Shop Profile: Speedtech Performance

Speedtech Performance is well known for its line of high-performance chassis systems. In addition, though, tucked away in its 20,000 sq. ft. facility in St. George, Utah, is a custom shop that not only installs the company’s products, but creates and builds vehicles from the ground up.

From autocross-ready muscle cars to one-of-a-kind builds, the custom shop has a reputation for producing rides that not only look good but perform like new muscle cars. Speedtech Performance opened its doors in 2005 in Vancouver, British Columbia, to fill a void in the Canadian market for performance suspension products. Starting with a handful of suspension pieces for first-generation Camaros, the company grew rapidly to the point where product demand outpaced manufacturing capabilities.

- Photo by Scott Schwartz

By 2007, Speedtech’s founder decided he needed to hand off the company to a more experienced team. That’s when partners Blake Foster, president, and Roger Maniscalco, vice president, bought the company. With their combination of custom shop and financial management skills, the pair began to expand Speedtech’s offerings.

Adding parts for ’64-’72 Chevelles, second-generation Camaros, ’68-’74 Novas and ’94-’96 SS Impalas, Speedtech Performance began a period of sustained growth. In 2012, the company moved its operation to St. George, Utah, and a third partner, vice president of sales Jay Weir, joined the team.

You Want It, They’ll Build It

While much of the shop’s work involves installing Speedtech chassis and components to existing vehicles, ground-up builds involve a variety of makes and models.

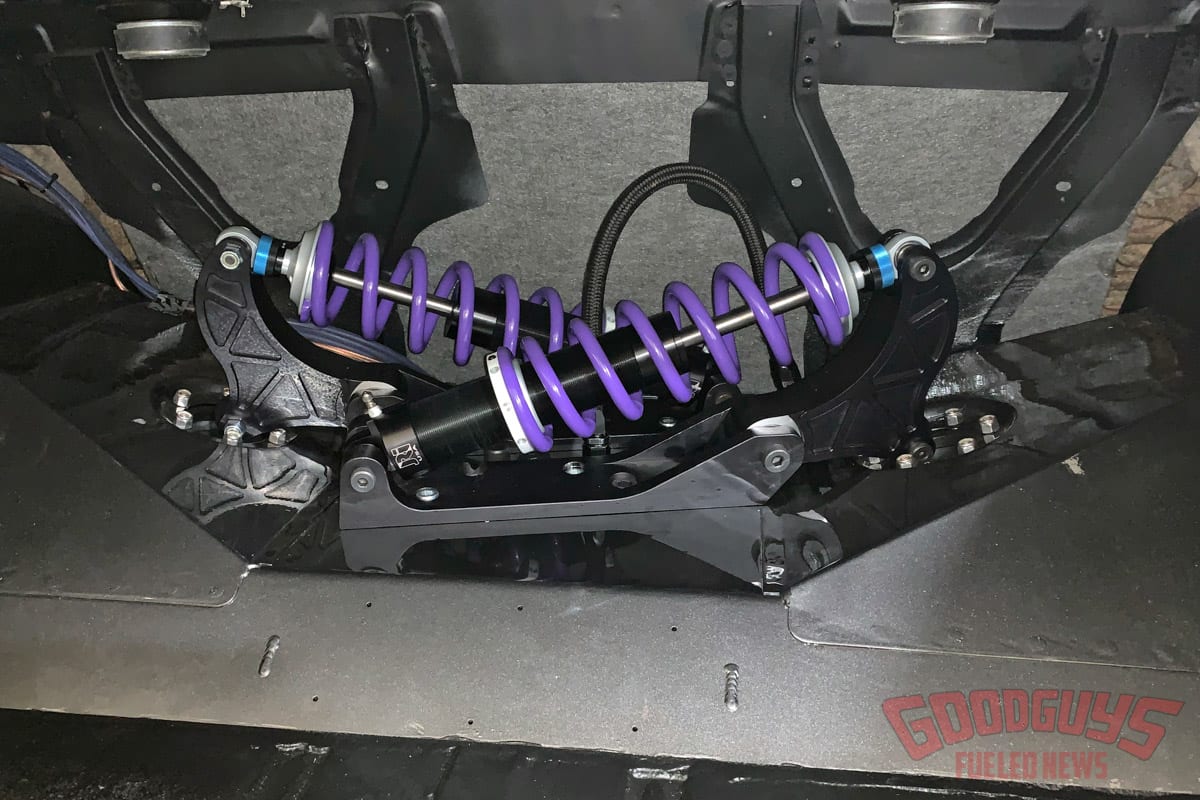

This second-gen Camaro belongs to a Speedtech employee and showcases both the company’s products – like a Track Time suspension system and torque arm rear suspension – as well as the custom shop’s build capabilities.

“We always have multiple cars – Chevelles, Chevy IIs, Camaros,” says Cameron Foremaster, Speedtech’s marketing director. “We’ll do anything a person wants to pay for, whether it’s a Jeep or a muscle car.”

- Unusual projects are no problem. This ’65 International Scout is on its way to becoming a fun, one-of-a-kind cruiser with a Speedtech Extreme chassis and LS3 engine.

Consider two current projects: A 1965 International Scout and a 1929 three-row Cadillac. Not your average builds, for sure. The Scout is getting the full treatment: Speedtech Extreme chassis, 525hp LS3 engine, custom body, interior, sound system. “We used a windshield from a Chevy II, so it has a bit of a rake to it, not just leaned back,” Cameron says.

- The Speedtech team is equipped to handle all aspects of fabrication, plus bodywork and paint. An in-house paint booth helps the team retain control through the refinishing process. About the only service that’s outsourced is upholstery work.

The ’29 Caddy belongs to a company that does Grand Canyon tours and it wants the car to be safe, but look original, so it’s getting a custom-built chassis and LS power.

Small, Experienced Staff

While only three full-time employees staff the build shop, several other Speedtech Performance employees help as needed, bringing added skills to the team that includes builders who previously worked for Kindig-It Designs and on the Overhaulin’ television show.

- Updated engines and transmission often require custom clearances. Modifications like this custom tunnel to accommodate a bigger transmission are routine for the Speedtech build crew.

Cameron says the build shop offers installation, fabrication, bodywork, and paint. Interior work is outsourced to professional auto interior specialists. The build team emphasizes modifications that make vehicles perform better. “We spend a lot of time making sure the suspension is dialed in the way it needs to be,” Cameron says. “We don’t want them to just look pretty, we want them to perform like new a new car.”

Design, Then Build

Customers work with the shop team to design project vehicles on the computer before any actual work begins. In the case of complex full builds, Cameron says, they will often use the services of designer Ben Hermance to create exterior and interior renderings. The design process goal is to build the car once. “We build the car on the computer so we all agree,” Cameron says. Then, the work begins and the customer isn’t surprised when the job is complete.

- Though known largely for muscle cars, Speedtech can tackle just about any style of build. This ’55 Chevy is getting a supercharged LS and custom engine bay metalwork, in addition to a performance chassis.

In addition, out-of-state customers who can’t visit Utah regularly to see the work in progress can take advantage of photo updates over the internet. “We try to do that weekly,” Cameron says. “Even if it’s in a slow phase where we’re waiting for parts, we’ll still tell the customer that we’re waiting for parts,” so he’s always up to date.

Ford Future

Most of the company’s product line is geared toward GM muscle cars and a few Ford truck applications, so the builds coming from the shop reflect that. But a current shop project will produce the first Speedtech Extreme chassis for mid-’60s Mustangs. A ’65 Mustang fastback build will be the test platform for the new Mustang chassis series.

Bentley Hugie’s high-impact ’54 Ford F100 is a great example of the quality and creativity to come out of Speedtech. From the performance Speedtech chassis, to the supercharged GM LT4 engine, to the machined aluminum grille and brilliant blue finish, this truck is stunner that also delivers stellar performance.

Before being added to the product line, the Mustang chassis will be dialed in at the company’s autocross track, located on four-acres of asphalt behind the main building. The course also allows chassis installations done in the build shop to be tuned before customer delivery. If all goes well, Speedtech Performance plans to hold an open house later this year that will include a poker run. Participants will have to drive the autocross course (not at speed) to earn their last card.

Picking a Builder

Before designing a project vehicle, Cameron says they try to make sure the customer really knows what he or she wants. “The customer needs to realize what they want to do with the car,” Cameron says. “What kind of final product do they want? Do you want a show car that you can trailer or drive 10 miles to a local show, or do you want a daily driver or something that you can put on an autocross course?

“A lot of people will waste a lot of money building a car and then realize that wasn’t what they wanted. Research not only the looks, but the feel. There’s a big difference between 500 horsepower and 800 horsepower. Don’t be afraid to ask questions.”

That’s sound advice whether you just upgrading an engine and transmission or starting on your dream car.

Speedtech Performance

4160 S. River Road

St. George, UT 84790

435.628.4300

www.speedtechperformance.com

Photos Courtesy of Speedtech Performance