Dominator Street Rods – Function and Form

Leonard Lopez of Dominator Street Rods learned a valuable lesson as a young man driving and working on race cars: Everything on the car must be functional.

Perhaps that simple lesson is the reason why his shop in Tracy, California, has turned out so many stunning vehicles over the past 30-plus years, from top-notch hot rods and customs to the slick Goodguys tractor-trailer rig that crisscrosses the country.

Dominator Street Rods also prides itself in providing a wide array of services. Consider the list outlined on the shop’s website: full-custom builds, body fabrication, electrical, chassis, headers and exhaust, restorations and insurance work on hot rods and classics that need the special care to recover from highway injury. A walk around the shop validates the variety of work performed for its customers: a ’60s Mustang, a ’30s hot rod pickup, Tri-five Chevys, a ’50s Cadillac, and more. That versatility – combined with an insistence on quality and style – helps to keep the shop busy and in demand.

MANAGING THE WORKLOAD

After his early race shop experience, Leonard worked for a couple of hot rod shops before striking out on his own to start Dominator Street Rods. The shop now has a team of experienced craftsmen and 20 or so vehicles in the facility at any one time. That number of projects, as well as a waiting list of customers, requires careful management. Leonard said he tries to diversify the types of projects in the shop at any given time. “If it’s all long-term stuff, it locks the place up,” he said. “We try to split it up between turn-key projects, repair projects and maintenance work. We actually have two or three waiting lists.”

In addition to the waiting lists, as part of the shop’s policy to bill customers weekly, there is a wall monitor and keyboard in the shop. Workers log in and out throughout the day, charting a project’s time and hours worked on it. Tracking hours as they are worked on helps keep the shop – and the customer – up to date on the time and money spent on each project.

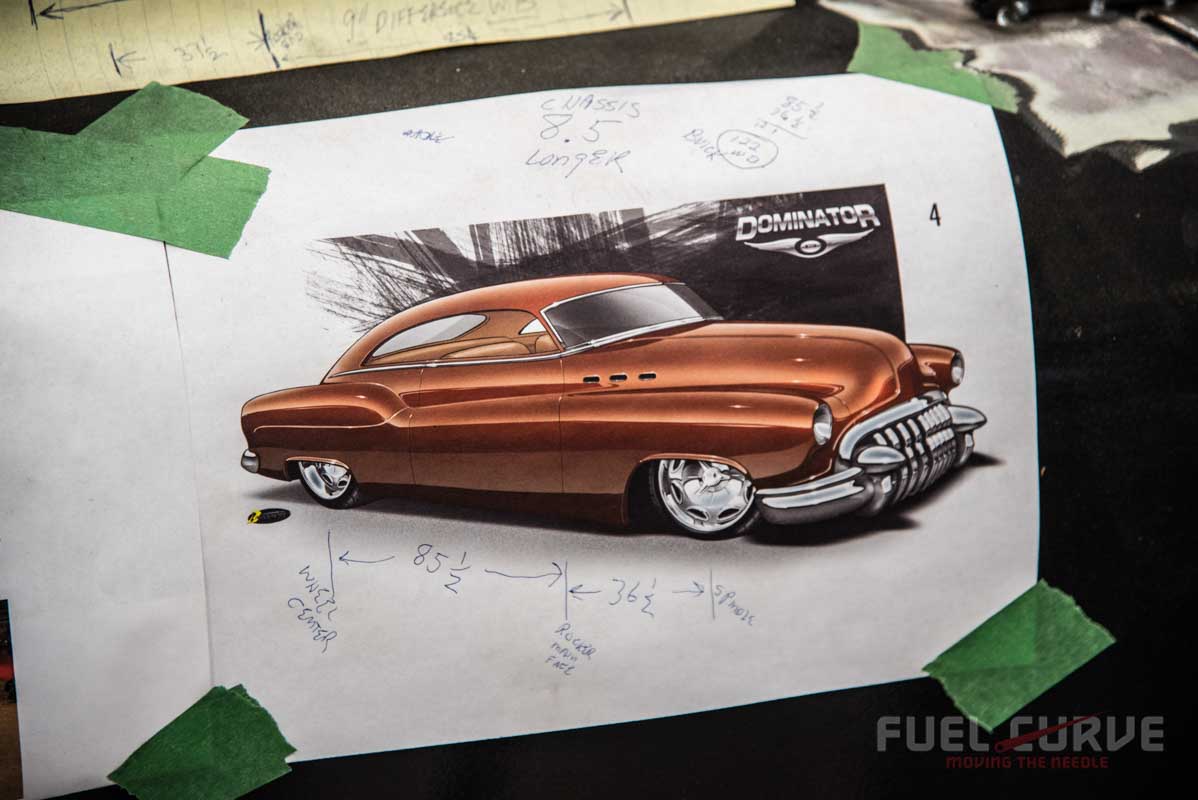

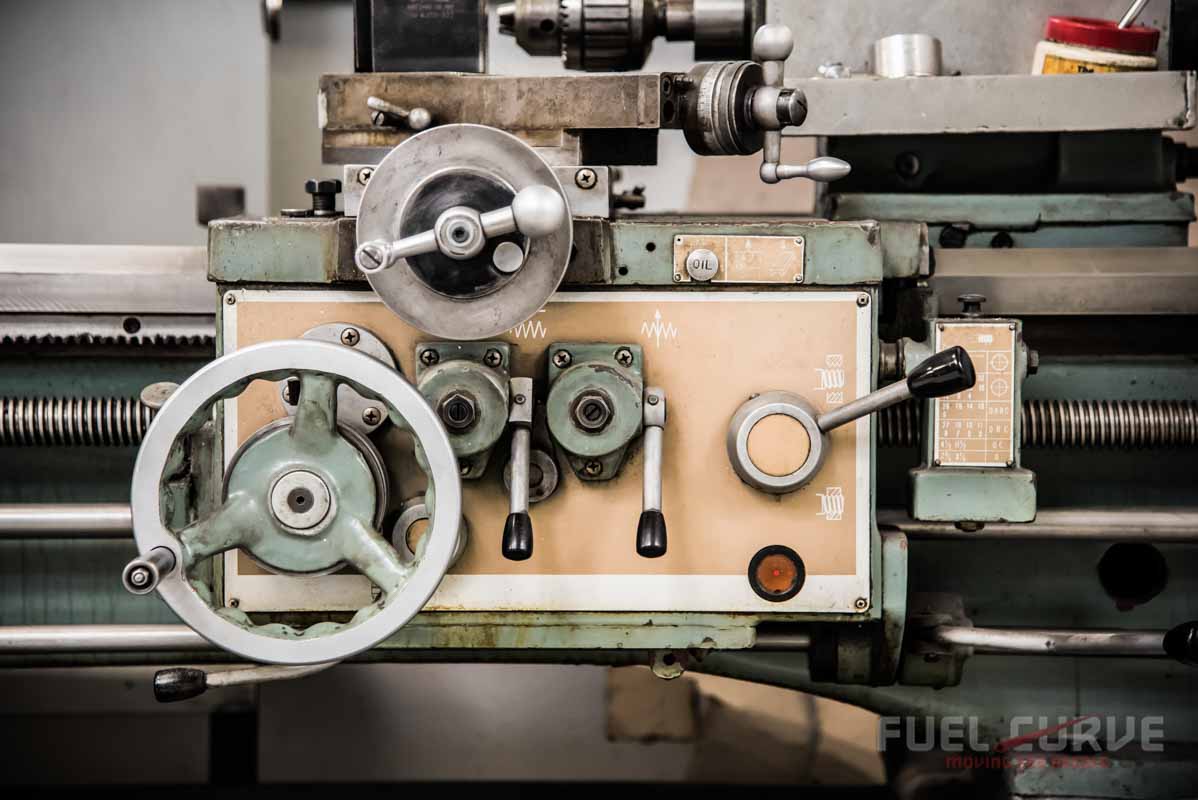

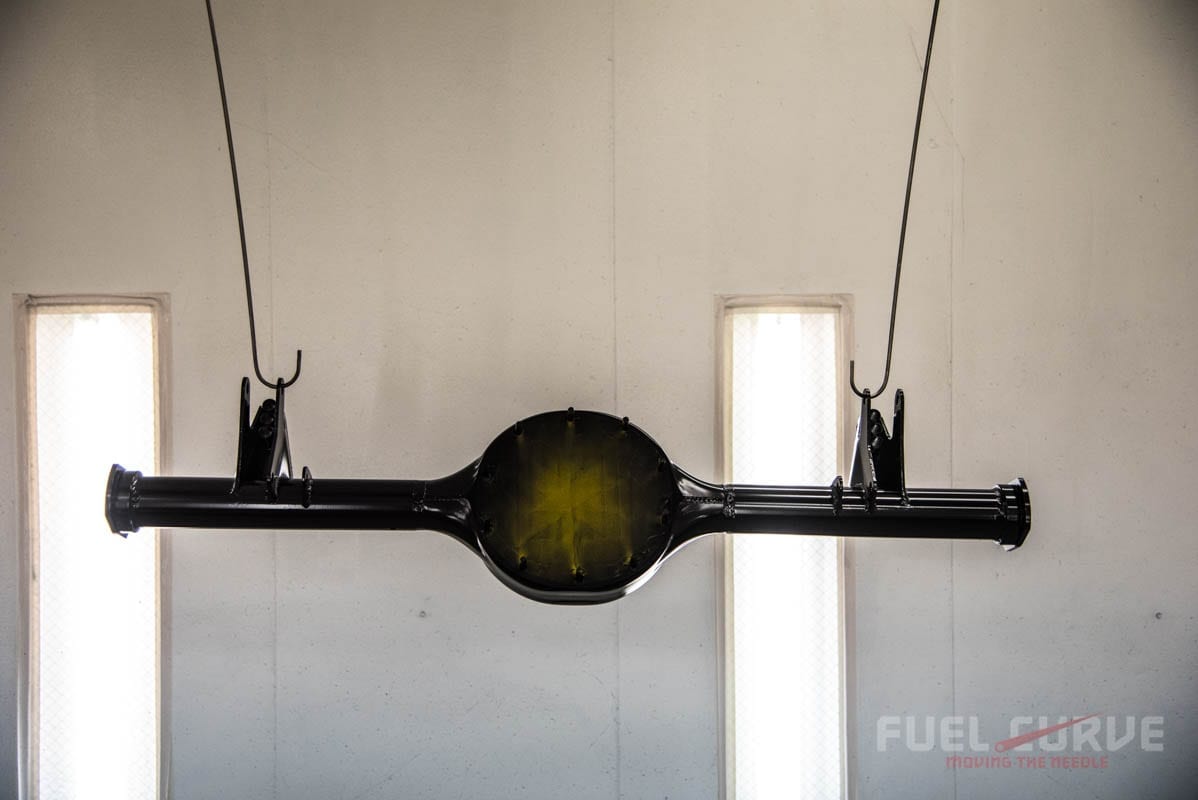

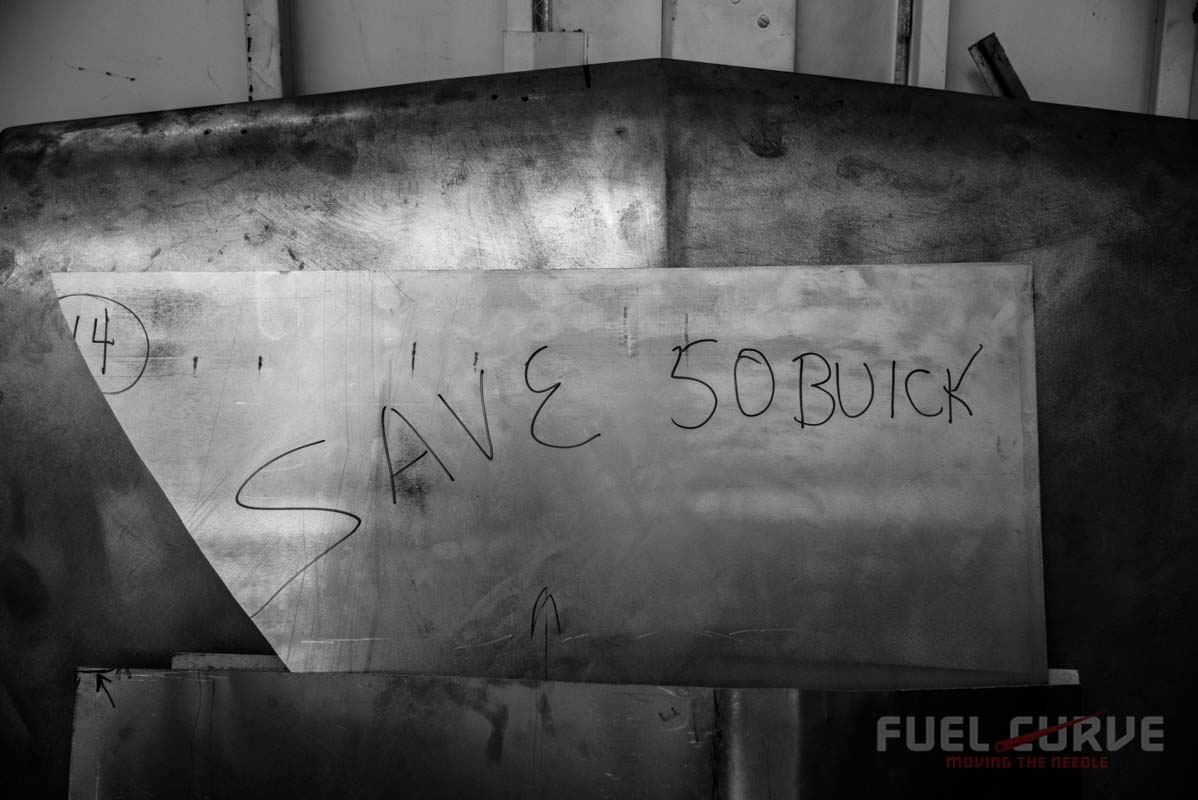

Managing that workload allows the shop to focus on what it does best – meticulous workmanship. For example, all work except interior work is done in-house, from custom-built wiring systems to in-shop fabrication of body panels and chassis. Exhaust systems are hand-built for race, street or show applications. Same for chassis work, depending on what the customer wants. If the project requires a special stance or other options, the chassis will be custom built in-house.

Dominator also paints almost all of its customers’ cars. “The paint’s not really the big issue,” Leonard said. “It’s the body. We started doing all of that in-house because we have control over it.”

RESOURCE MANAGEMENT

Interior work is one service that Dominator does not offer. Because of their location in the greater San Francisco Bay area, though, there are many high-quality shops to use. “That’s the beauty of being in the Bay Area,” Leonard said. “We have access to everybody.”

Leonard said that it doesn’t make sense for him to spend a lot of money on services that can be outsourced to nearby, known suppliers. That holds true for CNC work and other specialty machine work and services. “I learned pretty quick not to blow all your money on that kind of equipment when there are so many people near you who can do that work for you,” Leonard said.

MEETING CUSTOMER GOALS

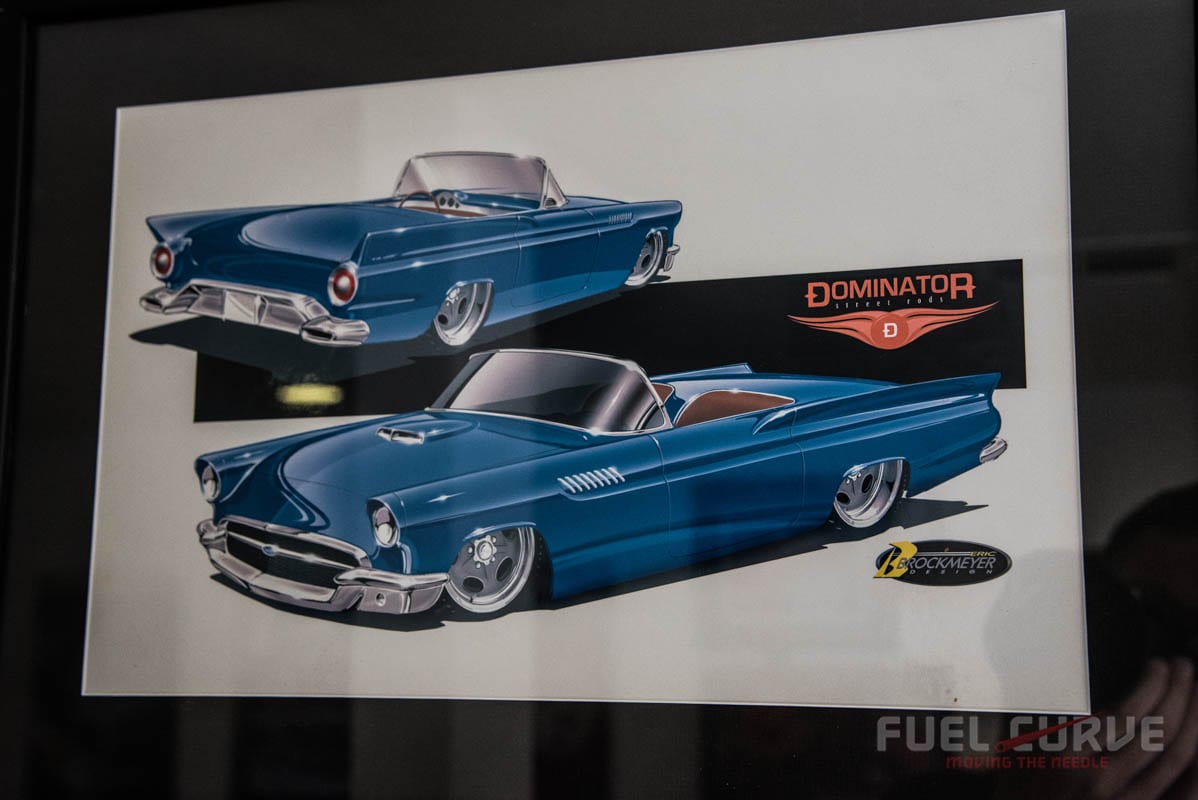

Working with customers to accomplish their goals drives the process on builds at the shop. “The more of an idea that the customer has, the better,” Leonard said. “If they just want to build a car, we’ll work with them to get where they want to go. I’ll give them my opinion, but it’s their choice.” That’s the business part, he said. “You’re in a business, not a hobby. Build the customer the car he wants.”

But customers, and the types of cars they want to build, have changed, so you must be careful with what you promise. “When a customer comes in and says, ‘I want to win,’” Leonard said, “I always tell them there’s no guarantee.”

CREATIVE COLLABORATIONS

As part of his “don’t waste the customer’s money” philosophy, Leonard said he has even been able to produce custom, one-off wheels for customers without breaking the bank by working creatively with the customer and a wheel manufacturer to make everyone happy. “If I’m going to have a custom set of wheels made, I will call a wheel maker and say: ‘OK, we want to make this wheel and have it [exclusively] for a year. After that you can use it.’”

As more seasoned customers are joined by younger generations, customer expectations – and the types of cars they want to build – can change. Leonard said that while customers still want to build cars from the ’30s through the ’50s, more ’60s through ’80s cars are showing up at the door.

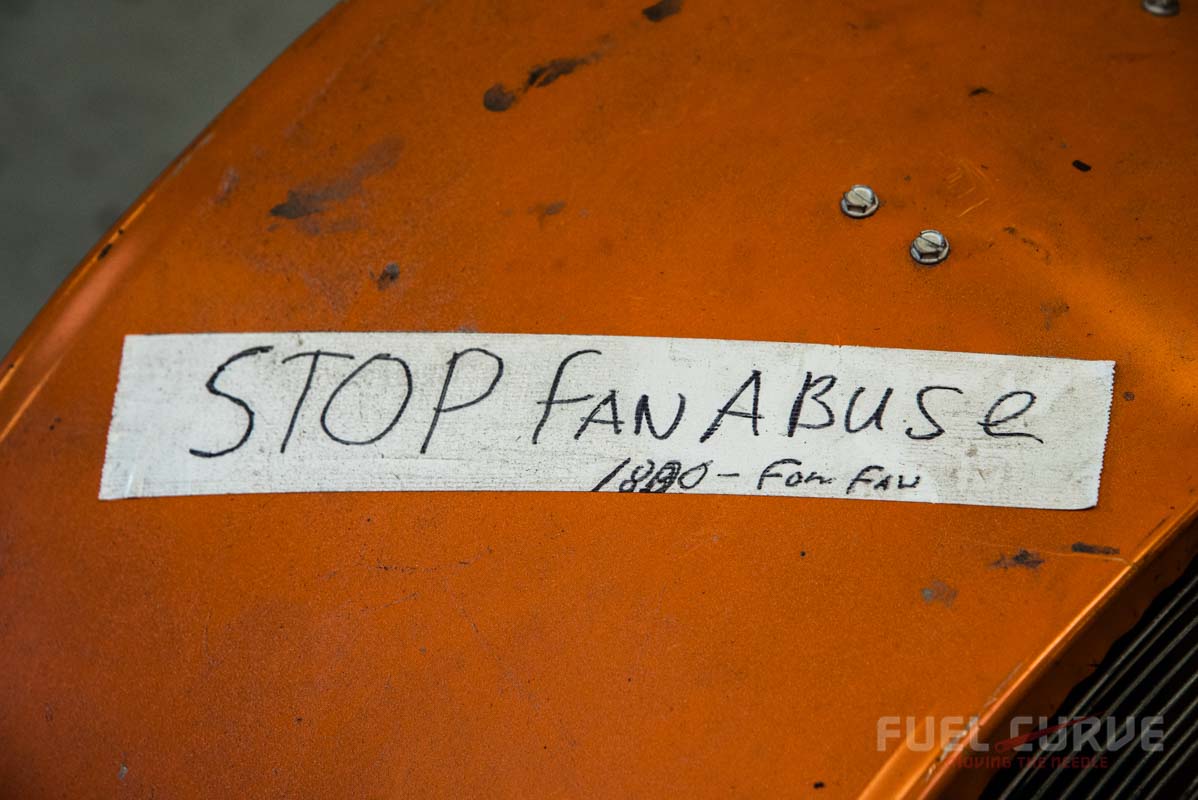

Younger customers also bring a different perspective to the experience. While older customers who came of age in the ‘60s, for example, remember that era’s small selection of aftermarket parts, today’s younger customers have a different outlook. “Customers expect more now,” Leonard said. “We have a younger group of people who don’t do their own work like people used to do. They think they have to buy everything. You can buy it, but we can make it.”

EVOLVING MARKETING STRATEGIES

As customers and their desires change, so does the strategy for marketing the shop. Leonard said he sees more benefit from pulling potential customers toward his website rather than social media. “When we did a lot of stuff on Facebook, we got a lot of ‘will you change the tires on my Camaro’ calls,” he said. “We were having to upset people when we said we couldn’t or wouldn’t do that.”

The long-term success of Dominator Street Rods clearly shows that evolving – from the types of services to strategies to reach future customers – is critical. And, of course, constantly producing striking vehicles helps, too.

Photo Extra!

Photography by John Drummond