MetalWorks Classic Auto Restoration and Speed Shop

Take a walk around MetalWorks Classic Auto Restoration in person, or check out their website and you’ll clearly see they build amazing cars. MetalWorks’ restorations and custom builds are a point of pride with the Eugene, Oregon shop, which is a common thread among top builders. But what is not common is the fact that building cars in not the shop’s main focus. To get a better understanding of this I sat down with shop founder and owner Jon Mannila (At far left below) to dwell deeper into the mind set and mission statement of this hidden jewel in the Pacific Northwest.

Jon explained to me, “As a high volume build shop we have taken cars from ground zero to driving out the door. We have done this for many years. During all those builds, the amount of parts and combinations of parts used has given us a real education. Simply put, not all parts work in harmony with each other. Problems can occur such as not parts not mating together, poor performance, reliability issues, and just simply poor quality.”

Jon continued “We have taken in many projects where the customer has supplied many of their own parts, and it’s very rare for us to be excited about their selection of components. With kind words we simply point out the good and bad, make a list, and fill it in with parts we know will do the job. Being a build shop that puts these cars out on the road, our number one goal is reliability. When something fails, the car comes back to the shop, and we are fixing it under warranty. Warranty work doesn’t keep the lights on, so you can imagine our motivation to make them reliable.”

By seeing this purchasing pattern over and over again by customers who brought their cars to the shop, Jon came to recognize a need for guidance, and developed a passion for designing the “right” parts combination for people.

Imagine being able to reach out and pick the brain of one of the top build shops around…who wouldn’t want to do that? To be able to find out exactly what they recommend from real world experience, and then be able to purchase those parts directly from them at outstanding prices.

That is exactly what MetalWorks prides themselves on and offers to their customers. “We’ve bought in deep with all of the vendors we trust and believe in, and we pass that savings and knowledge onto our customer” Jon stated, “it’s a whole different experience than contacting a big box store where you are talking directly to someone who installs the parts you are looking to purchase on a daily basis. It’s a fun moment when the average builder saves up enough money to make a parts order, but all the fun ends when the parts order arrives, and the components do not match or function together…we never want that to happen for our customers.”

While I was talking with Jon he received a call from a new contact from the East Coast, I asked Jon to take the call while I observed the process. The gentleman was interested in an Art Morrison chassis, but beyond that he wasn’t totally sure what he wanted for components, but he did describe to Jon the level of performance he was aiming at with this car. Jon systematically walked the caller through the process of choosing his driveline components, then matching those components to everything from brakes to an EFI gas tank. Jon did not try and oversell the chassis package he was designing for the customer. There is no need for 14”rotors and 6-piston brake calipers if your desire is a weekend cruiser, nor would you want the improper rear end gearing that doesn’t match your desired 6-speed manual transmission. The conversation was very genuine and detailed, and by the time Jon hung up the phone he had designed and sold the gentleman a fully assembled and painted rolling chassis that the buyer could set his TriFive body onto. How many expert builders offer that kind of one on one service?

After the phone call we hit the shop floor. The first stop was the fabrication shop which housed several car bodies at what the shop refers to as ground zero, which translates to projects that are fresh from their acid dipping facility.

MetalWorks has been dipping their car bodies for over 20 years. Once dipped to remove all rust and paint, projects undergo all metal repair as well as custom fabrication. All components from sheet metal, AC units, gauges, etc are mocked up to ensure proper fit so that no “post paint” modifications will be necessary.

Next we headed to the body and paint shop which was filled to capacity with projects mid-body work. Some were perfect examples of factory specs, while others displayed credit card gaps, all dependent upon the wishes of their customers. After the bodies are massaged and painted to perfection they head to the assembly bay.

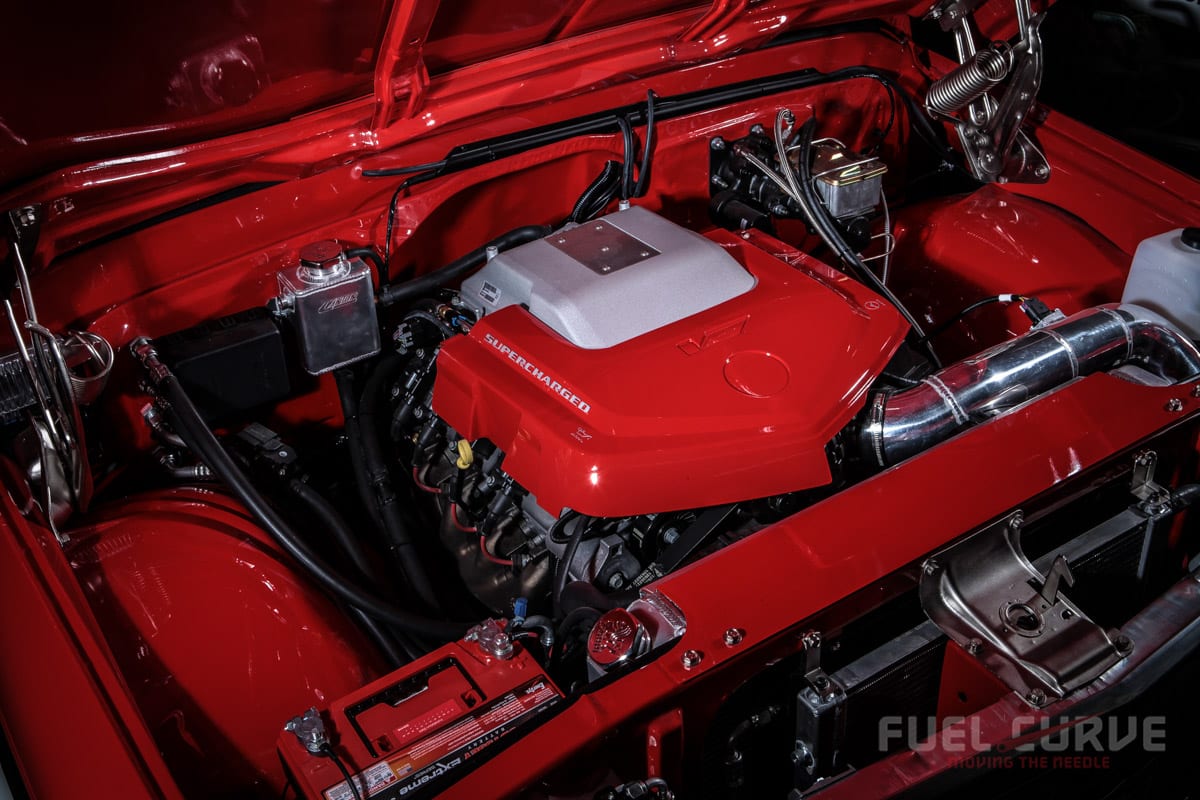

This area of the shop is exciting as the builds start to look like cars again. The projects on hand displayed many LS conversions in Pro-Touring level builds as that is a shop specialty, and the majority of the cars sat on Art Morrsion chassis as MetalWorks is the largest dealer for AME chassis in the world.

Lastly we checked out the onsite Speed Shop…aka, “The Candy Store.” Here you can purchase anything from radical Whipple Supercharged LS engines by Wegner Motorsports, to a variety of stock GM Performance LS platforms, to FiTech fuel injection systems, Dakota Digital gauges, RICKS EFI gas tanks…it’s a hard place on an enthusiast’s wallet!

If this all sounds enticing, you might have found your next builder. If you’re still on the fence, do yourself a favor and follow their builds (in an amazing step by step process) which are available on their website for your viewing pleasure. MetalWorks Classic is the perfect combination of a mom and pop, friendly speed shop that sells at prices matching the big box store, paired with a top level car-building facility. It doesn’t get much cooler than that.