory floor to make the body fit a donor chassis.

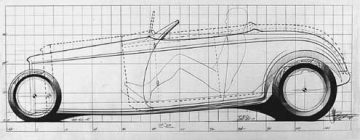

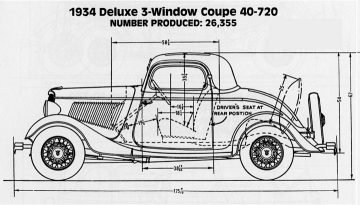

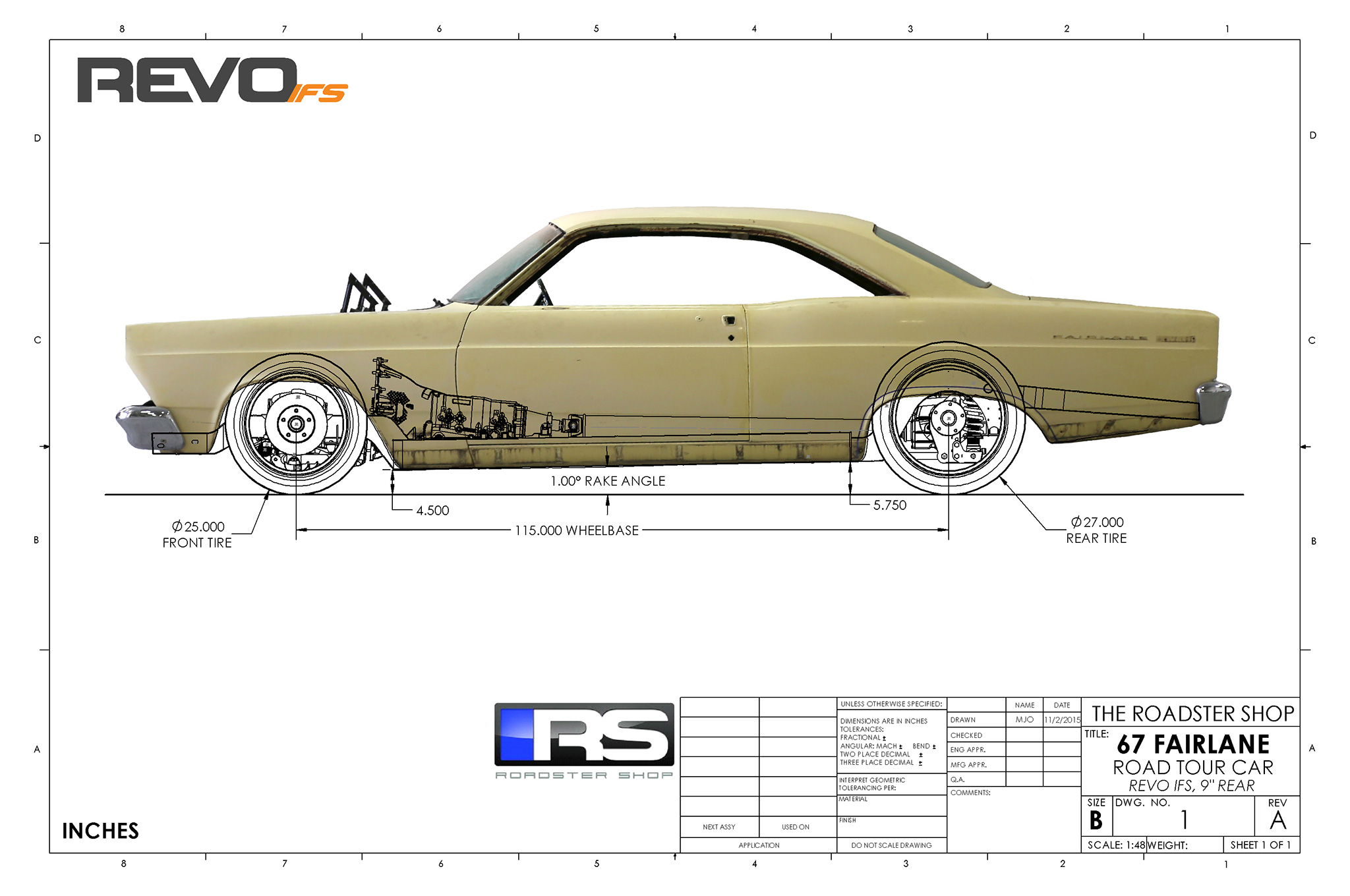

Believe it or not, even though I make my living building IFS kits, I understand trying to save money on a hot rod project by using salvaged parts and chassis. A lot of these kits came about as a way to solve problems where there wasn’t a good fit from a donor suspension or frame. There have been too many cases where a good car has been ruined or resulted in a build made too complicated by a poor choice of components to be installed. If you are going to use parts from a donor car, shouldn’t you first make sure they are going to fit? Use that tape measure and check the wheelbase and track width! Don’t just plan on “fixing the fit with special offset wheels” later on. Do some homework on a complete vehicle like your proposed donor car to see what the factory ride height is, related to some point on that chassis. Then, use the tape measure to see how you have to install the new/old parts to get the ride height you want on the finished hot rod. Don’t expect to alter ride height more than a couple inches either way without creating suspension travel and geometry/alignment problems. If you are doing a complete frame swap, make a scaled side view drawing of the donor frame versus the original frame so you can foresee any problems which will be difficult to solve.

Believe it or not, even though I make my living building IFS kits, I understand trying to save money on a hot rod project by using salvaged parts and chassis. A lot of these kits came about as a way to solve problems where there wasn’t a good fit from a donor suspension or frame. There have been too many cases where a good car has been ruined or resulted in a build made too complicated by a poor choice of components to be installed. If you are going to use parts from a donor car, shouldn’t you first make sure they are going to fit? Use that tape measure and check the wheelbase and track width! Don’t just plan on “fixing the fit with special offset wheels” later on. Do some homework on a complete vehicle like your proposed donor car to see what the factory ride height is, related to some point on that chassis. Then, use the tape measure to see how you have to install the new/old parts to get the ride height you want on the finished hot rod. Don’t expect to alter ride height more than a couple inches either way without creating suspension travel and geometry/alignment problems. If you are doing a complete frame swap, make a scaled side view drawing of the donor frame versus the original frame so you can foresee any problems which will be difficult to solve.

The bottom line is that to get what you want in a hot rod build (or almost anything else you might attempt in life) there has to be a well thought out plan. To have such a plan you have to start at the end and work your way back. Find out where the wheel centers need to be to get the ride height and wheelbase where they look right in your eye. Then determine whatever is needed to get there and commit to doing that, no matter how difficult it may be. Then you may decide another path would be better before you spend a lot of time, effort and cash on a swap that is doomed to failure from the beginning. This is still important if you are using a commercially made suspension kit. The manufacturer should be able to get you the track width and ride height information you need.

I greatly fear that this column will sound too critical or negative regarding building hot rods with salvaged parts. Please forgive me if it seems that way but I have seen too many cases where trying to save money ended up creating too many problems. Sometimes trying to save money ends up costing more and satisfying less. When one fix is piled on another, the result is often less than desirable.

So how can you know where you want to go, and what has to be done, without using that most valuable tool, the tape measure? Well, maybe an active brain would be the very most important tool, but the brain needs information to process and the lowly tape measure is one of the best sources of that information. Before you spend hours and money on building your hot rod, buy a good tape measure and use it. And be willing to reconsider when the tale of the tape forecasts trouble coming your way.