Billet Specialties – Supply for Hot Rodding’s Demands

Launched in 1985 at the height of the billet scene by Glenn Grozich, Billet Specialties, Inc. has always had the fashion the automotive aftermarket demands. It’s a tale of perseverance. During the company’s formative years, Grozich’s father was not as optimistic as Glenn. “Why do you want to make car parts?” his father asked as the process was in its infancy. Initially founded as a small product line/extension to his father’s machining and fabricating business, it took some time to get rolling. Eventually, Glenn’s father saw the light and Billet Specialties soon came to dominate the custom wheel and accessories market.

There’s a lot to get excited about here. First and foremost, Billet Specialties is an American manufacturer making products on American soil with a dedicated and hardworking staff, many of whom are passionate car and bike enthusiasts themselves.

To get a sense of the scope of Billet Specialties’ operation, consider this; their facility is over 100,000 square feet of state-of-the-art manufacturing space in La Grange, Illinois. Inside that massive facility you will find: manufacturing areas, 44 CNC machines, assembly and polishing stations, packaging and shipping, not to mention a 5,000 square foot showroom as well as their corporate offices. It’s a hub of activity.

In total, Billet Specialties, Inc makes and stocks over 900 products. How did all this happen? Passion and drive that’s how.

When he was just 13 years old Glenn Grozich started making things in his father’s machine shop. By 14, he had purchased a ’32 Ford 5-window coupe – a car he still has to this day. Roy Brizio redid the car 15 or 20 years ago and it’s still timeless as is his 2002 Goodguys Street Machine of the Year winner – “Chicayne.” You surely remember Chicayne as the twin turbo terror built by fellow Illinoian Troy Trepanier. There are many more hi-performance machines in the Grozich garage too.

“I think the key to our success has been keeping up with market trends and looking ahead to see what’s coming down the road in the future,” Grozich says of how he’s managed to keep his business at the forefront of the industry for over three decades. “And seeing our products on a completed project car is one of my favorite parts of what I do,” he said. “There’s gratification in seeing your products used on some of the most well-done cars in the industry.”

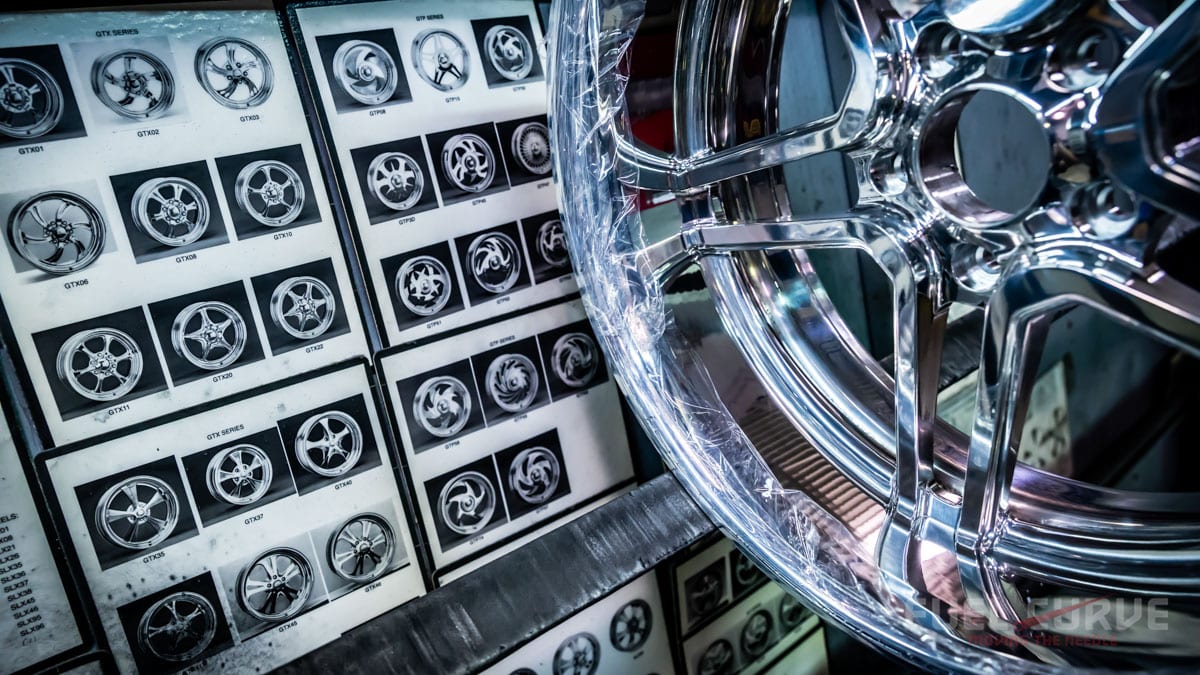

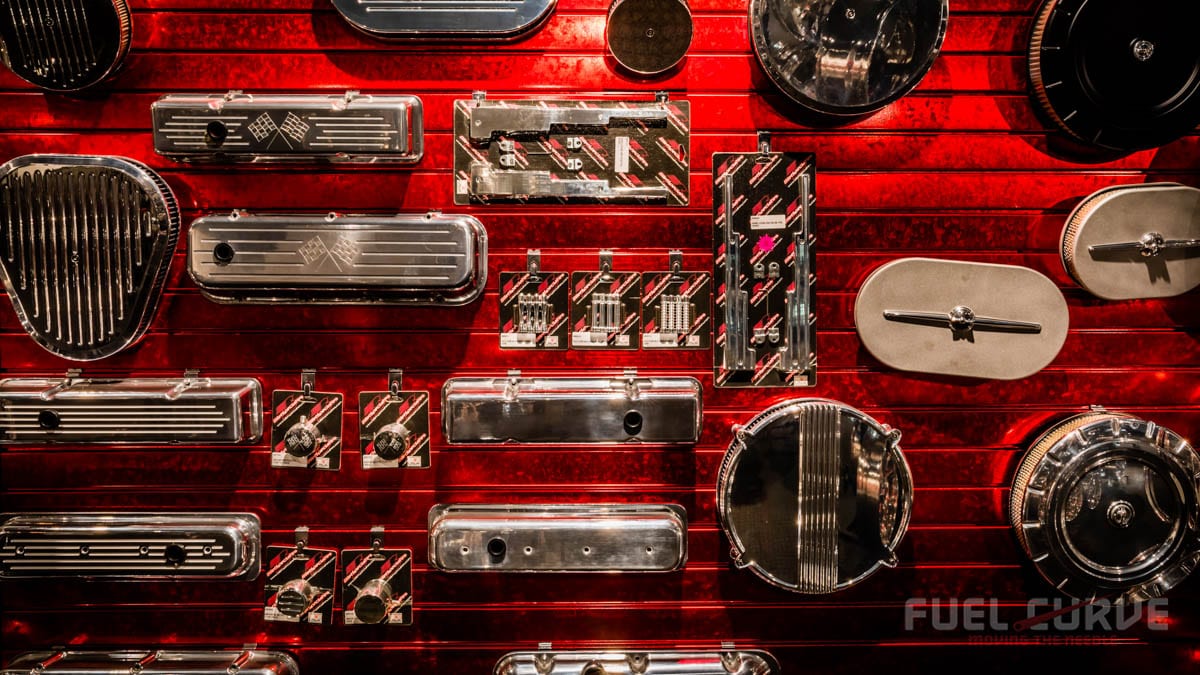

This is reflected in their always expanding product line. Countless billet wheel and accessory designs run the gamut from old school polished billet rims to drag competition wheels to their B-Forged line of wheels which debuted at the 2013 SEMA Show. Engine dress up components, steering wheels, and interior accessories equal their wheels in design and quality. Their patented Tru Trac, Sport Trac and V-Trac systems are likely found on one out of every three cars or trucks at a Goodguys event – if not more.

We recently had the opportunity to look deep inside Billet Specialties, Inc to take you through the different stages of manufacturing. Here’s how they do it.

The Process

Within a 100,000 square foot building there is a team of expert people from engineers, designers, machine operators, polishers, and sales and marketing executives that are the spark to the Billet Specialties engine. These are the hands, minds, and machines that bring hot rodders top-notch custom made wheels and precision ready-to-install accessories. Have a look at this video focusing on the wheels for the Goodguys 2018 Giveaway Mustang. The depth of the wheel construction and finishing process will blow your mind!

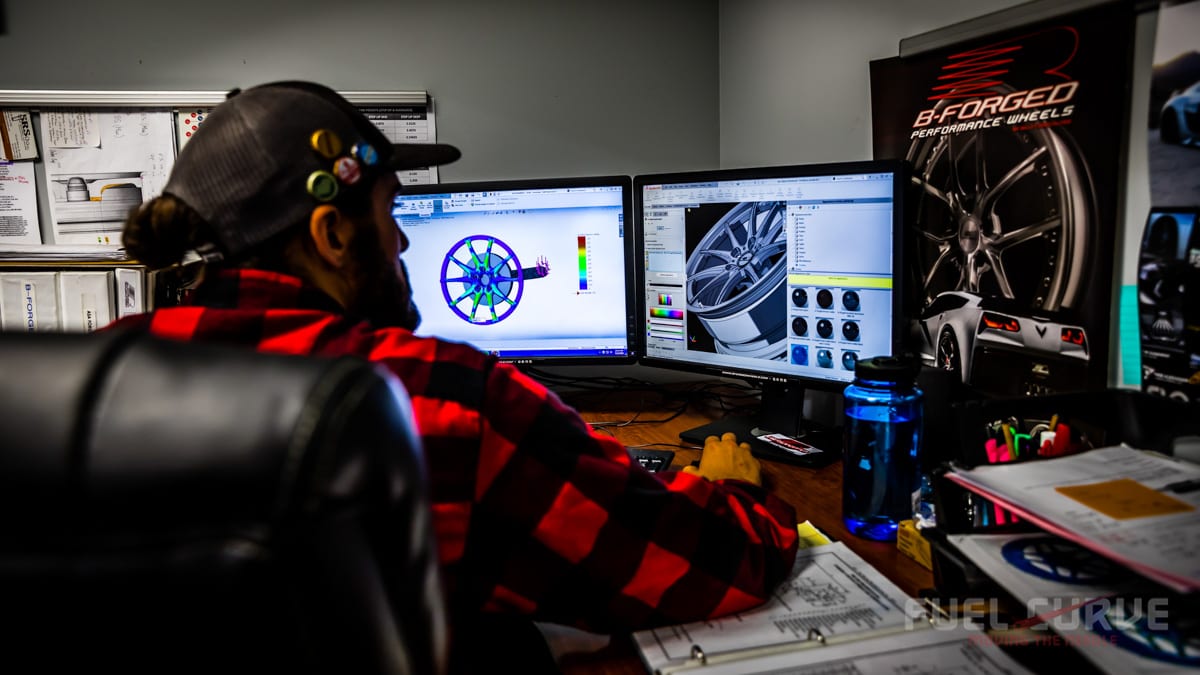

Concept and Design

At Billet Specialties the concept artists, designers, and engineers are reinventing the wheel every day. Finding that sweet spot in form and function, style and safety, nostalgia and ingenuity is the core foundation for these guys when it comes to pushing the bounds of re-inventing the wheel. When it comes to their accessories, like Steering wheels, interior or exterior parts, engine dress up kits, or creating new Tru Trac systems – countless hours are spent in researching the application, assembly, and hardware.

Manufacturing

6061-T6 Aluminum, the same material used in the Pioneer 10 and 11 spacecrafts, can be found in Ultra High Vacuum Chambers here. It’s what Billet Specialties uses in their wheels and accessories. No matter what you are into, luxury imports, exotics, lifted cars on 26’s, mini’s on 15’s, classic hot rods, rubber melting dragsters, or tearing it up in the Salt Flats – all of the products that Billet Specialties manufactures in house comes from raw 6061-T6 Aluminum.

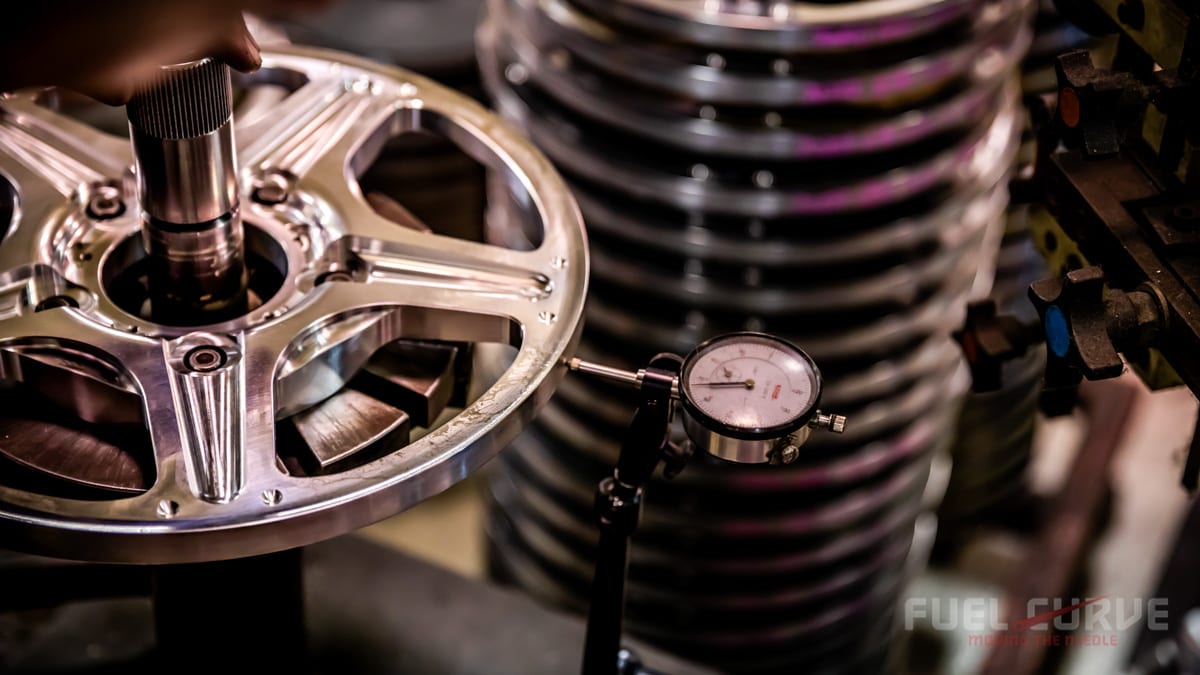

The accessories start as billet aluminum material from plate, bar or extrusions. Skilled hands take these materials through multiple CNC machine operations until they are to the exact specifications of the engineers. Two and three piece wheels ranging from 15” to 26” start from a raw Billet Aluminum Forging. The forgings are loaded in to a lathe for the first and second phase of the new wheel center. These two lathe phases lay the foundation for the HAAS VM3 CNC machines to do their water and tool cutting magic. By following the precise tool paths set forth by the programmers, the machine operators will run the wheel centers through a series of operations giving the wheel its shape, style, and bolt pattern. From here the wheels and accessories are then cleaned and prepped for finishing.

Finishing

Whether polished, anodized, or powder coated the finish is of top priority and to never be an over site at Billet Specialties. Polishing is done by hand to a mirror-quality state and 40-plus powder coat options sets you up to stand out from the rest. Each product (wheels or accessory), is finished one at a time, piece by piece, by hand to perfection.

Assembly

Showroom

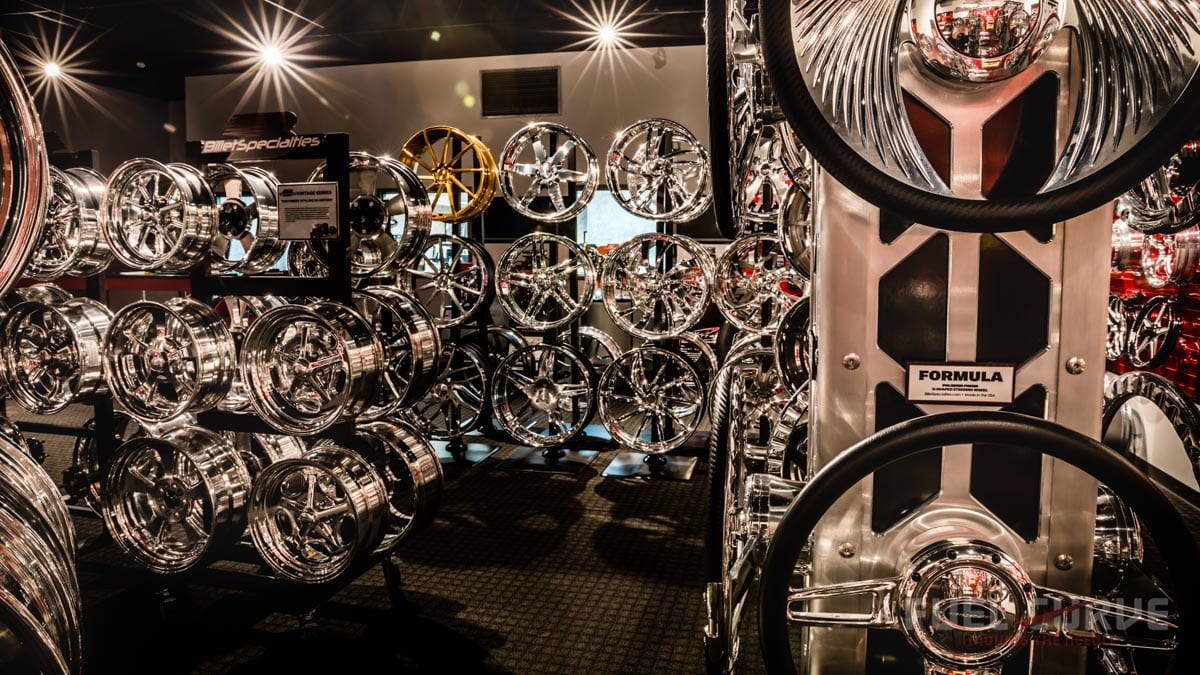

At the end of all this lies a 5,000 square foot Showroom with a wide array of their product line boasting the care, effort, and passion it takes to create each of the products. Billet Specialties’ team of experts invest countless hours to deliver the highest quality wheels and accessories, made in the USA, for the automotive enthusiast.

Count us as believers. It’s cool to know that Glenn’s son Glenn Jr works alongside him, just like he did with his father. Hot rodding tends to come full circle like that.

If you happen to find yourself in the Chicagoland area stop in and see the Billet Specialties facility for yourself. They’re great hosts and great people too.