Building the Goodguys Giveaway ’85 Squarebody – Part 3

So far, the coverage of the Goodguys Grand Prize Giveaway Squarebody ’85 Chevy pickup has focused on this trick truck’s foundation and mechanicals. We’ve shown you the Roadster Shop Slammed SPEC frame, the potent LT1 crate engine from Pace Performance, the Gearstar 4L65E transmission, and the wide range of support components and other pieces coming together at Goolsby Customs in Alabama.

This month we’re going to focus on one of the things the Goolsby Customs team does best: custom metalwork. While the Eric Brockmeyer rendering of the truck doesn’t incorporate major mods, the truck will have a number of subtle updates to make it a distinctive custom cruiser. Couple that with some needed repair and alterations to accommodate other custom parts – like slicing the bed floor to fit the Slammed SPEC chassis – and there were plenty of metal modifications to be made.

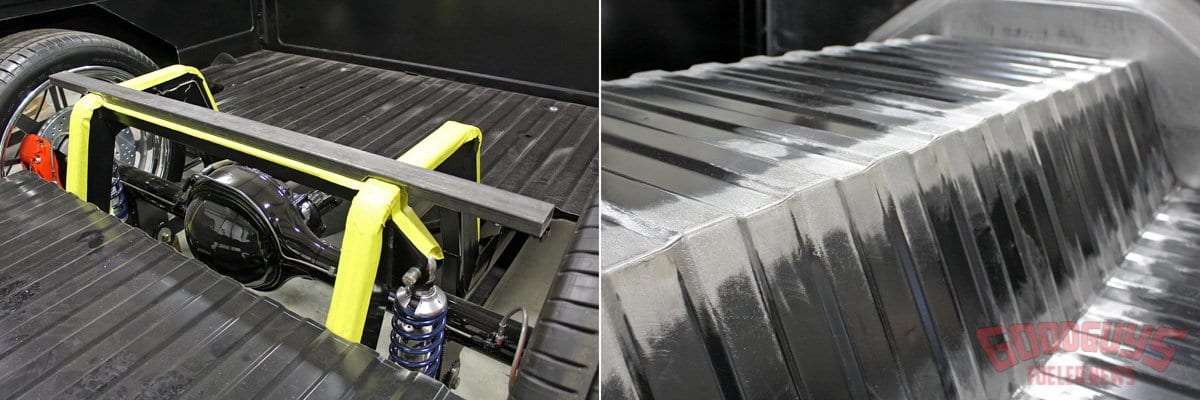

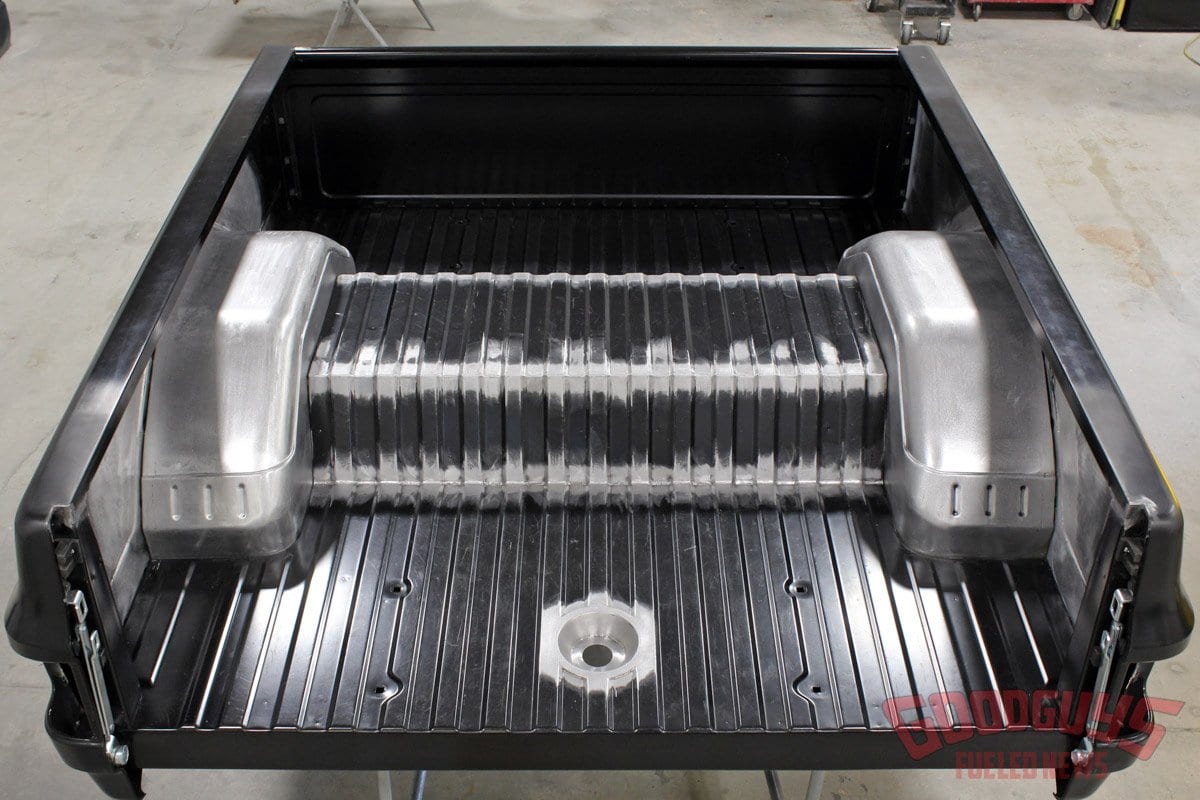

- Assembling the new bed sides, floor, and front panel from LMC was pretty straightforward. Then the new floor was cut apart into three pieces so a step could be built over the kickup in the frame.

Fortunately, Goodguys has LMC Truck on board as one of the truck’s sponsors. The company’s expansive range of truck parts includes a full selection of replacement sheet metal for 1973-87 Chevy and GMC trucks – and full advantage was taken from those offerings. A literal truckload of truck sheet metal was delivered to Goolsby Customs – everything from a replacement hood to the complete bed assembly (side panels, floor, etc.) so the Goolsby team could construct a new short bed to replace the original long bed assembly.

Most enthusiasts realize that even seemingly simple procedures like replacing a hood require a certain level of skill, especially when the goal is to have precise, show-quality gaps and fitment. In other words, the Goolsby team still invested a lot of time and care when assembling and fitting both the stock and replacement parts onto the body. The custom fun came in the form of small touches like a filled fuel filler door, custom firewall panel, filled top seam, custom transmission tunnel, narrowed bumpers, and custom inner fenders – construction of which was shown last week HERE.

The custom metalwork started on the cab, with subtle modifications like this custom firewall filler panel that matches the custom inner fenders.

Welding the seam on the top of the cab helped to start smoothing things off.

Inside the cab, the Goolsby Customs team built a custom transmission and driveshaft tunnel to accommodate the truck’s low stance and larger 4L80E Gearstar transmission.

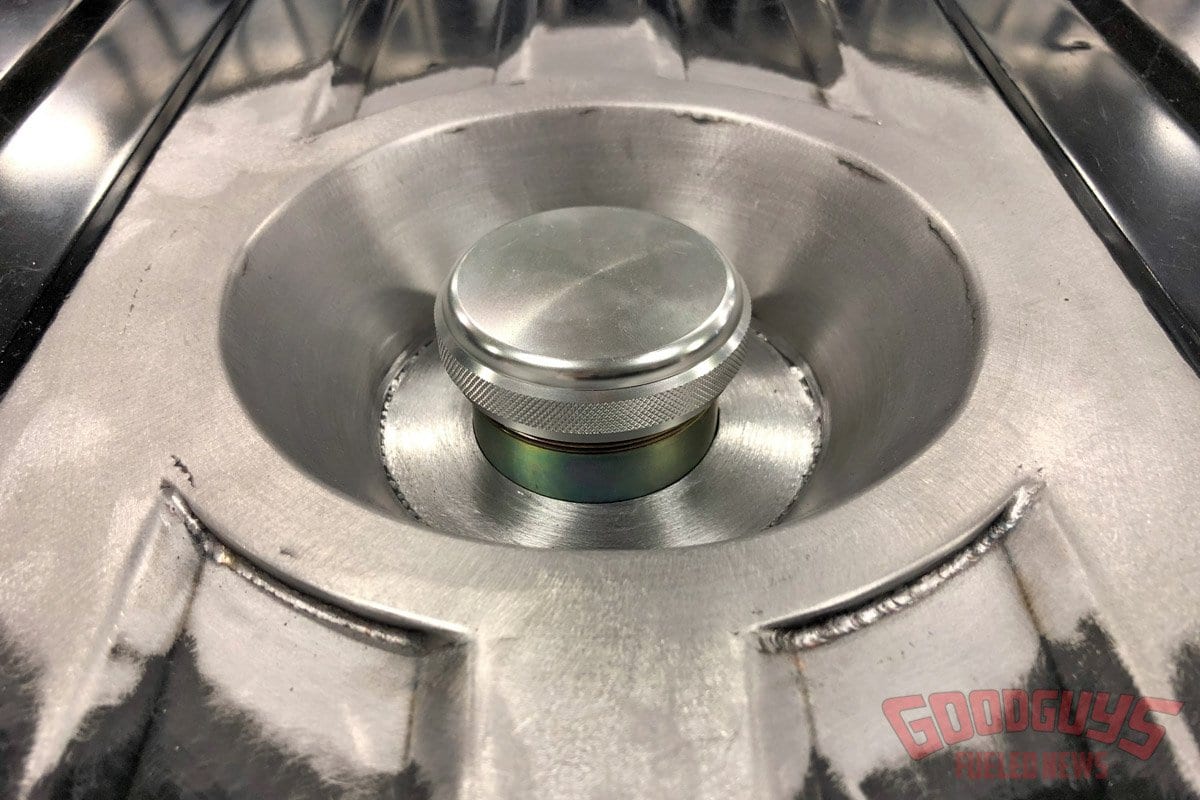

- One other bed floor modification was installing this recessed filler assembly for the Tanks, Inc. fuel tank.

- Tucking the bumpers tighter to the body meant slicing them in half, removing little material from the middle, and welding it all back together. The ends were also modified to better fit the body contour.

Some of the more substantial body modifications were to the bed floor and wheel tubs. With the large step on the rear of the chassis tucking the rear axle up high, the bed floor needed to be either raised completely or stepped to match. The Goolsby team opted for a step. This involved cutting a large section out of the middle of the floor, splitting that section into thirds (two inclines and a flat top) and welding it all back together in precise alignment. The wheel tubs then had to be raised, extended, and modified to fit. It was a lot of work, but the Goolsby crew made it look easy.

A support brace was built from rectangular tubing to sit atop the frame kickup and support the floor. The middle floor section was then cut into three pieces and skillfully aligned and welded back together to create the new shape.

The low stance also required modifying the inner wheel tubs. The team started with wider-than-factory tubs from LMC Truck and actually narrowed them several inches. They were extended vertically since they will now sit higher in the bed. The mounting flange on the inner bed side panel had to be cut out and raised to accommodate the new position of the tubs.

With the modified pieces assembled, everything looks like it belongs. As usual, the talented Goolsby Customs team makes all this work look easy and clean.

Additional body mods included filling the original door handle holes to prepare for the billet aluminum Pro Edge door handles from BBT Fabrications, which included upgrading to new late-model electric door latches, too. While the different body modifications were being completed, the team also got busy with panel alignment and the hours of fine tuning required to get everything fitting as it should. As different portions of the metalwork and prep processes were completed, the various body panels and sections could be rolled into the paint booth so high-build primer could be applied, setting the stage for the hours of block sanding required for a flat, smooth finish. We’ll dig into that more next month.

The stock door handle holes were also welded shut in preparation of new custom handles from BBT Fabrications. The new handles use modern GM electric door latch assemblies, so the jambs and strikers had to be modified to accommodate those.

As portions of the metalwork and panel alignment processes were completed, the different body sections could be rolled into the paint booth for the next round of primer. Black BASF epoxy primer was used to cover the bare metal after the metalwork was done, and then a gray high-build primer was applied. This primer allows for the hours of block sanding required for a flat, smooth finish. Check out those tight, precise door gaps!

It can make you cringe to cut and drill into freshly straightened and primed metal, but that’s just what Ben did to install the new billet aluminum Pro Edge door handles from BBT Fabrications. These handles have a modern, high-quality feel and an appearance that’s just a little more custom and distinctive than stock.

It’s a little out of sequence, but we couldn’t resist showing the assembled body in primer, sitting nice and low on the Roadster Shop chassis and Billet Specialties wheels. It’s getting close to having some color on it!

Photos by Goolsby Customs